Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Harness Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

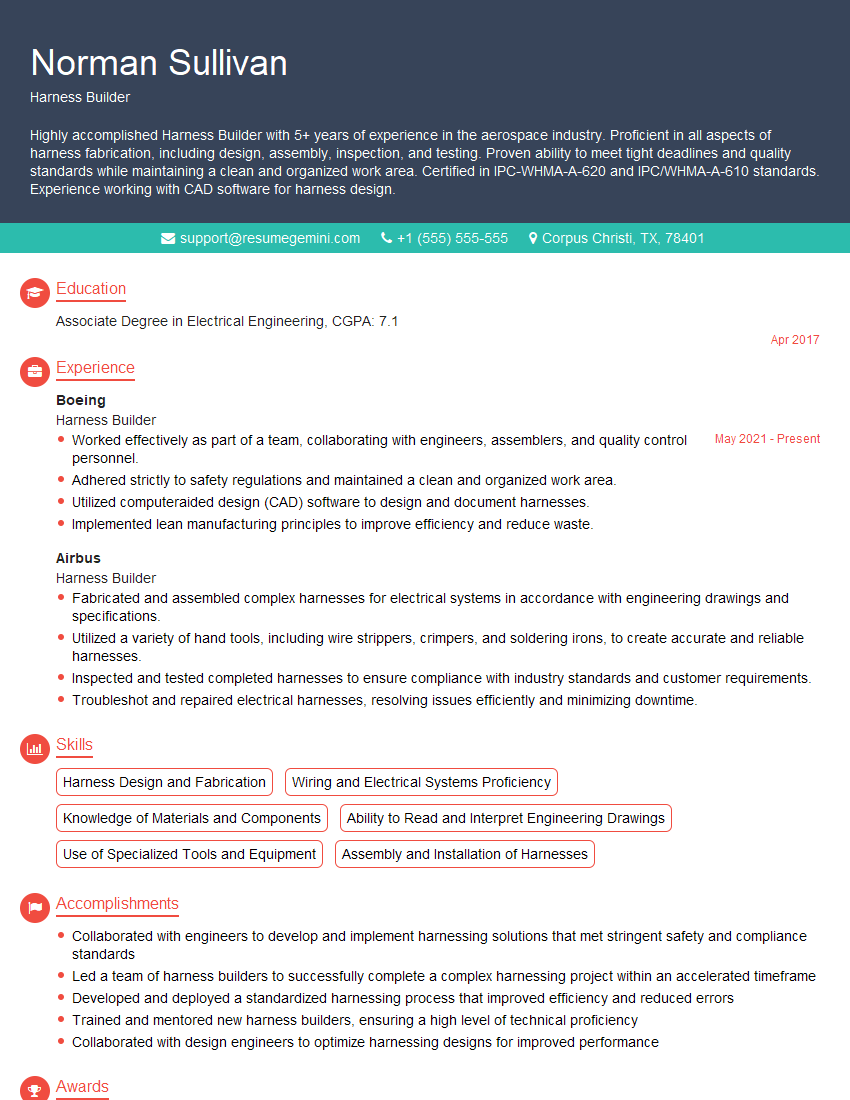

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Harness Builder

1. What is a Harness Builder and what are its key responsibilities?

A Harness Builder is responsible for designing, developing, and maintaining wire harnesses for a variety of electrical systems. Key responsibilities include:

- Reading and interpreting electrical schematics

- Selecting and cutting wires to the correct length

- Crimping and soldering wires together

- Inspecting and testing harnesses for quality

- Troubleshooting and repairing harnesses

2. What are the different types of wire harnesses?

There are many different types of wire harnesses, each with its own specific purpose. Some of the most common types include:

- Power harnesses

- Signal harnesses

- Data harnesses

- Control harnesses

- Automotive harnesses

3. What are the different materials used in wire harnesses?

Wire harnesses are made from a variety of materials, each with its own unique properties. Some of the most common materials include:

- Copper

- Aluminum

- Steel

- Nickel

- Polyvinyl chloride (PVC)

4. What are the different tools and equipment used in wire harness building?

Harness builders use a variety of tools and equipment to perform their jobs. Some of the most common tools include:

- Wire cutters

- Wire strippers

- Crimping tools

- Soldering irons

- Multimeters

5. What are the safety precautions that must be taken when working with wire harnesses?

Working with wire harnesses can be dangerous if proper safety precautions are not taken. Some of the most important safety precautions include:

- Wearing appropriate safety gear, such as gloves and safety glasses

- Working in a well-ventilated area

- Using proper tools and equipment

- Following all safety procedures

6. What are the quality control procedures that must be followed when building wire harnesses?

It is important to follow strict quality control procedures when building wire harnesses to ensure that they are safe and reliable. Some of the most common quality control procedures include:

