Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Foundry Equipment Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Equipment Mechanic

1. Describe the process of setting up and aligning a jolt squeeze molding machine.

The process of setting up and aligning a jolt squeeze molding machine involves several key steps:

- Inspect and clean the machine: Ensure the machine is in good working condition and free of any debris or damage.

- Adjust the pattern height: Set the pattern height to match the desired mold size.

- Position the flask and pattern: Place the flask on the machine table and align the pattern centrally.

- Align the jolt and squeeze cylinders: Adjust the cylinder positions to ensure they are perpendicular to the pattern and flask.

- Set the jolt and squeeze pressures: Adjust the air pressure regulators to achieve the desired jolt and squeeze forces.

- Test the machine: Perform a test run to ensure the machine is operating correctly and producing consistent molds.

2. How do you troubleshoot a jolt squeeze molding machine that is producing defective molds?

Identifying the problem:

- Check the pattern: Ensure the pattern is undamaged and free of any defects.

- Inspect the flask: Inspect the flask for any damage or deformation.

- Verify the alignment: Check if the jolt and squeeze cylinders are properly aligned.

- Adjust the pressures: Ensure the jolt and squeeze pressures are set correctly.

Fixing the issue:

- Repair or replace the pattern: If the pattern is damaged, repair or replace it.

- Replace the flask: If the flask is damaged, replace it with a new one.

- Realign the cylinders: Adjust the cylinders to ensure they are perpendicular to the pattern and flask.

- Reset the pressures: Adjust the air pressure regulators to achieve the desired jolt and squeeze forces.

3. Explain the different types of molding sands and their properties.

There are various types of molding sands used in foundries, each with its unique properties:

- Green sand: A mixture of sand, clay, and water, used for most ferrous castings.

- Resin-bonded sand: Sand bonded with a thermosetting resin, offering high strength and durability.

- No-bake sand: Sand mixed with a chemical binder that hardens without baking, reducing production time.

- Clay-bonded sand: Sand bonded with clay, used for heavy castings due to its high strength and refractoriness.

- Oil-bonded sand: Sand bonded with an oil-based binder, providing good surface finish and accuracy.

4. Describe the safety precautions that must be followed when working with molten metal.

- Wear proper personal protective equipment (PPE): Including heat-resistant clothing, gloves, and safety glasses.

- Handle molten metal with care: Use tongs or other equipment to minimize contact.

- Maintain a clean and organized work area: Remove tripping hazards and ensure proper ventilation.

- Be aware of potential hazards: Identify and mitigate any risks, such as spatter or fumes.

- Follow established safety protocols: Adhere to all company and industry safety regulations.

5. Explain the purpose and operation of a cupola furnace.

A cupola furnace is a cylindrical, vertical furnace used to melt iron and other ferrous metals:

- Charging: Iron ore, coke, and flux are charged into the furnace through the top.

- Melting: Coke combustion provides heat to melt the iron, which collects in the crucible at the bottom.

- Tapping: Molten iron is tapped from the crucible for pouring into molds.

- Blast: A blast of air is supplied through tuyeres to support combustion and increase furnace efficiency.

6. Describe the different methods of casting metal and their advantages and disadvantages.

- Sand casting: Pouring molten metal into a mold made of sand, offering flexibility and low cost.

- Investment casting: Pouring molten metal into a mold made of a refractory material, allowing for intricate designs.

- Die casting: Forcing molten metal under pressure into a metal mold, producing high-precision parts.

- Permanent mold casting: Pouring molten metal into a metal mold that can be reused multiple times.

- Centrifugal casting: Pouring molten metal into a rotating mold, resulting in a dense and uniform structure.

7. Explain the importance of metallurgy in the foundry industry.

- Material selection: Metallurgy helps determine the appropriate metal alloys for specific casting applications.

- Process optimization: Understanding metallurgy allows foundries to optimize casting processes for different metals.

- Quality control: Metallurgy enables analysis and testing of castings to ensure material integrity and performance.

- Research and development: Metallurgy drives innovation in casting techniques and metal alloys.

8. Describe the role of quality control in a foundry.

- Incoming inspection: Verifying the quality of incoming materials, such as sand, metal, and patterns.

- In-process inspection: Monitoring casting processes to ensure adherence to specifications.

- Final inspection: Evaluating finished castings for dimensional accuracy, surface finish, and other quality criteria.

- Non-destructive testing: Employing techniques such as radiography and ultrasonic testing to assess internal quality.

- Corrective action: Identifying and addressing any quality issues to prevent their recurrence.

9. Explain the principles of preventive maintenance for foundry equipment.

- Scheduled inspections: Regularly checking equipment for wear, damage, and potential issues.

- Lubrication: Regularly lubricating moving parts to minimize friction and wear.

- Cleaning: Keeping equipment clean to prevent buildup and corrosion.

- Calibration: Ensuring that equipment is calibrated to maintain accuracy and performance.

- Record keeping: Maintaining detailed records of inspections and maintenance actions for future reference.

10. Describe your experience in troubleshooting and repairing foundry equipment.

Throughout my career, I have encountered various equipment issues and developed a systematic approach to troubleshooting and repair:

- Identify the problem: Gather information, observe the equipment, and consult technical documentation.

- Isolate the root cause: Determine the specific component or system causing the issue.

- Perform repairs: Safely and efficiently repair or replace faulty components.

- Test and verify: Conduct thorough testing to ensure the equipment is functioning properly after repairs.

