Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Test Engine Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

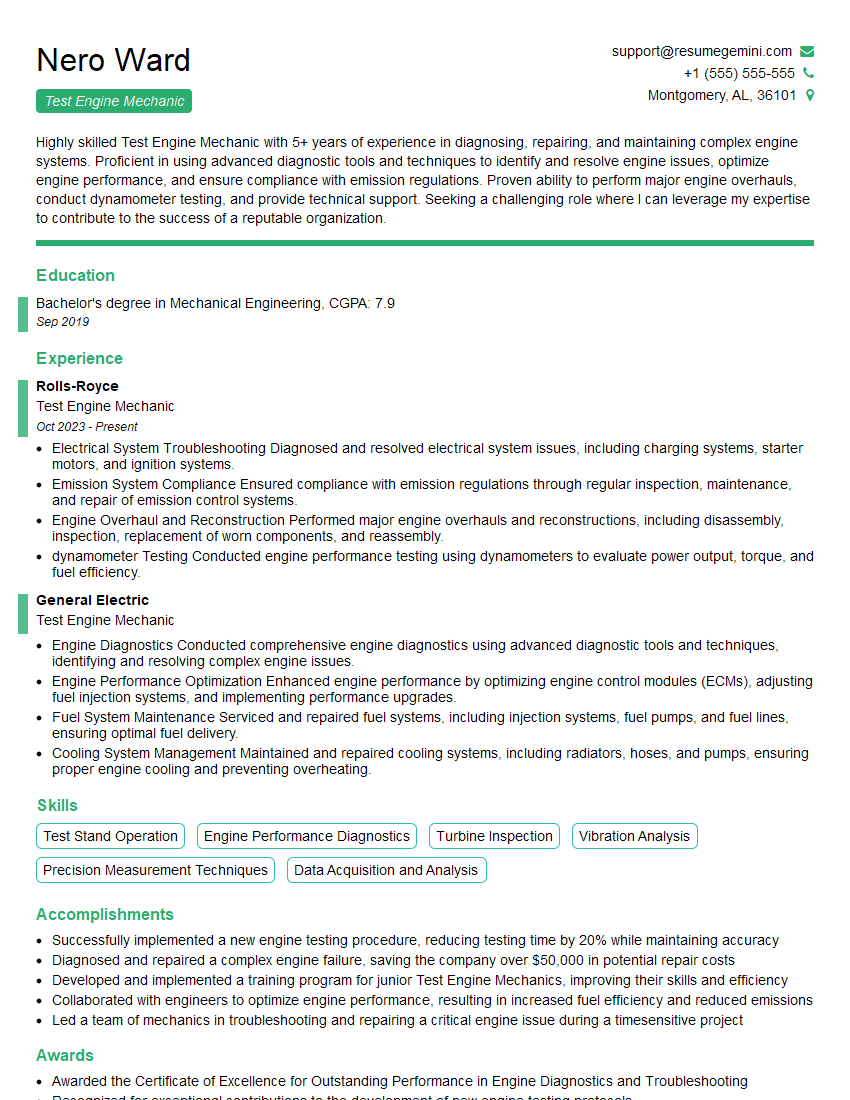

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Test Engine Mechanic

1. Describe the process involved in performing a compression test on a gasoline engine?

The process of performing a compression test on a gasoline engine involves the following steps:

- Remove all spark plugs.

- Insert a compression tester into one of the spark plug holes.

- Crank the engine over several times until the compression tester gauge reaches its maximum reading.

- Record the maximum reading.

- Repeat steps 2-4 for each of the remaining spark plug holes.

2. What are the typical compression ratios for gasoline and diesel engines?

Gasoline engines

- 8.5:1 to 12:1

Diesel engines

- 14:1 to 25:1

3. What are the common causes of low compression in an engine?

The common causes of low compression in an engine can be attributed to:

- Worn or damaged piston rings

- Leaking valves

- Damaged cylinder head gasket

- Carbon buildup

4. What are the symptoms of a blown head gasket?

The symptoms of a blown head gasket can include:

- White smoke from the exhaust

- Loss of coolant

- Overheating

- Rough idle

- Poor performance

5. What are the different types of engine oils and their applications?

The different types of engine oils and their applications include:

- Mineral oil: Suitable for older vehicles and engines operating in less demanding conditions.

