Are you gearing up for an interview for a Knitting Machine Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Knitting Machine Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

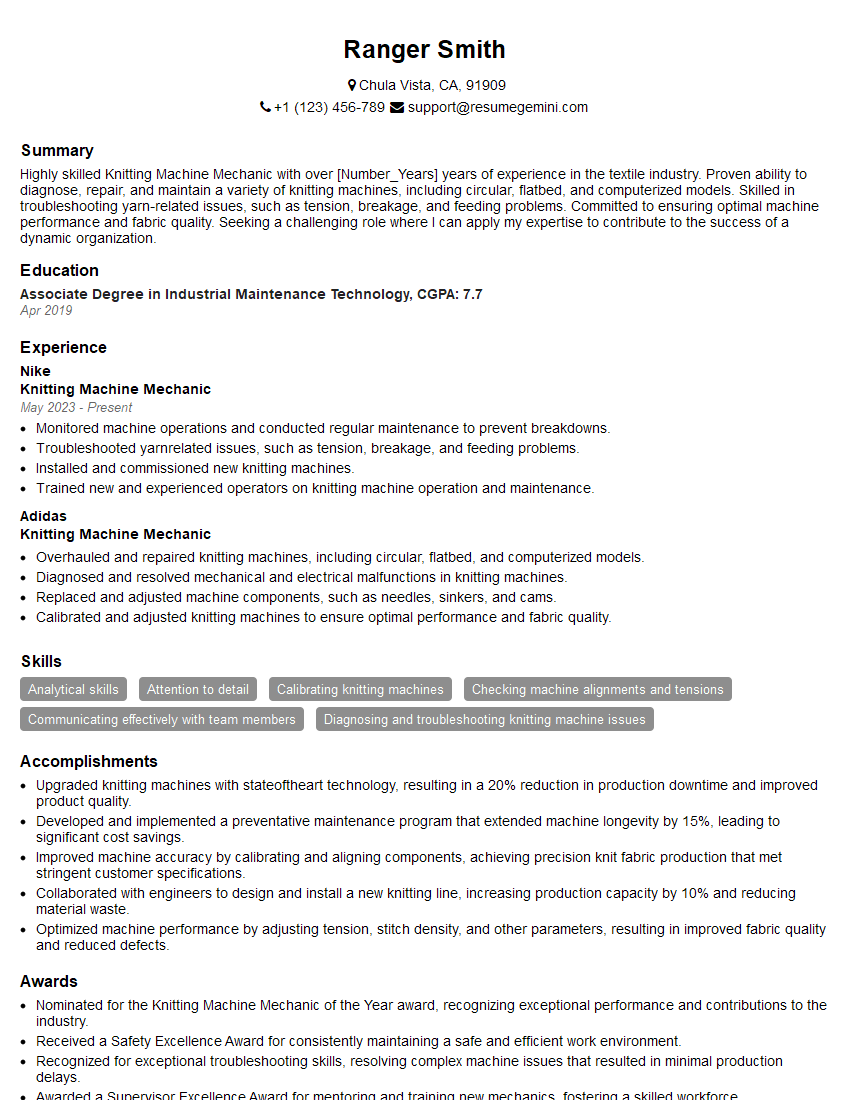

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Knitting Machine Mechanic

1. What are the key components of a knitting machine?

- Knitting elements: needles, sinkers, and jacks

- Yarn feed system: tensioners, guides, and yarn carriers

- Knitting carriage: moves the knitting elements and creates loops

- Computer control system: programs the knitting patterns and monitors machine operation

- Drive system: powers the knitting carriage and other components

2. How do you diagnose and repair a knitting machine that is producing faulty fabric?

Troubleshooting steps

- Inspect the yarn and tension settings

- Check the knitting elements for damage or wear

- Examine the carriage for alignment and movement issues

- Review the computer program for errors or inconsistencies

- Calibrate the sensors and adjust the drive system as needed

Repair steps

- Replace damaged knitting elements

- Realign the knitting carriage

- Update or correct the computer program

- Adjust the drive system parameters

- Perform preventive maintenance tasks to minimize future issues

3. Describe the different types of yarn that can be used in knitting machines and their properties.

- Natural fibers: cotton, wool, silk, linen (soft, breathable, comfortable)

- Synthetic fibers: nylon, polyester, acrylic (durable, wrinkle-resistant, colorfast)

- Blended fibers: combinations of natural and synthetic fibers (balance properties)

