Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Welding Systems and Equipment Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

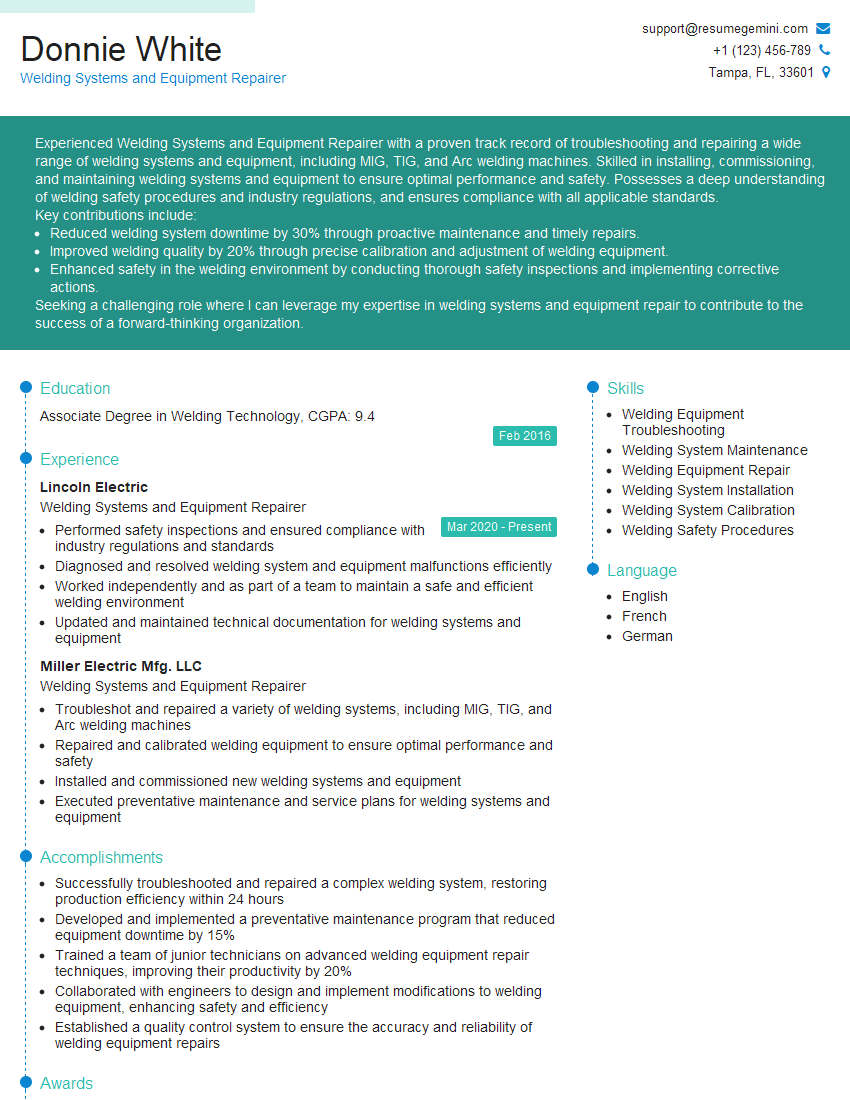

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Systems and Equipment Repairer

1. Describe the steps you take to troubleshoot a welding system?

- Verify the power supply and make sure it is within the specified range.

- Check all electrical connections, including the ground, to ensure they are tight and free of corrosion.

- Examine the welding torch and cables for any damage or wear that could cause arcing or poor conductivity.

- Inspect the shielding gas system for any leaks or restrictions that could affect the welding process.

- Check the welding machine’s settings to ensure they are appropriate for the material and thickness being welded.

2. Explain the different types of welding rods and their applications.

AWS E60XX

- For general-purpose welding of mild steel

- Available in different diameters and lengths

AWS E70XX

- For welding high-strength steels

- Provides greater strength and toughness than E60XX rods

AWS E308L

- For welding stainless steel

- Contains low carbon content to prevent sensitization and corrosion

3. How do you determine the appropriate welding parameters for a specific welding job?

The appropriate welding parameters depend on several factors, including:

- Material thickness

- Material composition

- Welding process

- Joint design

- Desired weld quality

4. Describe the safety precautions you take when performing welding operations.

- Wear appropriate personal protective equipment, including a welding helmet, gloves, and fire-resistant clothing.

- Ensure proper ventilation to prevent inhalation of welding fumes.