- Synthetic oil: Provides better protection and performance, suitable for newer vehicles and engines operating in extreme conditions.

- Semi-synthetic oil: A blend of mineral and synthetic oils, offering a balance of performance and cost.

6. What are the recommended maintenance intervals for spark plugs and air filters?

The recommended maintenance intervals for spark plugs and air filters vary depending on the make and model of the vehicle. However, general guidelines include:

- Spark plugs: Every 30,000 to 60,000 miles

- Air filters: Every 12,000 to 15,000 miles or as needed based on driving conditions.

7. How do you diagnose and repair a faulty fuel injector?

Diagnosing and repairing a faulty fuel injector involves:

- Using a fuel pressure gauge to check fuel pressure.

- Checking the electrical resistance of the injector.

- Listening for a clicking sound when the injector is activated.

- Replacing the injector if it is found to be faulty.

8. What are the common causes of engine overheating?

The common causes of engine overheating include:

- Low coolant levels

- Faulty thermostat

- Clogged radiator

- Water pump failure

- Head gasket failure

9. Describe the function of an oxygen sensor in an engine management system?

An oxygen sensor in an engine management system serves the following functions:

- Measures the amount of oxygen in the exhaust gases.

- Provides feedback to the engine control module (ECM).

- The ECM uses this feedback to adjust the air-fuel ratio to maintain optimal combustion.

10. How do you perform a valve adjustment on an overhead cam engine?

Performing a valve adjustment on an overhead cam engine involves:

- Removing the valve cover.

- Using a feeler gauge to measure the valve clearance.

- Adjusting the clearance using an adjusting screw or shim.

- Re-installing the valve cover.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Test Engine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Test Engine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Test Engine Mechanics are responsible for maintaining and repairing aircraft engines, ensuring their safe and efficient operation.

1. Maintenance and Repair

Conduct scheduled and unscheduled maintenance and repairs on aircraft engines, including troubleshooting issues, replacing or repairing components, and performing inspections and adjustments.

- Read and interpret technical manuals and schematics to understand engine systems and operations.

- Utilize specialized tools and equipment to diagnose and resolve engine problems.

2. Inspections and Testing

Perform inspections and tests on aircraft engines to ensure they meet safety standards and operational requirements.

- Conduct visual inspections to detect defects or signs of wear and tear.

- Operate engine test rigs to monitor performance and diagnose any malfunctions.

3. Documentation and Record Keeping

Maintain accurate records of engine maintenance and repairs, including work performed, parts replaced, and inspections conducted.

- Complete maintenance logs and other relevant documentation.

- Report any discrepancies or non-conformances to supervisors or regulatory authorities.

4. Safety and Compliance

Adhere to safety protocols and industry regulations, ensuring that engine maintenance and repairs are performed in a safe and compliant manner.

- Wear appropriate safety gear and follow established procedures.

- Stay abreast of industry regulations and safety guidelines.

Interview Tips

Preparing for your interview as a Test Engine Mechanic is crucial to making a positive impression. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the company and the aviation industry. This demonstrates your interest in the position and shows that you’ve made an effort to learn about the company’s operations and culture.

- Visit the company website and read about their mission, values, and services.

- Read industry publications and news articles to stay informed about current trends and technologies.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers in advance. This will help you feel more confident and organized during the interview.

- Prepare answers to questions about your technical skills, experience, and qualifications.

- Practice answering questions about your problem-solving abilities and attention to detail.

3. Highlight Your Skills and Experience

Tailor your resume and cover letter to the specific requirements of the Test Engine Mechanic position. Emphasize your relevant skills and experience, such as:

- Proficiency in aircraft engine maintenance and repair.

- Experience using specialized tools and equipment.

- Strong understanding of engine systems and operations.

4. Prepare Technical Questions

In addition to answering interview questions, consider preparing technical questions to ask the interviewer. This shows that you’re engaged in the conversation and interested in learning more about the position and company.

- Ask about the company’s safety protocols and quality standards.

- Inquire about the types of aircraft engines they maintain and the latest technologies they use.

5. Follow Up After the Interview

After the interview, send a thank-you note to the interviewer reiterating your interest in the position and highlighting your key qualifications. This shows your appreciation for their time and consideration.

- Restate your main skills and experience that align with the job requirements.

- Express your enthusiasm for the opportunity and your willingness to contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Test Engine Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.