- Document and report: Maintain detailed records of troubleshooting and repair actions for future reference.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Equipment Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Equipment Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

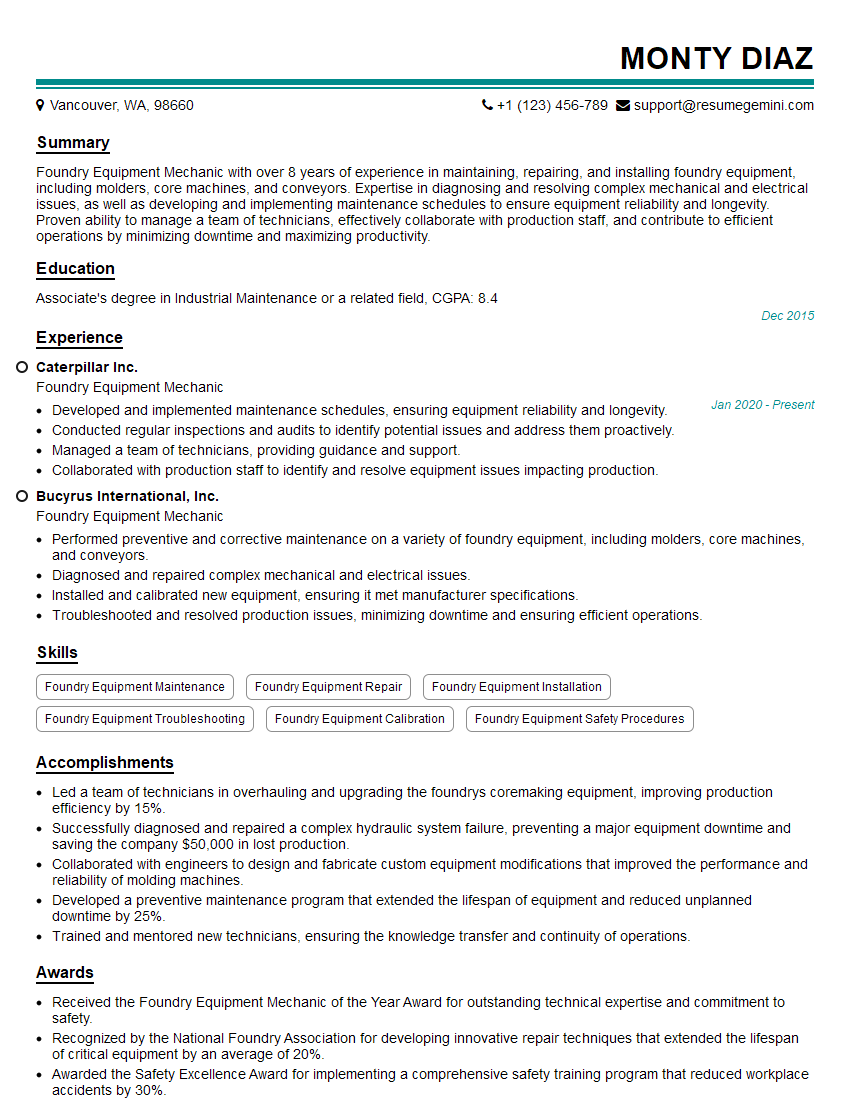

Key Job Responsibilities

Foundry Equipment Mechanics play a vital role in ensuring the smooth operation of foundry equipment, ensuring production efficiency and safety.

1. Equipment Maintenance and Repair

Inspect, diagnose, and repair a wide range of foundry equipment, including molding machines, core making machines, melting furnaces, and conveyors.

- Troubleshoot mechanical, electrical, and hydraulic systems.

- Replace worn or damaged parts, lubricate components, and adjust settings.

2. Equipment Installation and Commissioning

Install and commission new or overhauled foundry equipment, ensuring proper operation and compliance with safety regulations.

- Read and interpret technical drawings and specifications.

- Align and level equipment, connect electrical and mechanical components.

3. Preventive Maintenance

Develop and implement preventive maintenance schedules to minimize equipment downtime and extend equipment lifespan.

- Perform routine inspections, lubrication, and adjustments.

- Monitor equipment performance and identify potential issues.

4. Safety and Compliance

Maintain a safe work environment by following safety protocols and ensuring equipment meets regulatory standards.

- Operate equipment in accordance with safety procedures.

- Report and correct potential safety hazards.

Interview Tips

Acing an interview for a Foundry Equipment Mechanic position requires a combination of technical knowledge, practical experience, and effective communication skills.

1. Research the Company and Position

Thoroughly research the foundry industry, the specific company, and the job requirements. This will help you tailor your answers and demonstrate your understanding of the role.

2. Highlight Your Technical Skills

Emphasize your knowledge of foundry equipment, including its mechanics, electrical systems, and hydraulics. Provide specific examples of your troubleshooting and repair experiences.

3. Showcase Your Practical Experience

Quantify your experience by providing concrete examples of projects and tasks you’ve completed. Use numbers and metrics to demonstrate your impact on equipment uptime and productivity.

4. Discuss Safety and Compliance

Emphasize your commitment to safety and compliance. Discuss your understanding of industry regulations and your experience in maintaining a safe work environment.

5. Practice Commonly Asked Questions

Prepare for common interview questions, such as:

- “Describe your experience troubleshooting and repairing foundry equipment.”

- “How do you ensure the safety and compliance of equipment?”

- “What are your preferred methods for performing preventive maintenance?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Foundry Equipment Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Foundry Equipment Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.