Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Printing Mechanist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

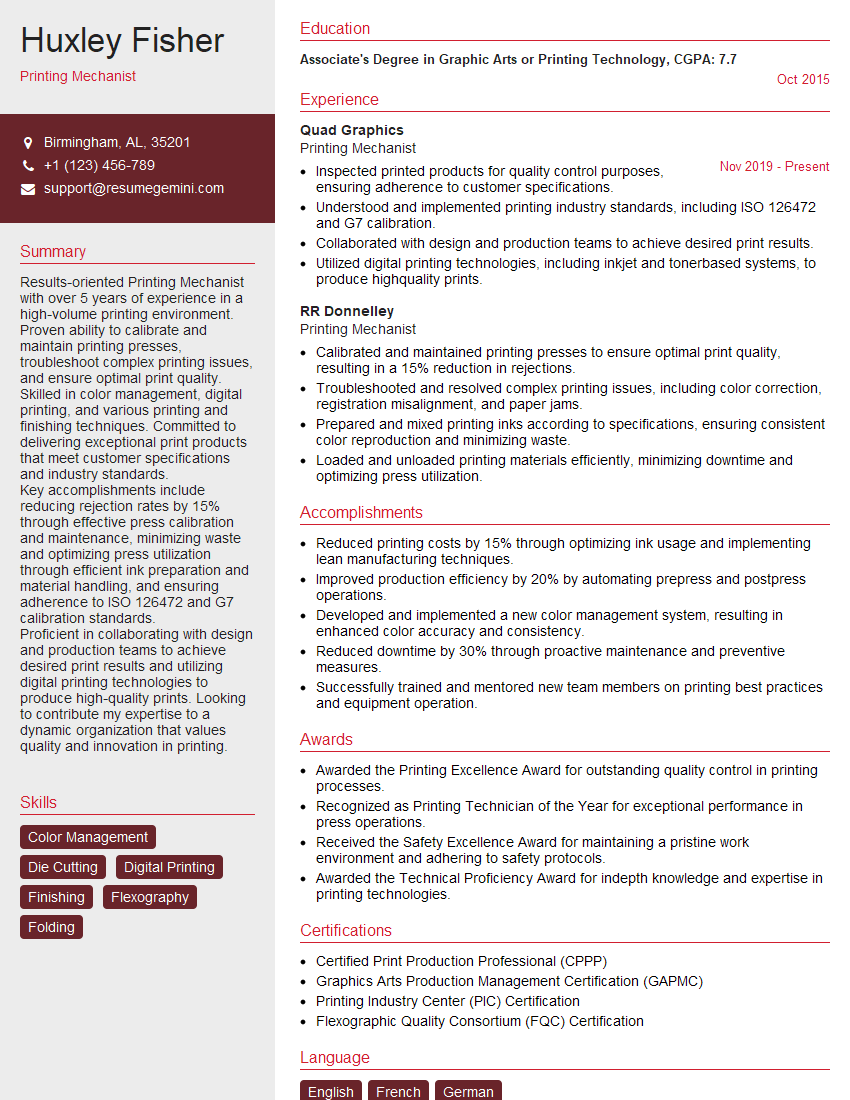

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Printing Mechanist

1. Explain the process of prepress color correction?

In prepress color correction, the colors of an image are adjusted to ensure that they will reproduce accurately when printed. This involves making adjustments to the hue, saturation, and lightness of the colors, as well as correcting for any color casts. The goal is to create a print-ready file that will produce an accurate representation of the original image.

2. Describe the different types of printing presses and their capabilities?

Offset Printing

- Uses a metal plate to transfer ink to paper.

- Capable of high-quality printing on a wide range of paper stocks.

Digital Printing

- Uses a computer-controlled printer to directly print to paper.

- Faster and more cost-effective for short runs.

Flexographic Printing

- Uses a flexible printing plate to transfer ink to plastic or foil.

- Used for printing on packaging and labels.

3. What are the different types of paper stocks and their applications?

There are many different types of paper stocks available, each with its own unique properties and applications. Some of the most common types of paper stocks include:

- Coated paper: Coated paper has a smooth, glossy surface that is ideal for printing high-quality images.

- Uncoated paper: Uncoated paper has a more natural, matte finish that is often used for printing text documents.

- Cardstock: Cardstock is a thick, durable paper that is often used for printing business cards, brochures, and other marketing materials.

4. How do you troubleshoot common printing problems, such as registration issues, color matching, and paper jams?

Common printing problems can include registration issues, color matching problems, and paper jams. To troubleshoot these problems, it is important to first identify the cause of the problem. Once the cause has been identified, you can then take steps to correct it.

- Registration issues: Registration issues occur when the different colors of an image are not aligned properly. This can be caused by a variety of factors, such as incorrect plate positioning or improper press settings.

- Color matching problems: Color matching problems occur when the colors of the printed image do not match the colors of the original image. This can be caused by a variety of factors, such as incorrect color calibration or improper ink mixing.

