Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Felt Machine Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Felt Machine Mechanic so you can tailor your answers to impress potential employers.

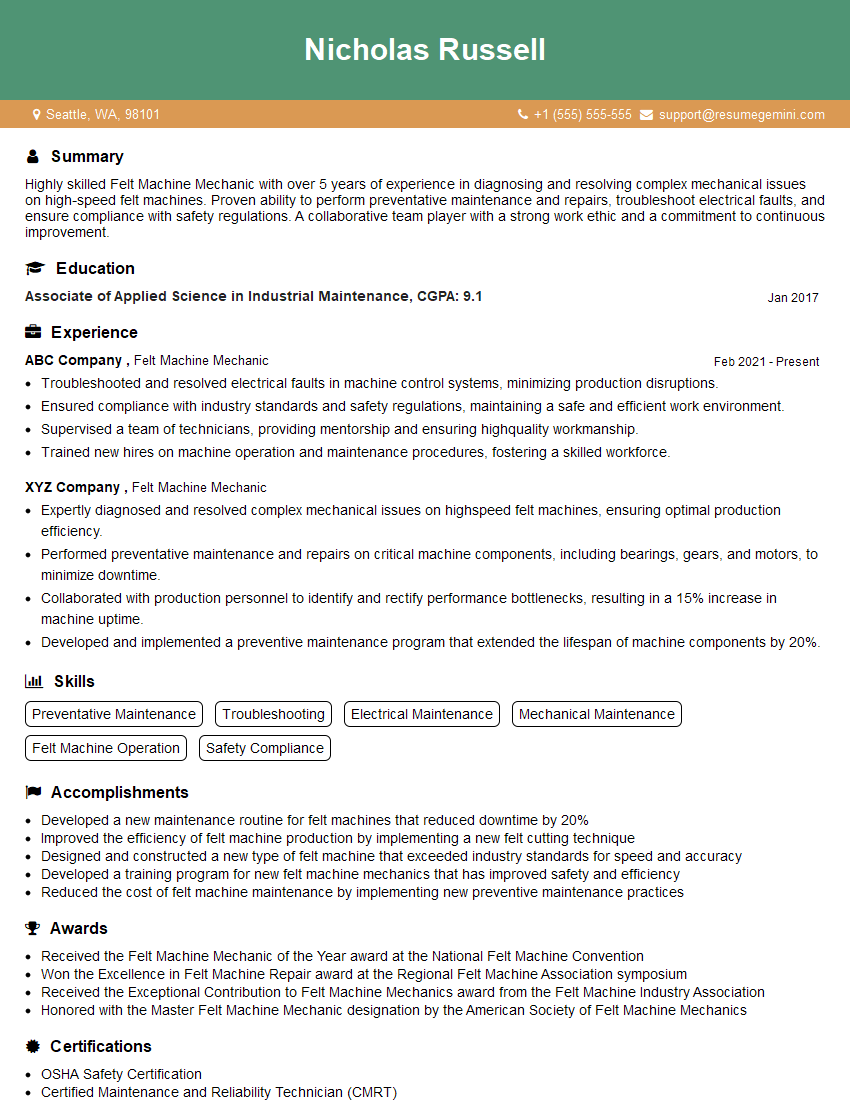

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Felt Machine Mechanic

1. Describe the process of setting up a felt machine for a new job?

- Gather the necessary materials, including the felt, thread, needles, and machine.

- Set up the machine according to the manufacturer’s instructions.

- Thread the machine with the desired thread.

- Insert the felt into the machine.

- Set the machine to the desired speed and stitch length.

- Start sewing the felt.

2. How do you troubleshoot a felt machine that is not sewing properly?

subheading of the answer

- Check the thread tension.

- Check the needle.

- Check the bobbin.

- Check the machine’s settings.

- Clean the machine.

subheading of the answer

- If the problem persists, consult the machine’s manual or contact a qualified technician.

3. What are the different types of felt and how do they differ in their properties?

- Wool felt: Made from 100% wool, it is soft, durable, and has good insulation properties.

- Acrylic felt: Made from synthetic fibers, it is less expensive than wool felt, but it is not as soft or durable.

- Polyester felt: Made from a blend of polyester and wool, it is strong, durable, and resistant to moisture.

- Rayon felt: Made from a blend of rayon and wool, it is soft, smooth, and has a luxurious feel.

