Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool Mechanic so you can tailor your answers to impress potential employers.

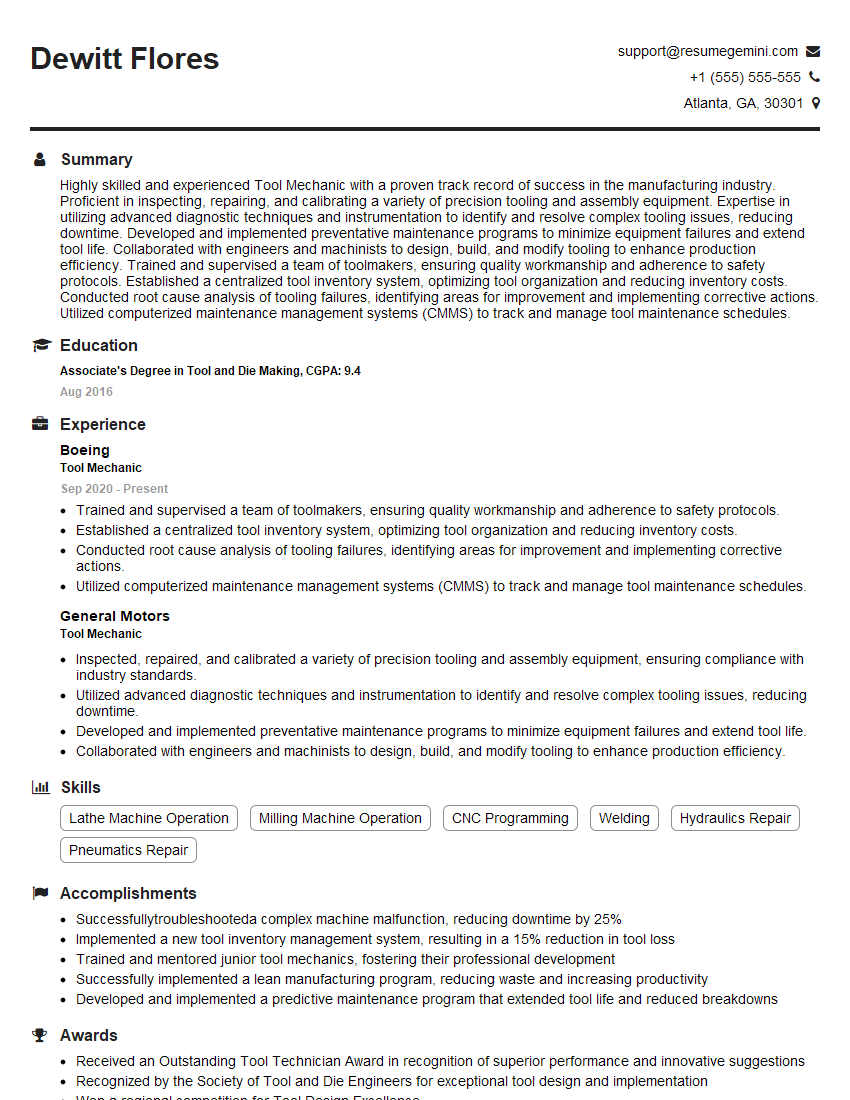

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Mechanic

1. How do you ensure that the tools are maintained and calibrated correctly?

As a Tool Mechanic, I follow a comprehensive maintenance and calibration program to ensure the accuracy and functionality of all tools.

- Regular Inspections and Maintenance: I conduct routine inspections to identify any signs of wear or damage, and perform necessary maintenance tasks such as cleaning, lubrication, and adjustments.

- Calibration Checks: Using certified calibration equipment, I regularly check and adjust the precision and accuracy of measuring tools, such as micrometers, calipers, and gauges, to meet industry standards and specifications.

- Record Keeping: I maintain detailed records of all maintenance and calibration activities, including dates, findings, and corrective actions, for traceability and audit purposes.

2. Describe the process of repairing a hydraulic cylinder.

Troubleshooting and Inspection

- Inspect the cylinder for signs of leaks, damage, or abnormal noises.

- Test the cylinder’s performance using hydraulic pressure to identify any issues.

- Disassemble the cylinder and examine its components, including the piston, seals, and valve.

Repair and Replacement

- Replace damaged or worn components, such as seals, O-rings, or the piston.

- Resurface or bore the cylinder to smooth out imperfections and maintain proper tolerances.

- Reassemble the cylinder and conduct pressure tests to verify its functionality.

Testing and Validation

- Perform operational tests under load to ensure the repaired cylinder meets specifications.

- Document the repair process and test results for future reference.

3. How do you troubleshoot and repair electrical faults in machinery?

Electrical troubleshooting involves a systematic approach to identify and resolve faults in machinery.

- Visual Inspection: Inspect wiring, connections, and components for any obvious damage or loose connections.

- Electrical Testing: Use a multimeter or other testing equipment to measure voltage, current, and resistance at key points in the circuit.

- Component Testing: Isolate and test individual components, such as switches, relays, and sensors, to determine their functionality.

- Circuit Analysis: Analyze the electrical circuit diagram to understand the flow of power and identify potential sources of faults.

- Repair and Replacement: Replace faulty components, repair damaged wiring, or adjust settings as necessary to restore proper operation.

4. What are the different types of metalworking fluids and their uses?

Metalworking fluids play a crucial role in various machining processes.

- Cutting Fluids: Used to cool the cutting tool and workpiece, reduce friction, and improve tool life. They include soluble oils, semi-synthetics, and synthetic fluids.

- Grinding Fluids: Specifically formulated for grinding operations to remove heat, prevent rust, and provide lubrication. They can be water-based, oil-based, or synthetic.

