Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Forming Machine Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

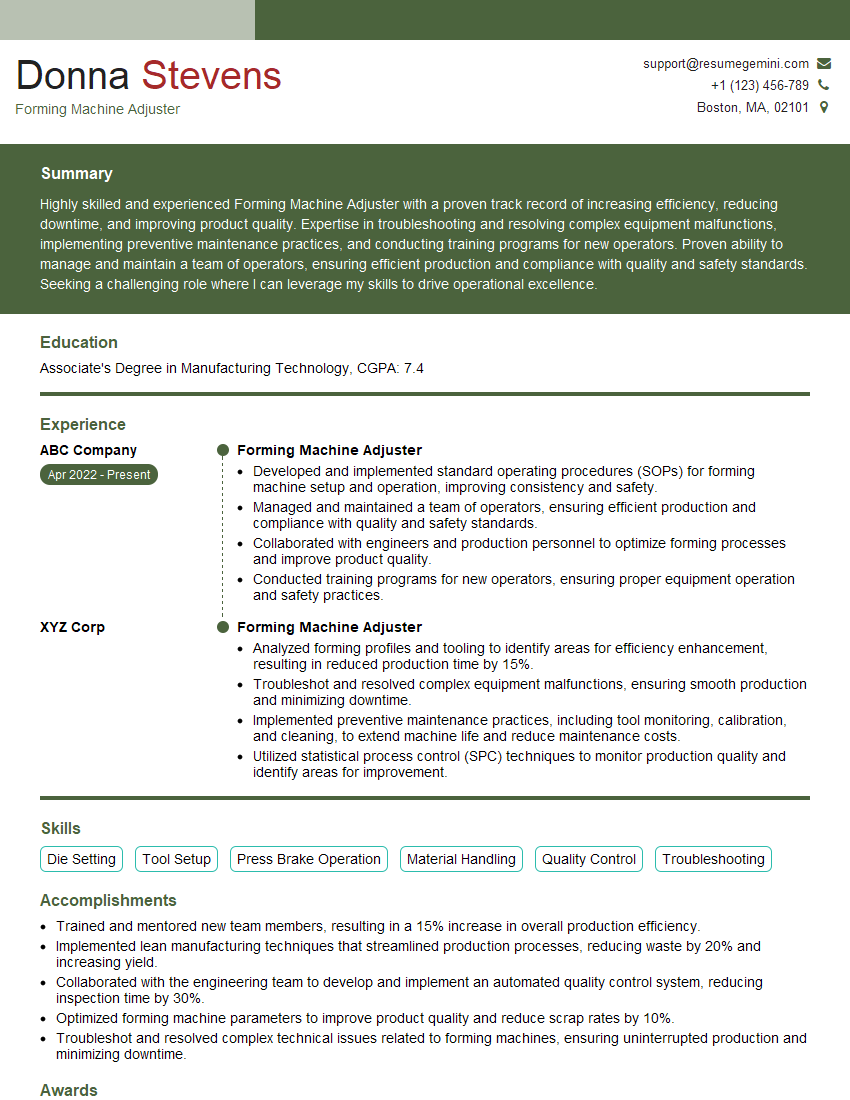

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Forming Machine Adjuster

1. What are the key responsibilities of a Forming Machine Adjuster?

The key responsibilities of a Forming Machine Adjuster include:

- Setting up, adjusting, and maintaining forming machines to produce metal parts according to specifications.

- Monitoring the forming process and making adjustments as needed to ensure that parts are produced to the required quality standards.

- Inspecting finished parts to ensure that they meet specifications and are free of defects.

- Troubleshooting and repairing forming machines when necessary.

- Maintaining a clean and organized work area.

2. What is the difference between a forming machine and a stamping machine?

Stamping Machine

- A stamping machine uses a die to cut or form a shape from a sheet of metal.

- The die is mounted on a press, and the metal is fed into the machine.

- The press applies force to the die, which cuts or forms the metal into the desired shape.

Forming Machine

- A forming machine uses a series of rollers to bend and shape metal into a desired form.

- The metal is fed into the machine, and the rollers bend and shape it into the desired form.

- Forming machines can be used to create a variety of shapes, including cylinders, cones, and tubes.

3. What are the different types of forming machines?

There are many different types of forming machines, including:

- Roll forming machines

- Press brake machines

- Folding machines

- Shearing machines

- Punching machines

4. What are the safety precautions that must be taken when operating a forming machine?

When operating a forming machine, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as safety glasses, earplugs, and gloves.

- Keep hands and other body parts away from moving parts.

- Never operate a forming machine if it is not properly guarded.

- Be aware of the location of emergency stop buttons and know how to use them.

