Are you gearing up for a career in Tipple Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tipple Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

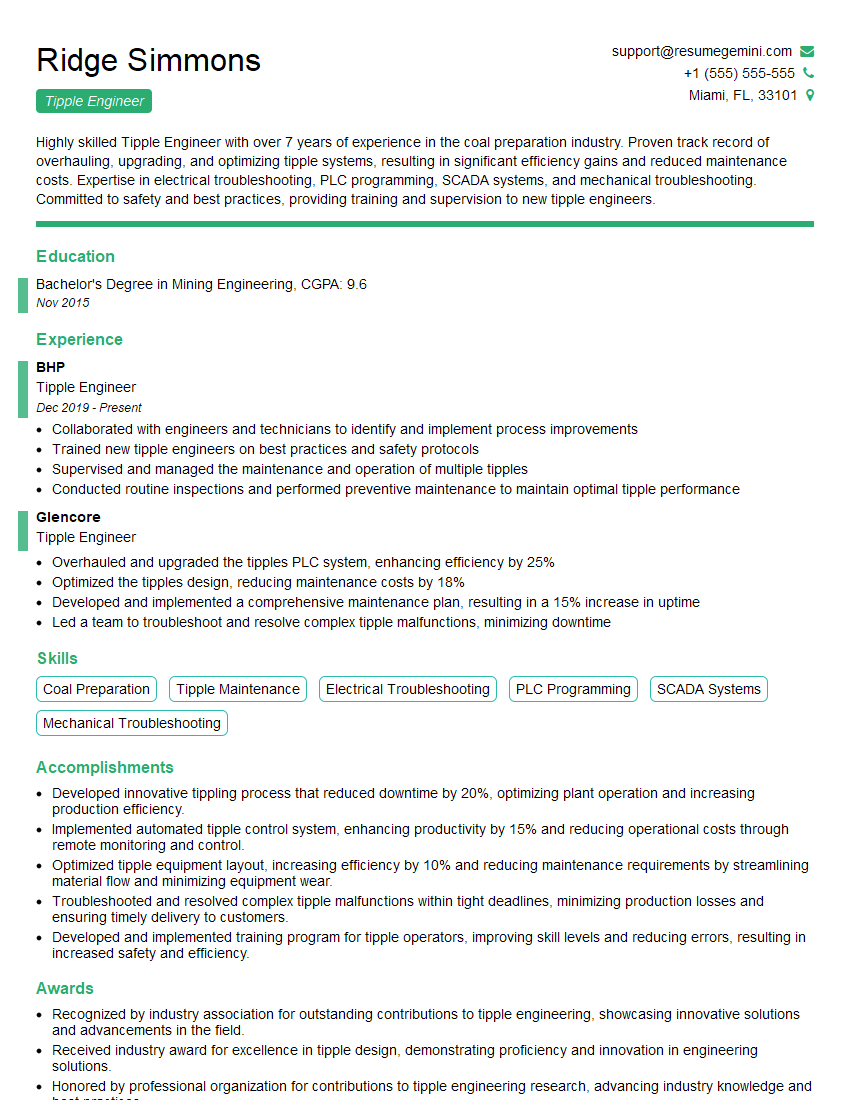

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tipple Engineer

1. What operating procedures are followed to facilitate the flow of the product from the train/truck dumper through the tipple and the preparation plant?

- Monitor and ensure proper operation of the train/truck dumper.

- Control and adjust feed rates to match the capacity of the preparation plant.

- Identify and resolve operational issues that may impede product flow.

- Collaborate with the preparation plant personnel to optimize the overall process efficiency.

2. How do you ensure that the tipple equipment is operating efficiently and reliably to minimize downtime?

Maintenance and Inspection

- Perform regular inspections and preventive maintenance on all equipment.

- Identify potential issues early on and address them proactively.

- Collaborate with maintenance personnel to ensure timely repairs and replacements.

Operator Training

- Provide comprehensive training to operators on proper equipment operation.

- Establish clear operating procedures and guidelines.

- Monitor and evaluate operator performance to identify areas for improvement.

Process Optimization

- Analyze and optimize the tipple process to reduce downtime and improve efficiency.

- Implement automation and technology to enhance equipment reliability.

- Monitor key performance indicators and make data-driven decisions to continuously improve the operation.

3. How do you troubleshoot and resolve operational issues in the tipple such as equipment breakdowns, product flow interruptions, or quality concerns?

- Quickly identify the root cause of the issue through systematic troubleshooting.

- Develop and implement effective solutions to resolve the problem efficiently.

- Communicate clearly with maintenance and other personnel to coordinate repairs or adjustments.

- Document and analyze operational issues to identify patterns and develop preventive measures.