- Tapping and Threading Fluids: Designed to improve surface finish, reduce friction during tapping and threading processes. They help prevent tool breakage and workpiece damage.

- Forming Fluids: Used in cold forming and stamping operations to reduce friction and prevent galling. They can be oil-based, grease-based, or wax-based.

- Cleaning Fluids: Used to remove metal chips, dirt, and debris from tools and workpieces. They can be water-based or solvent-based.

5. How do you ensure workplace safety while working with machinery and tools?

Workplace safety is paramount in a Tool Mechanic’s role.

- Proper Training: Undergo comprehensive training on all machinery and tools, including their safe operation and maintenance procedures.

- Personal Protective Equipment: Wear appropriate PPE, such as safety glasses, gloves, and protective clothing, to minimize risks of injury.

- Machine Guards: Ensure that all machinery has proper guards and safety features in place to protect against moving parts or flying debris.

- Lockout/Tagout Procedures: Follow established lockout/tagout procedures when performing maintenance or repairs to prevent accidental operation.

- Hazard Assessment: Regularly assess the workplace for potential hazards and implement measures to eliminate or minimize risks.

6. Describe your experience with using CNC machines.

- Proficient in programming, setting up, and operating CNC mills, lathes, and machining centers.

- Experience in developing and troubleshooting CNC programs using various software platforms.

- Expertise in selecting and using appropriate cutting tools and workholding fixtures for CNC machining.

- Thorough understanding of CNC machine controls, parameters, and error diagnostics.

- Ability to optimize CNC machining processes for efficiency, accuracy, and surface quality.

7. What are the key factors to consider when selecting cutting tools?

- Material of the workpiece: The hardness, toughness, and machinability of the material.

- Type of machining operation: Turning, milling, drilling, or other processes.

- Desired surface finish: The required roughness or smoothness of the finished surface.

- Cutting speed and feed rate: The optimal speed at which the tool cuts the material.

- Tool geometry: The shape, size, and angles of the cutting tool’s cutting edges.

- Tool material: The type of material used to make the cutting tool, such as carbide, high-speed steel, or diamond.

- Tool coating: Coatings applied to the cutting tool to improve its performance and durability.

8. How do you measure and maintain the accuracy of measuring tools?

- Use calibrated gauges, micrometers, and other measuring instruments to measure with precision.

- Follow standard calibration procedures and use certified calibration blocks to verify accuracy.

- Perform regular inspections and clean measuring tools to maintain their accuracy and prevent errors.

- Store measuring tools in controlled environments to minimize temperature and humidity fluctuations that can affect accuracy.

- Document calibration and inspection records for traceability and quality control purposes.

9. What are the different types of welding processes and their applications?

- Arc Welding: Electric arc is used to melt the metal, including MIG (metal inert gas), TIG (tungsten inert gas), and stick welding.

- Gas Welding: Uses a fuel gas and oxygen to produce a flame that melts the metal, such as oxy-acetylene welding.

- Resistance Welding: Heat is generated by electrical resistance between two pieces of metal under pressure, such as spot welding.

- Laser Welding: A focused laser beam melts the metal, providing precise and high-quality welds.

- Electron Beam Welding: Uses a high-energy electron beam to create deep and narrow welds in a vacuum.

10. Describe your experience in maintaining and repairing pneumatic systems.

- Troubleshoot and repair leaks in pneumatic systems, identify and replace faulty components.

- Maintain pneumatic cylinders, valves, and air compressors to ensure optimal performance.

- Install new pneumatic systems and components, following manufacturer’s specifications and industry standards.

- Conduct regular inspections and preventive maintenance to minimize downtime and extend the lifespan of pneumatic systems.

- Familiar with various types of pneumatic control systems, including programmable logic controllers (PLCs).

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Mechanics play a crucial role in maintaining the smooth functioning of industrial machinery and equipment. Their key responsibilities include:

1. Repair and Maintenance

Diagnosing and repairing malfunctioning tools, machines, and equipment.

- Inspecting and testing tools to identify potential problems.

- Disassembling, repairing, and reassembling tools and machinery.

2. Troubleshooting

Identifying and resolving problems with tools and equipment during operation.

- Analyzing error codes and diagnostic reports.

- Conducting root cause analysis to determine the underlying cause of issues.

3. Calibration and Adjustment

Ensuring that tools and gauges meet specified accuracy and precision standards.

- Calibrating measuring instruments using specialized equipment.

- Adjusting machines and tools for optimal performance.

4. Preventive Maintenance

Performing regular maintenance tasks to prevent equipment failures.

- Conducting inspections and cleaning.

- Replacing parts and components as needed.

Interview Tips

To ace the Tool Mechanic interview, candidates should consider the following tips:

1. Research the Company and Role

Gather information about the company’s industry, products, and culture. Understand the specific requirements and responsibilities of the Tool Mechanic position.

- Example: Research the company’s website, LinkedIn page, and industry news.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in tool repair, troubleshooting, calibration, and preventive maintenance. Provide specific examples of successful projects or challenges you have handled.

- Example: “In my previous role, I was responsible for calibrating and maintaining a fleet of CNC machines, which resulted in a 15% reduction in downtime.”

3. Demonstrate Problem-Solving Abilities

Tool Mechanics are often faced with unexpected issues. Showcase your logical thinking and problem-solving skills by describing how you approach complex problems.

- Example: Describe a situation where you diagnosed and resolved a tool failure using a systematic approach.

4. Emphasize Safety Consciousness

Safety is paramount in manufacturing environments. Highlight your adherence to safety protocols and your ability to operate equipment safely.

- Example: “I always follow proper lockout/tagout procedures and wear appropriate PPE to ensure a safe work environment.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!