4. What are the different types of felt machine needles and when should each type be used?

- Regular needles: Used for general purpose sewing.

- Ballpoint needles: Used for sewing on stretchy fabrics.

- Sharp needles: Used for sewing on delicate fabrics.

- Stretch needles: Used for sewing on very stretchy fabrics.

5. How do you maintain a felt machine to keep it in good working condition?

- Clean the machine regularly.

- Oil the machine regularly.

- Check the machine’s tension regularly.

- Inspect the machine’s needle regularly.

- Have the machine serviced by a qualified technician regularly.

6. What are the safety precautions that should be taken when operating a felt machine?

- Keep your hands away from the needle.

- Do not operate the machine if it is not properly grounded.

- Do not use the machine if it is damaged.

- Wear safety glasses when operating the machine.

- Keep the work area clean and free of clutter.

7. How do you dispose of felt waste properly?

- Dispose of felt waste in a landfill.

- Incinerate felt waste.

- Recycle felt waste.

8. What are the different applications of felt?

- Gaskets and seals

- Filters

- Insulation

- Automotive parts

- Clothing

9. What are the challenges of working as a Felt Machine Mechanic?

- Working with sharp objects.

- Working with heavy machinery.

- Working in a noisy environment.

- Working in a dusty environment.

- Working in a fast-paced environment.

10. What are the rewards of working as a Felt Machine Mechanic?

- Job security

- Good pay

- Benefits

- Opportunity for advancement

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Felt Machine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Felt Machine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Felt Machine Mechanics are responsible for the maintenance and repair of felt machines, which are used to produce felt products. Their key responsibilities include:

1. Inspecting and maintaining felt machines

Inspecting and maintaining felt machines to ensure they are running smoothly and efficiently. This may involve checking for wear and tear, cleaning and lubricating parts, and making minor repairs.

- Inspecting felt machines for wear and tear, loose parts, and other potential problems.

- Cleaning and lubricating felt machines to prevent breakdowns and extend their lifespan.

- Making minor repairs to felt machines, such as replacing worn parts or adjusting settings.

2. Troubleshooting and repairing felt machines

Troubleshooting and repairing felt machines when they break down. This may involve identifying the source of the problem, replacing damaged parts, and making adjustments to the machine’s settings.

- Diagnosing and troubleshooting felt machine problems, such as why the machine is not producing felt or why the felt is not coming out correctly.

- Replacing worn or damaged parts on felt machines, such as belts, bearings, and rollers.

- Adjusting felt machine settings to improve the quality of the felt produced or to increase the efficiency of the machine.

3. Installing and calibrating felt machines

Installing and calibrating felt machines when they are new or have been moved. This may involve assembling the machine, connecting it to power and water supplies, and adjusting the machine’s settings to ensure that it is producing felt of the correct thickness and quality.

- Assembling felt machines according to the manufacturer’s instructions.

- Connecting felt machines to power and water supplies.

- Calibrating felt machines to ensure that they are producing felt of the correct thickness and quality.

4. Training and supervising other employees

Training and supervising other employees who work with felt machines. This may involve teaching them how to operate the machine, how to maintain it, and how to troubleshoot and repair problems.

- Training new employees on how to operate felt machines.

- Supervising other employees who work with felt machines.

- Providing guidance and support to other employees to help them improve their skills and knowledge.

Interview Tips

To ace an interview for a Felt Machine Mechanic position, it is important to:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, in industry publications, and on social media. You can also find information about the position in the job posting and on the company’s website.

- Visit the company’s website to learn about their history, mission, and values.

- Read industry publications to learn about the latest trends and developments in the felt industry.

- Follow the company on social media to get a sense of their culture and to see what they are up to.

2. Prepare your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Practice answering common interview questions with a friend or family member.

- Use the STAR method to answer interview questions. The STAR method stands for Situation, Task, Action, and Result.

3. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the job. Be sure to convey your interest in the position and the company during the interview. You can do this by asking questions about the job and the company, and by sharing your own experiences and skills.

- Smile and make eye contact with the interviewer.

- Be yourself and let your personality shine through.

4. Dress professionally

First impressions matter, so be sure to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed.

- Choose a suit or business casual attire that is appropriate for the company culture.

- Make sure your clothes are clean and pressed.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Felt Machine Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Felt Machine Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.