4. How do you ensure the safety of personnel and equipment during tipple operations?

- Adhere to all established safety protocols and procedures.

- Conduct regular safety inspections to identify and mitigate potential hazards.

- Train operators on proper safety practices and emergency procedures.

- Monitor and enforce the use of personal protective equipment (PPE).

- Stay informed about changes in safety regulations and best practices.

5. How do you coordinate with other departments such as the preparation plant, maintenance, and quality control to ensure seamless operation of the tipple?

- Establish clear communication channels and protocols.

- Attend regular coordination meetings to discuss operational goals and challenges.

- Provide timely updates on tipple performance and any potential issues.

- Collaborate on process optimization projects to improve overall plant efficiency.

- Seek feedback and input from other departments to continuously improve the tipple operation.

6. How do you prioritize and manage multiple tasks and responsibilities as a Tipple Engineer?

- Develop a clear understanding of priorities and deadlines.

- Use effective time management techniques to allocate time wisely.

- Delegate tasks to other team members when appropriate.

- Stay organized and maintain a systematic approach to workflow.

- Communicate progress and any challenges to stakeholders regularly.

7. What industry best practices and technological advancements have you implemented to improve the efficiency and effectiveness of the tipple operation?

- Automation and remote monitoring systems to enhance equipment reliability and reduce downtime.

- Data analytics and process optimization to identify bottlenecks and improve flow rates.

- Advanced sensors and control systems to ensure product quality and consistency.

- Collaboration with equipment manufacturers and industry experts to stay abreast of latest technologies.

- Implementation of lean principles and continuous improvement methodologies.

8. How do you stay updated on the latest industry trends, standards, and regulations related to tipple operations?

- Attend industry conferences and workshops.

- Read technical journals and industry publications.

- Participate in professional organizations and networking events.

- Collaborate with experts and thought leaders in the field.

- Stay informed about changes in government regulations and environmental policies.

9. How do you measure and evaluate the performance of the tipple operation?

- Establish key performance indicators (KPIs) such as throughput, downtime, and product quality.

- Collect and analyze data using monitoring systems and reports.

- Benchmark performance against industry standards and best practices.

- Identify areas for improvement and develop action plans to enhance tipple efficiency.

- Regularly review and adjust performance metrics to ensure alignment with operational goals.

10. How do you manage and address environmental concerns related to tipple operations, such as dust control and water management?

- Implement effective dust control measures using dust collectors and water sprays.

- Design and maintain water management systems to control runoff and prevent pollution.

- Monitor and comply with environmental regulations and standards.

- Collaborate with environmental agencies and stakeholders to address concerns and ensure sustainability.

- Continuously evaluate and improve environmental practices to minimize the impact of tipple operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tipple Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tipple Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tipple Engineers are responsible for the design, installation, and maintenance of coal processing systems. Their duties may include:

1. Design and Engineering

Designing and developing new coal processing systems and modifications to existing systems.

- Conducting feasibility studies and developing conceptual designs.

- Preparing detailed engineering drawings and specifications.

2. Equipment Selection and Procurement

Selecting and procuring equipment for coal processing systems, including crushers, screens, conveyors, and other machinery.

- Evaluating vendor proposals and conducting site visits.

- Negotiating contracts and managing procurement processes.

3. Installation and Commissioning

Providing technical support during the installation and commissioning of coal processing systems.

- Supervising the installation and commissioning process.

- Troubleshooting and resolving any technical issues.

4. Maintenance and Troubleshooting

Maintaining and troubleshooting coal processing systems to ensure optimal performance.

- Performing routine inspections and maintenance tasks.

- Troubleshooting and repairing system malfunctions.

Interview Tips

Here are some interview tips and preparation hacks to help candidates ace their interview for a Tipple Engineer position:

1. Research the Industry and Company

Demonstrate your knowledge of the coal processing industry and the specific company you are interviewing with. Research their website, annual reports, and any recent news articles to gain insights into their business operations and values.

- Familiarize yourself with current industry trends and best practices.

- Show that you understand the company’s products, services, and mission.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview answers to emphasize the skills and experience that are most relevant to the Tipple Engineer position. Quantify your accomplishments and provide specific examples of your work in coal processing.

- Showcase your proficiency in design software and engineering principles.

- Highlight your experience in equipment selection, installation, and troubleshooting.

3. Practice Common Interview Questions

Anticipate and prepare for common interview questions related to your qualifications, experience, and the Tipple Engineer role. Practice your answers and deliver them with confidence and clarity.

- Prepare answers to questions about your technical skills and knowledge.

- Be ready to discuss your project management and leadership abilities.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions that show your understanding of the role, the company, and the industry.

- Inquire about the company’s goals and challenges for the Tipple Engineer position.

- Ask about the company’s commitment to innovation and technology.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tipple Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.