- Paper jams: Paper jams occur when paper becomes stuck in the printer. This can be caused by a variety of factors, such as improper paper loading or worn-out rollers.

5. What are the safety precautions that should be taken when working with printing equipment?

When working with printing equipment, it is important to take the following safety precautions:

- Always wear appropriate safety gear, such as gloves and safety glasses.

- Never put your hands or fingers near moving parts.

- Be aware of the location of the emergency stop button.

- Keep the work area clean and free of clutter.

- Follow all manufacturer’s instructions for the safe operation of the equipment.

6. What are the different types of printing inks and their applications?

There are many different types of printing inks available, each with its own unique properties and applications. Some of the most common types of printing inks include:

- Oil-based inks: Oil-based inks are made from a combination of pigments and oils. They are typically used for offset printing and flexographic printing.

- Water-based inks: Water-based inks are made from a combination of pigments and water. They are typically used for digital printing and inkjet printing.

- UV-curable inks: UV-curable inks are made from a combination of pigments and UV-curable resins. They are typically used for digital printing and inkjet printing.

7. How do you maintain and clean printing equipment?

To maintain and clean printing equipment, it is important to follow the manufacturer’s instructions. In general, printing equipment should be cleaned regularly to prevent the buildup of ink and debris. This can be done using a variety of cleaning supplies, such as brushes, rags, and cleaning solutions.

8. What are the different types of printing defects and how can they be prevented?

There are many different types of printing defects that can occur, such as streaking, banding, and ghosting. These defects can be caused by a variety of factors, such as improper ink mixing, incorrect press settings, or worn-out printing plates. To prevent printing defects, it is important to follow the manufacturer’s instructions for the proper operation of the printing equipment.

9. What are the latest trends in printing technology?

The printing industry is constantly evolving, with new technologies emerging all the time. Some of the latest trends in printing technology include:

- Digital printing: Digital printing is becoming increasingly popular due to its speed, affordability, and versatility.

- 3D printing: 3D printing is a new technology that allows for the creation of three-dimensional objects from digital files.

- Sustainable printing: Sustainable printing is becoming increasingly important as businesses look to reduce their environmental impact.

10. How do you stay up-to-date on the latest printing technologies and techniques?

To stay up-to-date on the latest printing technologies and techniques, it is important to read industry publications, attend trade shows, and participate in online forums. Additionally, it is important to take advantage of training opportunities offered by equipment manufacturers and suppliers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Printing Mechanist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Printing Mechanist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Printing Mechanist is responsible for the operation and maintenance of printing presses and other related equipment. They ensure that the printing process runs smoothly, efficiently, and produces high-quality printed materials.

1. Equipment Operation

Set up and operate printing presses, including adjusting paper feeders, ink rollers, and print settings.

- Monitor printing operations to ensure that the process is running smoothly and efficiently.

- Identify and resolve common printing problems, such as paper jams, ink smudges, and color misalignment.

2. Quality Control

Inspect printed materials to ensure they meet quality standards, such as color accuracy, sharpness, and registration.

- Make necessary adjustments to the printing process to correct any quality issues.

- Maintain accurate records of printing jobs, including materials used, press settings, and quality control checks.

3. Preventative Maintenance

Perform regular maintenance on printing equipment to prevent breakdowns and ensure optimal performance.

- Clean and lubricate moving parts, check for wear and tear, and replace worn components.

- Keep a maintenance log and report any potential problems to supervisors.

4. Troubleshooting and Repairs

Troubleshoot and repair minor printing equipment malfunctions, such as electrical problems, mechanical failures, and software issues.

- Work with other technicians or vendors to resolve complex equipment issues.

- Obtain necessary parts and materials to perform repairs.

Interview Tips

Interviewing for a Printing Mechanist position requires candidates to demonstrate their technical skills, knowledge of printing equipment and processes, and ability to work independently and as part of a team.

1. Research the Company and Role

Before the interview, thoroughly research the company and specific Printing Mechanist role you are applying for. This will help you understand the company’s values, the responsibilities of the position, and the qualities they are looking for in a candidate.

- Visit the company’s website, read industry news articles, and check social media platforms.

- Review the job description carefully and make note of the key qualifications and skills required.

2. Practice Common Interview Questions

In addition to questions about your skills and experience, there are several common interview questions that you are likely to be asked. Practice answering these questions concisely and effectively.

- Tell me about yourself and your qualifications for this position.

- What experience do you have with printing equipment and processes?

- How do you troubleshoot and resolve printing problems?

- What is your experience with preventative maintenance and repairs?

- Describe a time when you had to work independently and as part of a team to complete a task.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the position. Use specific examples to demonstrate your abilities.

- Quantify your accomplishments whenever possible, using specific numbers or metrics.

- Be enthusiastic and positive, and show that you are passionate about the printing industry.

4. Be Prepared to Ask Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is an opportunity for you to learn more about the company and the position, and to show your interest in the role.

- Ask thoughtful questions that demonstrate your interest in the company, the position, and the industry.

- Avoid asking questions that are too personal or that have already been answered during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Printing Mechanist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!