Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Finished Metal Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

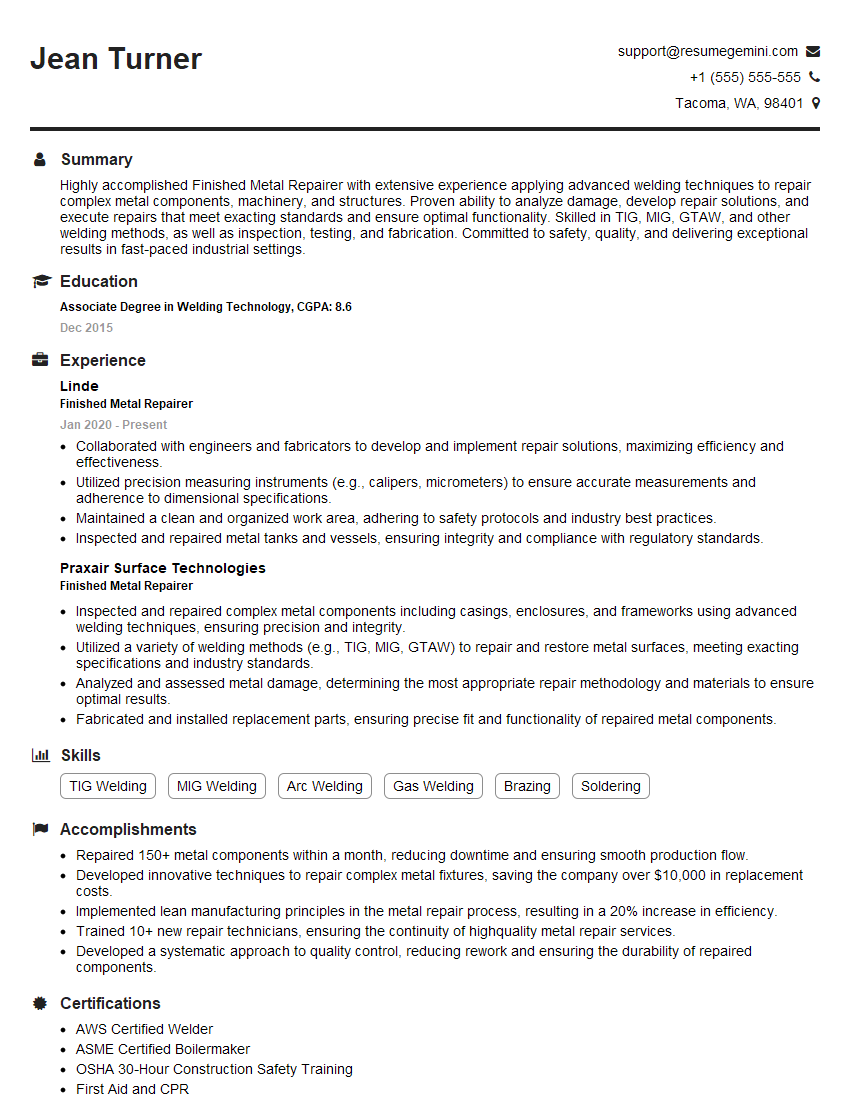

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Finished Metal Repairer

1. What are the different types of metal repair techniques?

There are several metal repair techniques used in the industry, including:

- Welding: Joining two or more pieces of metal together using heat and a filler material.

- Brazing: Joining two or more pieces of metal using a lower-melting-point alloy than the base metal.

- Soldering: Joining two or more pieces of metal using a lower-melting-point alloy than the base metal, but without melting the base metal itself.

- Riveting: Joining two or more pieces of metal using a mechanical fastener, such as a rivet.

- Bolting: Joining two or more pieces of metal using a threaded fastener, such as a bolt and nut.

2. What are the key safety precautions that should be taken when performing metal repair?

Personal Protective Equipment (PPE)

- Wear appropriate PPE, including safety glasses, gloves, and a mask or respirator.

- Ensure that the work area is well-ventilated to avoid inhaling harmful fumes.

Equipment Safety

- Inspect tools and equipment regularly to ensure they are in good working order.

- Use the correct tools for the job and follow manufacturer’s instructions.

- Avoid working with live electrical circuits.

Work Environment

- Keep the work area clean and free of debris.

- Ensure that the work area is well-lit to prevent accidents.

- Be aware of potential hazards, such as sharp edges or hot surfaces.

3. What are the different types of welding methods used in metal repair?

- Arc welding: Uses an electric arc to melt the metal and create a weld.

- Gas welding: Uses a fuel gas and oxygen to melt the metal and create a weld.

- Resistance welding: Uses pressure and an electric current to generate heat and create a weld.

- Laser welding: Uses a concentrated beam of laser light to melt the metal and create a weld.

4. What are the different types of metal finishes that can be applied to repaired metal surfaces?

- Paint: Provides a protective coating and can be used to match the original finish.

- Electroplating: Uses an electric current to deposit a thin layer of metal onto the surface, providing corrosion resistance and improved appearance.

- Powder coating: Applies a dry powder to the surface, which is then cured with heat to create a durable and chemically resistant finish.

- Anodizing: Converts the surface of the metal into a hard, corrosion-resistant oxide layer.

5. What are the common causes of metal corrosion and how can it be prevented?

Causes of Corrosion

- Exposure to moisture and oxygen

- Contact with corrosive chemicals

- Electrochemical reactions

Prevention of Corrosion

- Apply protective coatings, such as paint or electroplating.

- Use corrosion-resistant materials.

- Control the environment to reduce exposure to corrosive elements.

- Implement cathodic protection measures, such as sacrificial anodes.

6. How do you ensure the quality of your metal repair work?

- Follow established repair procedures and industry standards.

- Use high-quality materials and equipment.

- Inspect and test the repaired area to ensure it meets specifications.

- Document the repair process and keep records of all inspections and tests.

7. What are the common challenges faced in metal repair and how do you overcome them?

- Damaged or inaccessible areas: Use specialized tools and techniques to access and repair damaged areas.

- Complex repairs: Break down the repair into smaller steps and consult with experts if needed.

- Matching original finish: Use color charts and consult with the manufacturer to ensure a seamless repair.

- Working with different metals: Understand the properties of different metals and use appropriate techniques for each type.

8. What tools and equipment are essential for a finished metal repairer?

- Welding equipment

- Metalworking tools (e.g., grinder, sander, drill)

- Measuring and layout tools

- Safety gear (e.g., gloves, safety glasses, respirator)

9. How do you stay up-to-date on the latest metal repair techniques and technologies?

- Attend industry conferences and workshops.

- Read trade publications and technical manuals.

- Consult with manufacturers and suppliers for product updates and training.

- Network with other metal repair professionals.

10. How do you handle working with clients and managing their expectations?

- Communicate clearly and establish realistic timelines.

- Listen to the client’s needs and provide options based on their requirements.

- Explain the repair process and potential outcomes.

- Provide regular updates and seek feedback throughout the project.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Finished Metal Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Finished Metal Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Finished Metal Repairers make damaged metal look new again. They possess unparalleled skills and techniques, enabling them to restore and repair metal using various methods and equipment.

1. Damage Assessment and Repair Planning

To initiate the repair process, these experts meticulously assess the damage, evaluating its extent, complexity, and the type of metal involved. Based on their findings, they develop a comprehensive repair plan, selecting the most suitable repair techniques and materials for the job.

- Identify the type and severity of damage to metal surfaces

- Determine the best repair techniques and materials for the specific metal and damage

2. Metal Repair and Restoration

With their exceptional craftsmanship, Finished Metal Repairers restore damaged metal to its original condition. They employ a range of techniques, including welding, soldering, and riveting, to repair cracks, dents, and other imperfections. They also perform surface finishing tasks, such as grinding, polishing, and painting, to achieve a seamless and aesthetically pleasing result.

- Repair cracks, dents, and other imperfections using welding, soldering, and riveting techniques

- Grind, polish, and paint metal surfaces to restore their original appearance

3. Quality Control and Inspection

Finished Metal Repairers take pride in delivering exceptional results. They conduct thorough quality control inspections to ensure that repaired items meet the highest standards of workmanship and aesthetics. They also provide guidance and support to ensure the longevity and durability of their repairs.

- Inspect repaired items to ensure they meet quality standards

- Provide guidance and support to customers on the care and maintenance of repaired items

4. Equipment Maintenance and Safety

To maintain a safe and efficient work environment, Finished Metal Repairers regularly inspect and maintain their equipment, ensuring it is in optimal condition. They also adhere to strict safety protocols to minimize risks and protect themselves and others from potential hazards.

- Inspect and maintain equipment used in metal repair

- Follow safety protocols to minimize risks and protect themselves and others

Interview Tips

To ace your Finished Metal Repairer interview and showcase your skills and experience, consider these valuable tips:

1. Research the Company and Industry

Before the interview, take the time to thoroughly research the company and the metal repair industry. Learn about their values, mission, and the specific requirements of the role. By demonstrating your knowledge and interest, you will make a strong impression on the interviewers.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on trends and best practices

2. Highlight Your Skills and Experience

During the interview, confidently present your skills and experience that align with the key job responsibilities. Provide specific examples of your work, emphasizing your proficiency in metal repair techniques, attention to detail, and ability to meet deadlines. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

- Describe your experience in repairing different types of metal

- Share examples of how you have used your skills to solve complex metal repair challenges

- Highlight your ability to work independently and as part of a team

3. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show the interviewers that you are passionate about metal repair and eager to contribute your skills to their team. Dress professionally and arrive punctually for the interview. Your overall demeanor and conduct will reflect your professionalism and commitment to the role.

- Dress professionally and arrive punctually for the interview

- Maintain eye contact and speak clearly and confidently

- Thank the interviewers for their time and consideration

4. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions. This demonstrates your interest in the role and the company. Prepare questions that are specific to the position and industry, and avoid asking generic questions that could be easily answered through research. Your questions should showcase your curiosity and desire to learn more about the company and the position.

- Ask about the company’s growth plans and industry outlook

- Inquire about the specific challenges and opportunities in the role

- Seek information about the company’s commitment to training and development

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Finished Metal Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Finished Metal Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.