- Follow all manufacturer’s instructions for safe operation of the forming machine.

5. What are some common problems that can occur when operating a forming machine?

Some common problems that can occur when operating a forming machine include:

- The machine may not produce parts to the desired quality standards.

- The machine may jam or break down.

- The machine may be damaged if it is not properly operated or maintained.

6. How do you troubleshoot a forming machine that is not producing parts to the desired quality standards?

To troubleshoot a forming machine that is not producing parts to the desired quality standards, I would first check the following:

- The machine settings

- The condition of the dies or tooling

- The material being used

- The condition of the machine itself

7. How do you repair a forming machine that has jammed or broken down?

To repair a forming machine that has jammed or broken down, I would first attempt to clear the jam or fix the breakdown myself.

- If I am unable to do so, I would then contact a qualified technician for assistance.

8. How do you maintain a forming machine to prevent problems from occurring?

To maintain a forming machine to prevent problems from occurring, I would perform the following tasks:

- Regularly clean and lubricate the machine.

- Inspect the machine for any signs of wear or damage.

- Calibrate the machine according to the manufacturer’s instructions.

- Follow all manufacturer’s instructions for maintenance of the forming machine.

9. What are some of the challenges of working as a Forming Machine Adjuster?

Some of the challenges of working as a Forming Machine Adjuster include:

- The work can be physically demanding.

- The work can be repetitive.

- The work can be dangerous if proper safety precautions are not taken.

- The work can be stressful if there is a high demand for production.

10. What are some of the rewards of working as a Forming Machine Adjuster?

Some of the rewards of working as a Forming Machine Adjuster include:

- The work can be satisfying if you enjoy working with your hands.

- The work can be challenging if you are looking for a job that requires you to use your problem-solving skills.

- The work can be rewarding if you are proud of the products that you help to produce.

- The work can be well-paying if you have the skills and experience that are required for the job.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Forming Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Forming Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Forming Machine Adjusters are responsible for operating, maintaining, and repairing forming machines that shape and mold metal or plastic components. Their main goal is to ensure the smooth and efficient operation of production lines.

1. Machine Operation and Adjustment

Adjust and calibrate forming machines to meet precise specifications for product dimensions and quality.

- Monitor machine performance and make necessary adjustments to optimize production.

- Identify and troubleshoot malfunctions in forming machines and take corrective actions.

2. Production and Quality Control

Monitor production output to ensure that it meets quantity and quality requirements.

- Inspect finished products for defects and ensure they comply with established standards.

- Maintain detailed records of production and quality data for analysis and improvements.

3. Preventive Maintenance

Perform scheduled and unscheduled maintenance tasks to minimize downtime and maintain machine efficiency.

- Lubricate and clean machines, replace worn parts, and conduct regular inspections.

- Follow established maintenance procedures and safety protocols.

4. Troubleshooting and Repair

Diagnose and resolve mechanical, electrical, and hydraulic issues in forming machines.

- Use diagnostic tools and techniques to identify the root cause of problems.

- Repair or replace damaged components, ensuring that machines operate at optimal performance.

Interview Tips

Preparing for an interview for a Forming Machine Adjuster position requires thorough research and a clear understanding of both the industry and your qualifications. Here are some key tips to help you ace the interview.

1. Know the Industry

Research the forming industry and specific techniques used in metal or plastic forming. Familiarize yourself with common forming processes, such as stamping, bending, and rolling.

- Review industry publications and websites.

- Attend industry events and workshops.

2. Highlight Relevant Skills

Emphasize your technical skills in operating and maintaining forming machines. Quantify your experience with specific models or types of machines, providing examples of successful adjustments or repairs.

- Mention any certifications or training you have in forming machine operation.

- Discuss your understanding of hydraulic, electrical, and mechanical systems.

3. Demonstrate Problem-Solving Abilities

Forming Machine Adjusters are often responsible for troubleshooting and repairing complex issues. Prepare to discuss your problem-solving approach and provide examples of how you have successfully diagnosed and resolved problems in the past.

- Use the STAR method (Situation, Task, Action, Result) to describe a challenging situation and how you overcame it.

- Emphasize your ability to think critically and find innovative solutions.

4. Show Enthusiasm and Eagerness to Learn

Forming Machine Adjusters need to be adaptable and willing to learn new technologies. Express your enthusiasm for the industry and your desire to continue developing your skills. Discuss any specific areas where you are interested in expanding your knowledge.

- Mention your interest in cutting-edge forming technologies or advancements.

- Share your willingness to take on new challenges and responsibilities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Forming Machine Adjuster, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Forming Machine Adjuster positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.