- Specialty fibers: metallic, fiber optics, carbon fiber (add unique effects or features)

4. How do you maintain and calibrate a knitting machine to ensure optimal performance?

- Daily maintenance: clean and lubricate moving parts, check yarn tension

- Weekly maintenance: adjust knitting elements, recalibrate sensors

- Monthly maintenance: replace worn components, check carriage alignment

- Calibration: use precision instruments to ensure accurate stitch formation

- Follow manufacturer’s guidelines for specific maintenance and calibration procedures

5. Explain the safety protocols for working with knitting machines.

- Wear appropriate safety gear (gloves, safety glasses)

- Keep hair and loose clothing away from moving parts

- Operate machines in well-ventilated areas

- Follow machine lockout/tagout procedures before performing maintenance

- Report any safety concerns or incidents promptly

6. How do you ensure the quality of knitted fabrics and identify any defects?

- Visual inspection: check for evenness of stitches, correct pattern, absence of holes or snags

- Dimensional measurement: verify fabric dimensions meet specifications

- Fabric strength testing: assess fabric durability and tear resistance

- Colorfastness testing: ensure color retention after washing or exposure to light

- Identify and correct defects: reiKnit and repair faulty sections, adjust machine settings as needed

7. Describe the different types of knitting techniques and their applications.

- Plain knit: basic knit stitch creates a smooth, stretchy fabric

- Rib knit: alternating knit and purl stitches creates a ribbed texture

- Interlock knit: two parallel rows of knit stitches produce a strong, stable fabric

- Double knit: creates a two-layer fabric with a different appearance on each side

- Jacquard knit: uses multiple yarn colors to create complex patterns

8. How do you use computer-aided design (CAD) software to create knitting patterns?

- Import yarn and machine specifications

- Design stitch patterns using software tools

- Simulate knitting process to preview results

- Generate knitting instructions in machine-readable format

- Integrate CAD software with knitting machine control systems

9. What are the current trends and advancements in knitting machine technology?

- High-speed knitting machines: increased production efficiency

- Multi-feed knitting machines: knit multiple yarns simultaneously

- Digital knitting machines: enhanced pattern capabilities and flexibility

- Sustainable knitting practices: use of eco-friendly materials and processes

- 3D knitting technology: create complex shapes and structures

10. How do you stay updated with the latest developments in the knitting machine industry?

- Attend industry trade shows and conferences

- Read technical journals and articles

- Participate in online forums and webinars

- Network with other knitting professionals

- Train on new equipment and technologies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Knitting Machine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Knitting Machine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Knitting Machine Mechanics are responsible for the maintenance and repair of knitting machines. They work in a variety of settings, including textile mills, garment factories, and repair shops. Their primary responsibilities include:

1. Machine Maintenance

Knitting Machine Mechanics perform regular maintenance on knitting machines to keep them in good working condition. This includes tasks such as:

- Lubricating moving parts

- Adjusting tensions and settings

- Replacing worn or damaged parts

2. Troubleshooting and Repair

When knitting machines break down, Knitting Machine Mechanics diagnose the problem and make the necessary repairs. This may involve:

- Replacing faulty components

- Adjusting mechanical or electrical systems

- Troubleshooting computer-controlled knitting machines

3. Machine Installation and Setup

Knitting Machine Mechanics also install and set up new knitting machines. This involves:

- Assembling the machine

- Connecting the machine to power and other utilities

- Calibrating the machine and setting it up for production

4. Training and Supervision

Knitting Machine Mechanics may also be responsible for training and supervising other employees who operate knitting machines. This may involve:

- Providing instruction on how to operate the machines

- Supervising employees to ensure that they are following safety procedures

- Troubleshooting problems that employees may encounter

Interview Tips

To prepare for an interview for a Knitting Machine Mechanic position, you should:

1. Research the Company and the Position

Take some time to learn about the company you are applying to and the specific position you are interested in. This will help you to answer questions intelligently and demonstrate your interest in the opportunity.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work in the industry

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “What is your experience with knitting machines?”

- “How do you troubleshoot problems with knitting machines?”

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of the interview shows that you are interested in the position and that you have done your research. It also gives you an opportunity to learn more about the company and the position.

- “What are the biggest challenges facing the company right now?”

- “What are the company’s growth plans for the future?”

- “What is the company culture like?”

- “What are the opportunities for advancement within the company?”

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the opportunity.

- Wear a suit or business casual attire

- Be on time for your interview

- Be polite and respectful to the interviewer

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Knitting Machine Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.