Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Marine Erector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

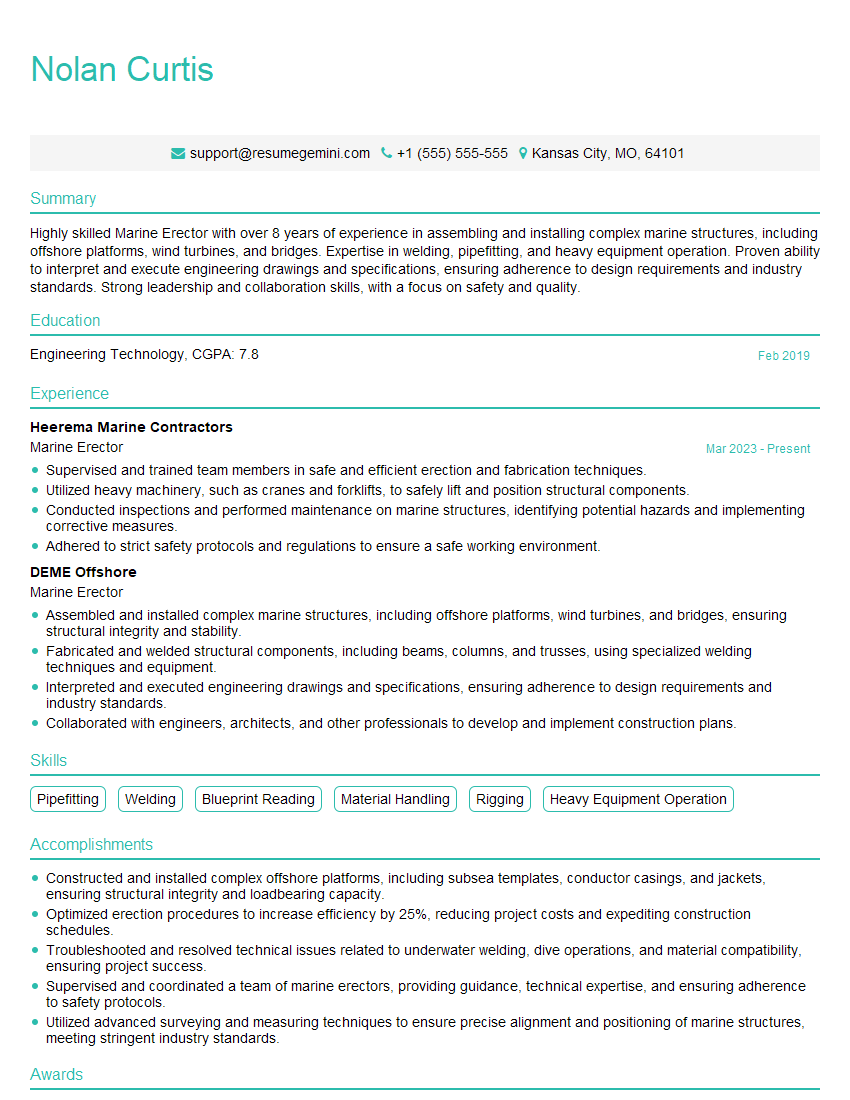

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Marine Erector

1. How would you erect a temporary scaffold on a ship?

To erect a temporary scaffold on a ship, I would follow these steps:

- Firstly, I will inspect the site and determine the type of scaffold required.

- Secondly, I will gather the necessary materials and equipment, including scaffolding frames, planks, and guardrails.

- Then, I will assemble the scaffold frame and secure it to the ship’s structure.

- Lastly, I will install the planks and guardrails to ensure a safe work platform.

2. How would you dismantle a scaffold?

Step 1: Safety First

- Ensure the work area is safe and clear of any hazards.

Step 2: Disassembling the Structure

- Remove the guardrails and toe boards.

- Carefully dismantle the scaffold frame.

- Bring down the scaffold planks and store them securely.

Step 3: Cleaning and Inspection

- Clean the scaffold components and inspect them for any damage.

3. What are the different types of welding processes and when would you use each of them?

There are several types of welding processes, each with its own advantages and applications. Here are some common types:

- Shielded Metal Arc Welding (SMAW): Also known as stick welding, it’s versatile and suitable for a wide range of materials. It’s commonly used in construction and repairs.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, it uses a continuous wire electrode and produces high-quality welds at faster speeds. It’s often used in automotive and manufacturing industries.

- Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, it uses a tungsten electrode and produces clean, high-precision welds. It’s ideal for intricate work and welding thin materials.

- Submerged Arc Welding (SAW): It uses a continuously fed electrode covered in flux, resulting in high productivity and deep penetration welds. It’s commonly used in heavy industries like shipbuilding and pipeline construction.

4. What are the safety precautions you should take when working with heavy machinery?

When working with heavy machinery, it’s crucial to prioritize safety. Here are some essential precautions:

- Proper Training: Ensure you’re adequately trained and certified to operate the machinery.

- Wear Protective Gear: Wear appropriate safety gear such as hard hats, safety glasses, and gloves.

- Inspect Equipment: Regularly inspect the machinery for any damage or malfunctions before operating it.

- Maintain a Safe Work Zone: Clear the work area of any hazards, debris, or unauthorized personnel.

- Follow Operating Procedures: Adhere to established operating procedures and avoid taking unnecessary risks.

5. How would you ensure the quality of your work?

Ensuring the quality of my work is paramount. Here’s how I approach it:

- Attention to Detail: I pay close attention to every aspect of my work, ensuring precision and accuracy.

- Following Standards: I adhere to industry standards and best practices to maintain high-quality results.

