Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Needle Straightener position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

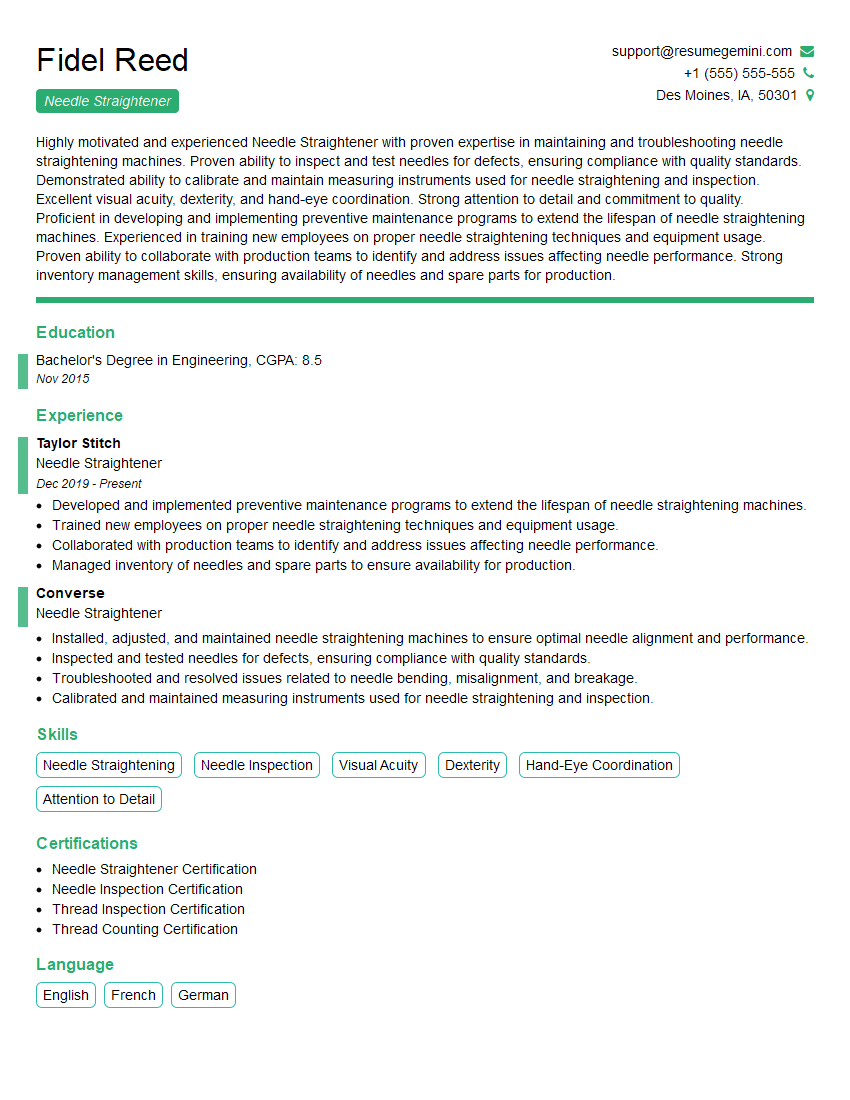

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Needle Straightener

1. What are the main types of needle straightening machines?

The two main types of needle straightening machines are:

- Rotary straightening machines: These machines use a rotating head with multiple straightening wheels to straighten needles.

- Linear straightening machines: These machines use a linear motion to straighten needles.

2. What are the key factors to consider when choosing a needle straightening machine?

The key factors to consider when choosing a needle straightening machine include:

- The type of needles to be straightened

- The desired straightening accuracy

- The production capacity required

- The available budget

3. How do you calibrate a needle straightening machine?

The calibration of a needle straightening machine involves:

- Setting the straightening wheels to the correct gap

- Adjusting the machine’s speed and pressure

- Running a series of test needles to ensure the machine is straightening needles to the desired accuracy

4. What are the common problems that can occur with needle straightening machines?

Common problems that can occur with needle straightening machines include:

- Broken needles

- Bent needles

- Misaligned needles

- Machine jams

5. How do you troubleshoot and resolve problems with needle straightening machines?

Troubleshooting and resolving problems with needle straightening machines involves:

- Identifying the source of the problem

- Taking corrective action to resolve the problem

- Testing the machine to ensure the problem has been resolved

6. What are the safety precautions that should be taken when operating a needle straightening machine?

The safety precautions that should be taken when operating a needle straightening machine include:

- Wearing appropriate safety gear (e.g., gloves, eye protection)

- Keeping hands and other body parts away from moving parts

- Not operating the machine if it is not properly calibrated or maintained

7. What are the different types of needles that can be straightened using a needle straightening machine?

Needle straightening machines can be used to straighten a variety of needles, including:

- Sewing needles

- Embroidery needles

- Knitting needles

- Crochet needles

8. What are the benefits of using a needle straightening machine?

Using a needle straightening machine offers several benefits, such as:

- Improved needle life

- Reduced production costs

- Enhanced product quality

- Increased productivity

9. How do you maintain a needle straightening machine?

Regular maintenance is essential to ensure the optimal performance of a needle straightening machine. Maintenance tasks include:

- Cleaning the machine

- Lubricating moving parts

- Inspecting the machine for wear and tear

- Replacing worn parts

10. What are the latest advancements in needle straightening technology?

The needle straightening industry is constantly evolving. Some of the latest advancements include:

- Automated needle straightening machines

- Higher-precision straightening wheels

- Computer-controlled straightening processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Needle Straightener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Needle Straightener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Needle Straightener is responsible for operating and maintaining machinery that straightens needles used in textile manufacturing. Their primary tasks include:

1. Needle Straightening

Operate needle straightening machines to straighten needles and ensure they meet specified dimensions and tolerances.

- Feed needles into the machine and monitor the straightening process.

- Adjust machine settings to optimize needle quality and productivity.

2. Quality Control

Perform quality control checks on straightened needles to ensure they meet quality standards.

- Inspect needles for defects, such as bends, burrs, or breaks.

- Sort needles and identify those that do not meet specifications.

3. Machine Maintenance

Conduct regular maintenance and inspection of needle straightening machines.

- Lubricate and clean machines to ensure smooth operation.

- Identify and troubleshoot machine problems and perform repairs as needed.

4. Production Monitoring

Monitor production rates and ensure that machines are operating efficiently.

- Track production targets and identify any deviations from plan.

- Report production data and any issues to supervisors.

Interview Tips

To ace an interview for a Needle Straightener position, it is crucial to prepare thoroughly. Here are some tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. Understanding the company’s needs will help you tailor your answers to their specific requirements.

- Visit the company’s website and social media pages.

- Research the textile manufacturing industry and its current challenges.

2. Highlight Relevant Experience

Emphasize your experience in needle straightening or related fields. Focus on transferable skills that align with the job responsibilities.

- Quantify your accomplishments and provide specific examples of how you have contributed to production.

- Highlight your ability to maintain and troubleshoot machinery.

3. Demonstrate Attention to Detail

As a Needle Straightener, attention to detail is paramount. Show the interviewer that you are meticulous and thorough in your work.

- Explain how you ensure that needles meet precise specifications.

- Describe your quality control procedures and how you minimize defects.

4. Express Interest in the Company

Convey your interest in the company and the Needle Straightener position. Explain how your skills and experience can contribute to their success.

- Share why you are drawn to the company’s mission or products.

- Explain how your goals align with the company’s objectives.

Next Step:

Now that you’re armed with the knowledge of Needle Straightener interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Needle Straightener positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini