Feeling lost in a sea of interview questions? Landed that dream interview for Tool and Fixture Repairer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tool and Fixture Repairer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

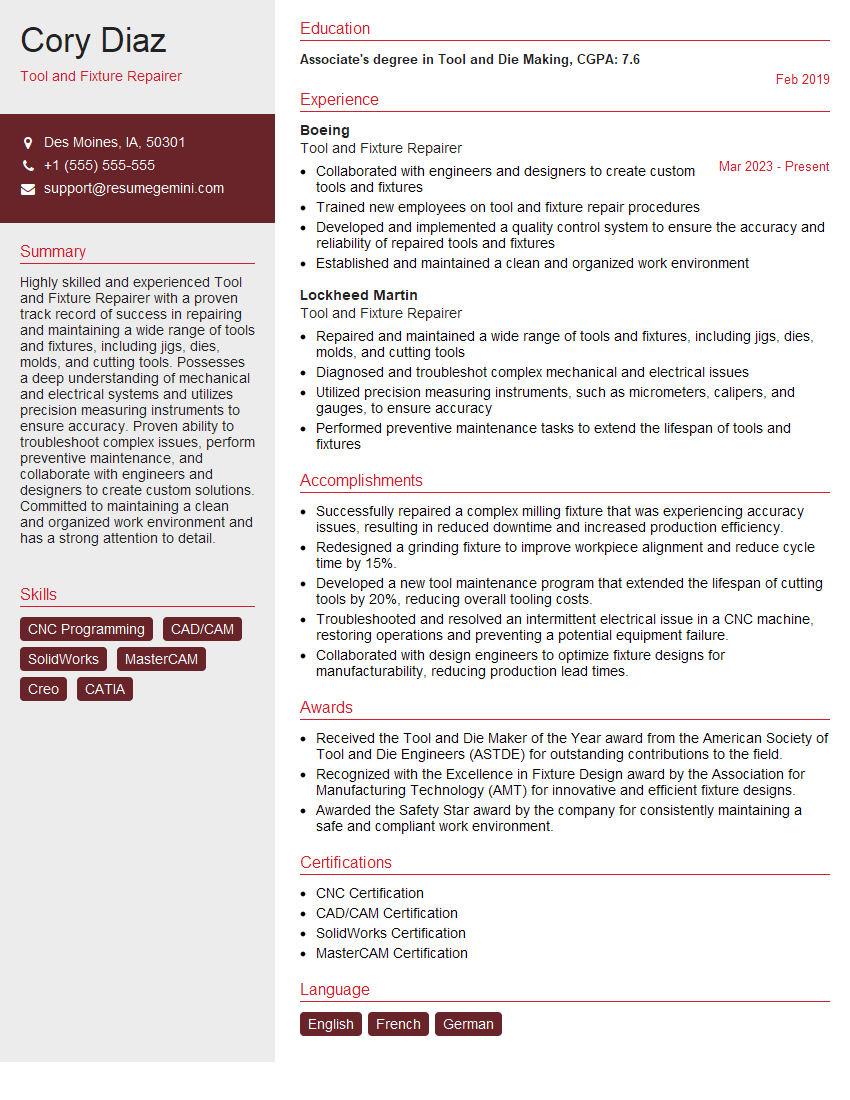

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool and Fixture Repairer

1. What are the primary responsibilities of a Tool and Fixture Repairer?

The primary responsibilities of a Tool and Fixture Repairer include:

- Diagnosing and repairing faulty tools and fixtures used in production processes.

- Inspecting tools and fixtures for wear and tear, and identifying potential problems.

- Overhauling and rebuilding tools and fixtures to ensure optimal performance.

- Maintaining accurate records of repairs and maintenance activities.

- Providing technical support to production staff and assisting with troubleshooting.

2. What are the key skills and qualifications required for a Tool and Fixture Repairer?

Technical Skills

- Extensive knowledge of tool and fixture design and construction.

- Strong mechanical aptitude and ability to diagnose and repair complex problems.

- Proficiency in using precision measuring instruments, such as micrometers and calipers.

- Experience with welding, machining, and other metalworking techniques.

Qualifications

- High school diploma or equivalent preferred.

- Certifications in tool and fixture repair or related fields are desirable.

- Minimum of 3-5 years of experience in a similar role.

3. What are the different types of tools and fixtures that you have experience repairing?

I have experience repairing a wide variety of tools and fixtures, including:

- Cutting tools, such as drills, milling cutters, and end mills.

- Gauges and measuring instruments.

- Hydraulic and pneumatic cylinders.

- Conveyor systems.

- Welding fixtures.

4. What is your process for diagnosing and repairing a faulty tool or fixture?

My process for diagnosing and repairing a faulty tool or fixture involves the following steps:

- Inspecting the tool or fixture for obvious damage or wear.

- Reviewing the tool or fixture’s specifications and documentation.

- Conducting performance tests to identify the source of the problem.

- Disassembling the tool or fixture to inspect its internal components.

- Diagnosing the problem and determining the appropriate repairs.

- Repairing the tool or fixture using appropriate techniques and materials.

- Reassembling the tool or fixture and conducting final performance tests.

5. What are some of the common problems that you encounter when repairing tools and fixtures?

Some of the common problems that I encounter when repairing tools and fixtures include:

- Worn or damaged cutting edges.

- Misaligned components.

- Leaking hydraulic or pneumatic cylinders.

- Damaged electrical components.

- Excessive vibration or noise.

6. What is the most challenging repair that you have ever performed?

The most challenging repair that I have ever performed was repairing a large welding fixture that had been damaged in a collision. The fixture was very complex and had multiple components that needed to be precisely aligned. I had to use a variety of techniques, including welding, machining, and alignment, to complete the repair. The fixture was successfully repaired and returned to production.

7. What are the safety precautions that you take when repairing tools and fixtures?

Safety is my top priority when repairing tools and fixtures. I always follow these precautions:

- Wearing appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Ensuring that the work area is well-lit and free of hazards.

- Using tools and equipment properly and in accordance with manufacturer’s instructions.

- Never attempting to repair a tool or fixture that is beyond my capabilities.

- Reporting any unsafe conditions or practices to my supervisor immediately.

8. What are your goals for this position?

My goals for this position are to:

- Use my skills and experience to keep the company’s tools and fixtures in optimal condition.

- Reduce downtime and improve production efficiency.

- Contribute to the company’s overall success.

9. What is your availability?

I am available to work flexible hours, including weekends and overtime, if necessary. I am also willing to travel for work.

10. Do you have any questions for me?

I do not have any questions at this time. Thank you for your time and consideration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool and Fixture Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool and Fixture Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool and Fixture Repairers are responsible for maintaining and repairing tools, fixtures, and other equipment used in manufacturing and production facilities. Their primary duties include:

1. Inspecting and Diagnosing

Inspecting and diagnosing tools and fixtures to identify any issues, defects, or malfunctions.

- Identifying the root cause of problems and recommending solutions.

- Conducting regular maintenance checks and calibrations to ensure optimal performance.

2. Repairing and Overhauling

Repairing and overhauling tools and fixtures by replacing damaged parts, adjusting components, and performing necessary modifications.

- Using specialized tools and techniques to disassemble and reassemble equipment.

- Working with engineers and designers to develop and implement improvements to tools and fixtures.

3. Modifying and Fabricating

Modifying and fabricating new tools and fixtures as per specific requirements.

- Creating custom solutions to meet unique production needs.

- Collaborating with other departments to design and develop specialized tooling.

4. Troubleshooting and Training

Troubleshooting production issues related to tools and fixtures.

- Providing training to operators and maintenance personnel on proper use and maintenance of tools.

- Documenting repair procedures and maintaining records of completed work.

Interview Tips

Preparing for an interview for a Tool and Fixture Repairer position requires thorough research and a well-crafted strategy. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company’s website, industry news, and social media profiles to understand their business, culture, and the specific requirements of the role.

- Identify key responsibilities and skills that match your qualifications.

- Prepare specific examples of your experience that demonstrate your abilities.

2. Practice Your Answers

Practice answering common interview questions related to your skills, experience, and motivation.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide context.

- Use industry-specific terminology and technical jargon to showcase your knowledge.

3. Highlight Your Problem-Solving Skills

Emphasize your ability to identify and solve problems related to tools and fixtures.

- Provide examples of how you have diagnosed and repaired complex issues in the past.

- Explain your troubleshooting process and how you prioritize repairs to minimize downtime.

4. Showcase Your Knowledge of Tools and Equipment

Demonstrate your familiarity with various types of tools, fixtures, and manufacturing equipment.

- List your experience with different types of machinery, hand tools, and measuring devices.

- Highlight your understanding of preventive maintenance and calibration procedures.

5. Present Your Commitment to Safety and Quality

Emphasize your commitment to maintaining a safe and efficient work environment.

- Explain how you follow safety protocols and use proper protective gear.

- Describe your quality control measures and how you ensure that repaired tools and fixtures meet specifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool and Fixture Repairer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.