- Maintain a clean and organized work area to prevent tripping hazards and fire.

- Inspect welding equipment regularly and make sure it is in good working order.

- Follow safe welding practices, such as avoiding welding on wet surfaces or near flammable materials.

5. How do you stay updated on the latest welding techniques and technologies?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Take online courses and webinars.

- Network with other welding professionals.

- Research new welding equipment and materials.

6. Describe the different types of welding joints and their advantages and disadvantages.

Butt Joint

- Two pieces of metal are joined edge-to-edge.

- Advantages: Strong, easy to prepare, economical.

- Disadvantages: Requires precise alignment, can be difficult to weld on thick materials.

Edge Joint

- Two pieces of metal are joined at their edges.

- Advantages: Strong, leak-proof.

- Disadvantages: Requires special preparation, can be time-consuming to weld.

T-Joint

- One piece of metal is placed perpendicular to another.

- Advantages: Versatile, easy to prepare.

- Disadvantages: Not as strong as other joints, can be difficult to weld on thick materials.

7. What is the difference between MIG and TIG welding?

- MIG (Metal Inert Gas) Welding: Uses a continuously fed wire electrode and a shielding gas to protect the weld pool.

- TIG (Tungsten Inert Gas) Welding: Uses a non-consumable tungsten electrode and a shielding gas to protect the weld pool.

- MIG welding is faster and more economical, while TIG welding produces higher-quality welds with greater precision.

8. Explain the principles of arc welding.

- An electric arc is created between a welding electrode and the base metal.

- The intense heat of the arc melts the base metal and filler metal (if used), forming a weld pool.

- As the electrode is moved along the joint, the weld pool solidifies, creating a permanent bond.

9. What are the different types of welding machines?

Transformer-Based Welding Machine

- Uses a transformer to step down the voltage and increase the current.

- Advantages: Durable, reliable, relatively inexpensive.

- Disadvantages: Heavy, bulky, not as portable as other types.

Inverter-Based Welding Machine

- Uses an inverter to convert AC power to DC power.

- Advantages: Lightweight, portable, energy-efficient.

- Disadvantages: More expensive than transformer-based machines.

10. How do you test the quality of a weld?

Visual Inspection

- Examine the weld for any visible defects, such as cracks, porosity, or undercut.

Non-Destructive Testing

- Radiographic Testing (RT): Uses X-rays or gamma rays to reveal internal defects.

- Ultrasonic Testing (UT): Uses sound waves to detect defects below the surface.

- Magnetic Particle Testing (MT): Uses magnetic particles to detect surface cracks.

Destructive Testing

- Tensile Testing: Measures the strength of a weld by pulling it apart.

- Bend Testing: Measures the ductility of a weld by bending it until it breaks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Systems and Equipment Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Systems and Equipment Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Systems and Equipment Repairers play a crucial role in ensuring the efficient and safe operation of welding systems. Their key job responsibilities include:

1. Equipment Maintenance and Repair

Performing preventive maintenance, troubleshooting, and repairs on welding systems, equipment, and tools. Diagnosing and resolving problems, ensuring optimal performance and safety of welding equipment.

2. Troubleshooting and Calibration

Identifying and resolving issues with welding systems, including electrical, mechanical, and software problems. Calibrating and adjusting equipment to meet industry standards and manufacturer specifications.

3. Installation and Commissioning

Installing, setting up, and commissioning new welding systems. Verifying proper operation and performance of equipment before handing over to production.

4. Safety and Compliance

Ensuring compliance with safety regulations and standards. Conducting safety inspections, adhering to OSHA and other industry-specific requirements.

Interview Tips

To ace the interview for a Welding Systems and Equipment Repairer position, candidates should consider the following preparation tips:

1. Research the Company and Industry

Research the company’s history, products, and services to demonstrate your interest and understanding of their business. Familiarize yourself with industry trends and technologies.

2. Highlight Relevant Skills and Experience

Emphasize your technical expertise in welding systems and equipment repair. Showcase your proficiency in troubleshooting, maintenance, and installation tasks. Quantify your experience with specific examples.

3. Prepare for Technical Questions

Practice answering questions related to welding equipment, maintenance procedures, and industry standards. Study common troubleshooting scenarios and demonstrate your ability to identify and resolve problems.

4. Showcase Safety Consciousness

Highlight your commitment to safety by discussing your adherence to industry regulations and best practices. Emphasize your experience in conducting risk assessments and implementing safety measures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welding Systems and Equipment Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!