Feeling lost in a sea of interview questions? Landed that dream interview for Scale Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Scale Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

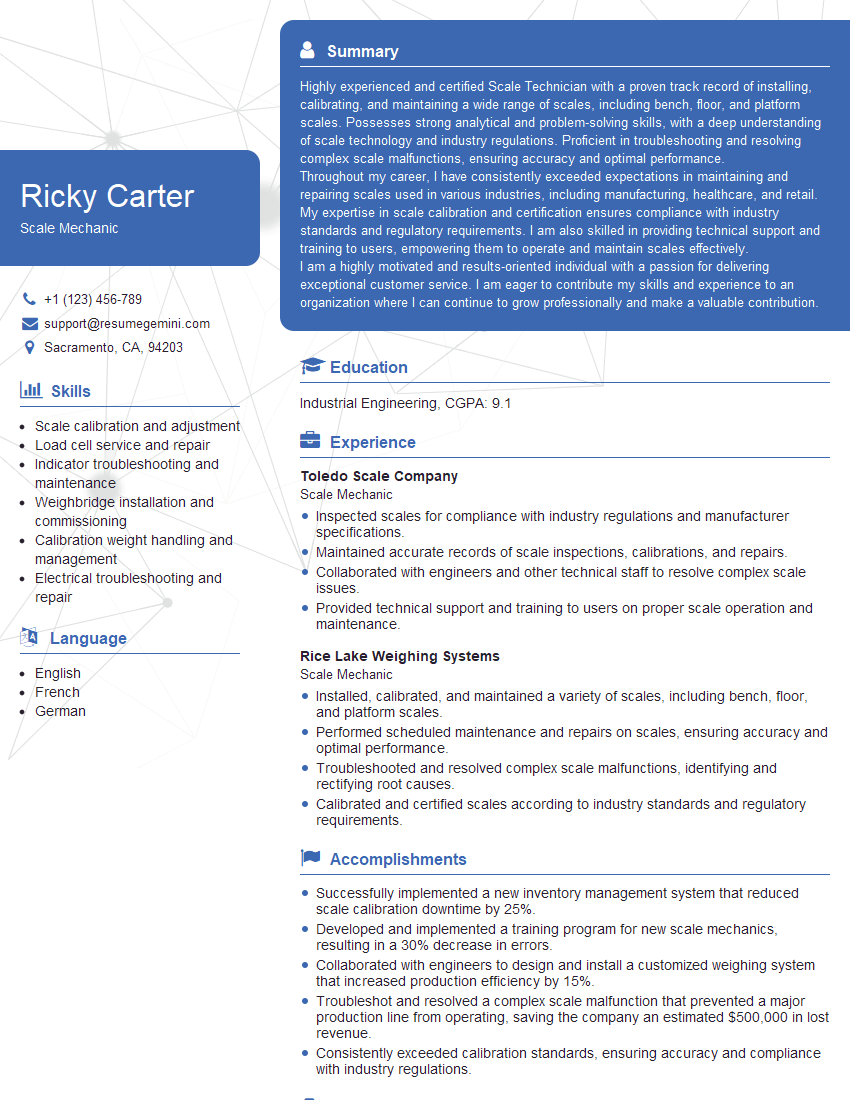

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Scale Mechanic

1. Describe the process of calibrating a weighing scale.

- Inspect the scale for any visible damage or loose parts.

- Place a known weight on the scale and check the reading.

- Adjust the scale’s calibration knob until the reading matches the known weight.

- Repeat steps 2 and 3 with different weights to ensure accurate calibration at multiple points.

- Document the calibration procedure and keep a record for future reference.

2. What are the different types of weighing scales, and when is it appropriate to use each type?

Mechanical scales

- Use a beam and weights to measure weight.

- Durable and reliable, but not as precise as electronic scales.

- Suitable for weighing large or heavy objects.

Electronic scales

- Use a load cell to convert weight into an electrical signal.

- More precise and versatile than mechanical scales.

- Available in various capacities and sizes for different applications.

Digital scales

- A type of electronic scale that displays the weight digitally.

- Easy to read and operate.

- Suitable for precise measurements in laboratory or industrial settings.

3. What are the common causes of weighing scale errors, and how can they be prevented?

- Incorrect calibration.

- Environmental factors (e.g., temperature fluctuations, vibrations).

- Improper installation or usage.

- Mechanical damage or wear and tear.

- To prevent errors, ensure regular calibration, protect the scale from environmental factors, use it correctly, and maintain it regularly.

4. What are the safety precautions that should be taken when working with weighing scales?

- Ensure the scale is properly calibrated and maintained.

- Avoid overloading the scale.

- Handle heavy objects safely to prevent injury.

- Follow manufacturer’s instructions for safe operation.

- Wear appropriate personal protective equipment (e.g., gloves) when handling hazardous materials.

5. How do you troubleshoot a weighing scale that is not functioning properly?

- Check the power supply and connections.

- Inspect the scale for any visible damage or loose parts.

- Recalibrate the scale using known weights.

- Check for environmental factors that may affect the scale’s accuracy.