- Regular Inspections: I conduct regular inspections throughout the project to identify and address any potential issues promptly.

- Seeking Feedback: I welcome feedback from colleagues and supervisors to improve my work continuously.

- Continuous Learning: I stay updated with the latest techniques and technologies to enhance my skills and deliver exceptional results.

6. What do you consider to be the most challenging aspect of being a Marine Erector?

Working in a marine environment presents unique challenges for a Marine Erector. One of the most significant challenges is:

- Changing Conditions: Marine environments are subject to unpredictable weather and sea conditions, which can impact work schedules and require adaptability.

7. How do you stay up-to-date with the latest developments in the marine erection industry?

To stay current with the latest developments in the marine erection industry, I employ several strategies:

- Industry Publications: I subscribe to industry magazines and journals to stay informed about new techniques, technologies, and best practices.

- Conferences and Seminars: I attend industry conferences and seminars to learn from experts and network with other professionals.

- Online Resources: I utilize online platforms and forums to access up-to-date information and connect with industry professionals.

- Training Programs: I participate in training programs and workshops to enhance my skills and knowledge in specific areas.

8. What is your experience with planning and executing marine erection projects?

In my previous role as a Marine Erector, I was responsible for planning and executing various marine erection projects. My responsibilities included:

- Project Planning: I developed detailed project plans, including timelines, resource allocation, and safety protocols.

- Site Preparation: I prepared work sites by coordinating with other teams and ensuring the availability of necessary equipment and materials.

- Erection and Installation: I supervised and participated in the erection and installation of marine structures, ensuring adherence to design specifications and safety standards.

- Quality Control: I implemented quality control measures to ensure the structural integrity and functionality of the erected structures.

- Project Management: I managed project schedules, budgets, and resources effectively to deliver projects on time and within budget.

9. How do you ensure the safety of your team and the worksite during marine erection projects?

Ensuring the safety of my team and the worksite is my top priority durante marine erection projects. I implement the following measures:

- Safety Planning: I develop comprehensive safety plans that outline potential hazards and mitigation strategies.

- Hazard Identification: I conduct thorough risk assessments to identify potential hazards and implement control measures.

- Safety Training: I provide regular safety training to my team, covering topics such as proper equipment use, hazard recognition, and emergency procedures.

- Personal Protective Equipment (PPE): I ensure my team wears appropriate PPE, including hard hats, safety glasses, and life jackets.

- Emergency Preparedness: I establish clear emergency protocols and conduct regular drills to ensure my team is prepared to respond effectively to emergencies.

10. How do you communicate effectively with clients, colleagues, and supervisors during marine erection projects?

Effective communication is crucial in marine erection projects. I employ various strategies to foster clear and collaborative communication:

- Regular Meetings: I hold regular project meetings to provide updates, discuss progress, and address any challenges.

- Open Communication: I encourage open communication among team members and stakeholders, fostering a culture of transparency and feedback.

- Documentation: I maintain clear and accurate project documentation, including meeting minutes, progress reports, and technical drawings.

- Technology Utilization: I leverage technology, such as project management software and video conferencing, to facilitate efficient communication and collaboration.

- Active Listening: I prioritize active listening to understand the perspectives of others and ensure that all voices are heard.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Marine Erector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Marine Erector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Marine Erectors are responsible for constructing and assembling various structures and components in marine environments. Their key responsibilities include:

1. Structural Assembly

Erectors assemble and install structural components, such as beams, columns, and plates, following blueprints and specifications.

- Operate heavy machinery and equipment, such as cranes, hoists, and welding machines.

- Ensure proper alignment and fit of structural components.

2. Equipment Installation

They install and secure machinery, equipment, and piping systems on vessels, platforms, and other marine structures.

- Position and align equipment according to plans and specifications.

- Secure and connect equipment to ensure operational reliability.

3. Welding and Fabrication

Marine Erectors may perform welding and fabrication tasks to repair or modify structures and components.

- Follow welding procedures and standards to ensure weld quality and structural integrity.

- Use various welding techniques, such as arc welding, gas welding, and oxy-fuel welding.

4. Inspections and Maintenance

Erectors are involved in inspecting and maintaining structures and equipment to ensure safety and operational efficiency.

- Perform visual inspections, identify potential hazards, and recommend repairs or modifications.

- Conduct routine maintenance tasks, such as cleaning, lubrication, and adjustments.

Interview Tips

To ace a Marine Erector interview, it’s crucial to prepare and present yourself effectively.

1. Research the Company and Position

Thoroughly research the company, its industry, and the specific role you’re applying for. This demonstrates your interest and understanding of the position.

- Visit the company’s website, read industry news, and consult online forums.

- Identify the key requirements and responsibilities for the role.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that align with the job requirements. Quantify your accomplishments whenever possible.

- Showcase your expertise in structural assembly, equipment installation, welding, and inspections.

- Provide specific examples of projects where you successfully completed similar tasks.

3. Demonstrate Safety and Quality Consciousness

Marine Erector positions prioritize safety and quality. Demonstrate your commitment to these values.

- Discuss your adherence to safety protocols and regulations.

- Highlight your attention to detail and quality standards.

4. Prepare for Technical Questions

Expect technical questions about welding techniques, structural assembly procedures, and marine equipment installation.

- Review welding standards, such as AWS D1.1.

- Familiarize yourself with common marine equipment and installation techniques.

5. Practice Your Communication Skills

Effective communication is vital in Marine Erector jobs. Practice articulating your ideas clearly and confidently.

- Prepare to explain complex technical concepts in a concise manner.

- Be able to provide detailed descriptions of your work experience.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Marine Erector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.