- Inspecting all materials before use

- Testing all harnesses before they are shipped

- Maintaining a clean work area

- Following all applicable industry standards

7. What are the new trends in wire harness building?

The wire harness industry is constantly evolving, with new trends emerging all the time. Some of the most recent trends include:

- The use of automated wire harnessing machines

- The development of new materials

- The adoption of new safety standards

8. How does a Harness Builder use Harness Builder software?

Harness Builder software is a computer-aided design (CAD) software that helps harness builders design, develop, and document wire harnesses. Harness Builder software can be used to create 3D models of wire harnesses, generate wire lists, and create documentation. It can also be used to simulate the electrical performance of wire harnesses, ensuring that they meet the required specifications.

9. What are the benefits of using Harness Builder software?

Harness Builder software offers a number of benefits for harness builders, including:

- Increased productivity

- Improved accuracy

- Reduced costs

- Enhanced collaboration

10. What are the challenges of being a Harness Builder?

There are a number of challenges that harness builders face on a daily basis, including:

- Working with complex electrical schematics

- Ensuring that harnesses meet all applicable safety standards

- Keeping up with the latest trends in the industry

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Harness Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Harness Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Harness Builders are responsible for the design, development, and maintenance of harnesses, which are used to connect electrical components in various industries. Their key job responsibilities include:

1. Design and Development of Harnesses

Harness Builders design and develop electrical harnesses according to customer specifications, ensuring that they meet technical requirements and industry standards.

- Analyze customer requirements and specifications.

- Select and procure appropriate materials, including wires, connectors, and other components.

- Create technical drawings and documentation using software tools like AutoCAD or SolidWorks.

- Develop prototypes and conduct testing to ensure harness functionality and performance.

2. Harness Assembly and Fabrication

Harness Builders assemble and fabricate harnesses using a variety of techniques and tools, including crimping, soldering, and taping.

- Cut and strip wires to specified lengths.

- Crimp and solder connectors to wire ends.

- Assemble and bundle wires into harnesses according to design specifications.

- Secure harnesses using tie wraps, clamps, or other fastening devices.

3. Testing and Inspection

Harness Builders perform thorough testing and inspection to ensure harness accuracy, reliability, and compliance with standards.

- Conduct electrical continuity and insulation resistance tests using specialized equipment.

- Inspect harnesses for defects, such as broken wires, damaged insulation, or loose connections.

- Verify harness performance against specifications and standards.

- Document test results and issue inspection certificates.

4. Manufacturing Optimization

Harness Builders continuously seek ways to improve manufacturing processes and reduce production costs.

- Analyze production data to identify inefficiencies and bottlenecks.

- Implement lean manufacturing techniques, such as 5S and Kanban.

- Automate tasks and optimize workflows using specialized tools and machinery.

- Train and support other team members to improve overall efficiency.

Interview Tips

To ace the interview for a Harness Builder position, candidates should prepare thoroughly and demonstrate their technical skills, problem-solving abilities, and commitment to quality.

1. Research the Company and Industry

Candidates should research the company’s background, products, and industry to show that they have a genuine interest in the organization and the field.

- Visit the company website and read industry publications.

- Network with professionals in the industry to gain insights.

- Prepare questions that demonstrate your understanding of the company and the role.

2. Highlight Technical Skills and Experience

Candidates should emphasize their technical skills and experience in harness design, fabrication, and testing.

- Provide specific examples of projects where you applied your skills.

- Quantify your accomplishments, such as the number of harnesses produced or the percentage of defects reduced.

- Be prepared to discuss industry standards and best practices.

3. Showcase Problem-Solving Abilities

Harness Builders often encounter challenges during the design and fabrication process, so it’s essential to showcase your problem-solving abilities.

- Describe situations where you identified and resolved harness issues.

- Explain your approach to troubleshooting and finding solutions.

- Discuss how you apply critical thinking and logical reasoning to your work.

4. Emphasize Attention to Detail and Quality

Harness Builders must be meticulous and pay close attention to detail to ensure the accuracy and reliability of their work.

- Provide examples of your commitment to quality and adherence to standards.

- Discuss your inspection and testing procedures.

- Explain how you ensure that harnesses meet customer specifications and industry requirements.

5. Prepare for Common Interview Questions

Be prepared to answer common interview questions, such as:

- Tell me about your experience in harness design and fabrication.

- Describe a challenging project you worked on and how you overcame the obstacles.

- What quality control measures do you implement to ensure the accuracy of your work?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Harness Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!