- Consult the manufacturer’s manual for specific troubleshooting instructions.

6. What are the different materials used to make weighing scales, and what are the advantages and disadvantages of each material?

Stainless steel

- Advantages: Durable, corrosion-resistant, easy to clean.

- Disadvantages: More expensive than other materials.

Aluminum

- Advantages: Lightweight, corrosion-resistant, affordable.

- Disadvantages: Not as durable as stainless steel.

Plastic

- Advantages: Lightweight, inexpensive, portable.

- Disadvantages: Not as durable as other materials, can be affected by environmental factors.

7. What are the different types of weighing scale indicators, and what are their features and applications?

Analog indicators

- Features: Use a needle or pointer to indicate weight.

- Applications: Simple weighing tasks, where high precision is not required.

Digital indicators

- Features: Display weight digitally, with higher accuracy than analog indicators.

- Applications: Laboratory, industrial, and commercial settings where precise measurements are needed.

Remote indicators

- Features: Display weight remotely from the scale, via a cable or wireless connection.

- Applications: When the scale is located in a hazardous or inaccessible area.

8. What are the different types of load cells used in weighing scales, and how do they differ in terms of accuracy, capacity, and durability?

Strain gauge load cells

- Accuracy: High precision.

- Capacity: Range from small to large capacities.

- Durability: Durable and reliable.

Hydraulic load cells

- Accuracy: Moderate precision.

- Capacity: High capacity, suitable for heavy weighing tasks.

- Durability: Less durable than strain gauge load cells.

Pneumatic load cells

- Accuracy: Lower precision than other types.

- Capacity: High capacity, can handle extreme loads.

- Durability: Durable and resistant to harsh environments.

9. How do you maintain and inspect a weighing scale to ensure its accuracy and reliability?

- Regularly calibrate the scale using known weights.

- Inspect the scale for any visible damage or loose parts.

- Clean the scale according to the manufacturer’s instructions.

- Follow the manufacturer’s recommended maintenance schedule.

- Keep a log of maintenance and calibration activities for documentation purposes.

10. How do you handle and store weighing scales to prevent damage and ensure their longevity?

- Handle scales carefully to avoid shocks or impacts.

- Store scales in a dry, temperature-controlled environment.

- Use a carrying case or protective cover when transporting scales.

- Avoid exposing scales to extreme temperatures or moisture.

- Follow the manufacturer’s instructions for proper handling and storage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Scale Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Scale Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Scale Mechanics are responsible for installing, maintaining, and repairing industrial scales used in various industries. Their primary focus is ensuring the accuracy and reliability of these weighing systems.

1. Installation and Commissioning

Scale Mechanics are involved in the installation and commissioning of new scales. They ensure that the equipment is properly set up, aligned, and calibrated according to manufacturer specifications.

- Follow installation manuals and diagrams

- Connect electrical and mechanical components

- Perform initial calibration and testing

2. Maintenance and Inspection

Regular maintenance is crucial to ensure the optimal performance of scales. Scale Mechanics conduct routine inspections, clean and lubricate components, and replace worn parts as necessary.

- Inspect scales for wear, damage, or corrosion

- Clean and lubricate mechanical components

- Perform preventative maintenance checks

3. Calibration and Adjustment

Accurate weighing is essential for many industries. Scale Mechanics calibrate and adjust scales to meet specific accuracy requirements. They use specialized equipment and techniques to ensure precise measurements.

- Use calibration weights and test materials

- Adjust scales to meet accuracy tolerances

- Maintain calibration records

4. Troubleshooting and Repair

When scales malfunction or encounter problems, Scale Mechanics diagnose and repair the issues. They have a deep understanding of the mechanical and electrical components of scales and can identify and rectify faults.

- Troubleshoot electrical and mechanical problems

- Replace defective parts

- Perform repairs according to manufacturer guidelines

Interview Tips

Preparing thoroughly for a Scale Mechanic interview is crucial to showcase your skills and experience effectively. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Demonstrating knowledge of the company’s operations and the industry in which they operate shows you have a genuine interest in the role. Learn about the company’s products, services, and recent developments. Research industry trends and advancements to stay informed.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers. Practice your responses out loud to improve your delivery and confidence. Consider questions about your experience in scale installation, maintenance, calibration, and troubleshooting. Highlight your technical skills and problem-solving abilities.

3. Showcase Your Troubleshooting Abilities

Scale Mechanics are often required to troubleshoot and repair complex weighing systems. Prepare examples of how you have successfully diagnosed and resolved issues with scales. Emphasize your analytical thinking, problem-solving skills, and attention to detail.

4. Highlight Relevant Certifications and Experience

Possessing industry-recognized certifications and prior experience in scale maintenance and repair demonstrates your credibility as a Scale Mechanic. Mention any certifications or training programs you have completed, as well as any relevant work experience that showcases your skills in this field.

5. Ask Thoughtful Questions

Asking thoughtful questions during the interview not only shows your engagement but also allows you to gather more information about the role and company. Prepare questions that demonstrate your interest in the specific responsibilities of the position or the company’s future plans in the industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Scale Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.