Are you gearing up for a career in Grease Packer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Grease Packer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

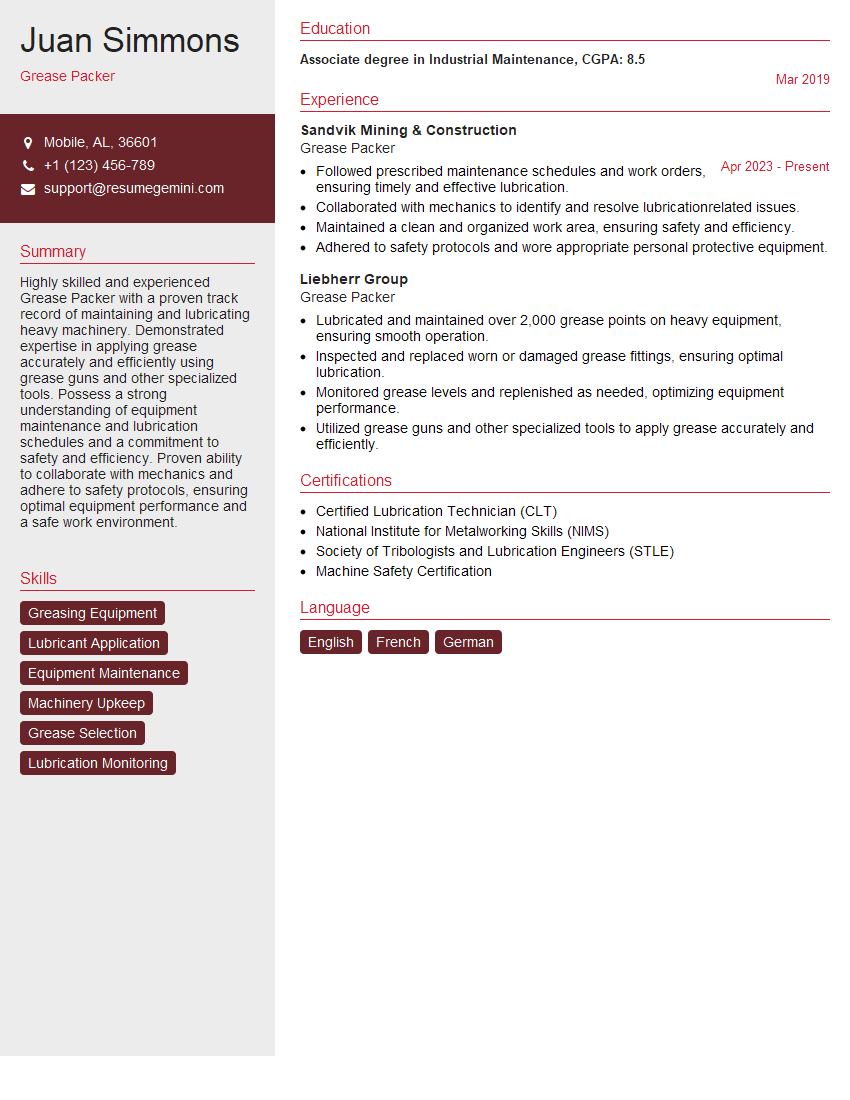

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grease Packer

1. What are the key responsibilities of a Grease Packer?

As a Grease Packer, I am responsible for performing a variety of tasks related to the packaging and distribution of grease. Some of my key responsibilities include:

- Preparing and loading grease into containers and machines

- Operating and maintaining greasing equipment

- Inspecting and ensuring the quality of grease

- Maintaining a clean and organized work area

- Following safety protocols and procedures

2. What types of machinery and equipment are you familiar with operating?

I am familiar with operating a variety of machinery and equipment used in the packaging and distribution of grease, including:

- Grease pumps

- Filling machines

- Capping machines

- Labeling machines

- Forklifts

3. How do you ensure the quality of the grease being packaged?

I ensure the quality of the grease being packaged by performing a series of inspections and checks, including:

- Visual inspection of the grease for any impurities or foreign objects

- Checking the consistency and texture of the grease

- Testing the grease using a grease gun to ensure it flows smoothly

- Regularly calibrating and maintaining greasing equipment to ensure accurate measurements

4. What safety protocols and procedures do you follow when working with grease?

When working with grease, I follow a number of safety protocols and procedures to ensure my safety and the safety of others, including:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a mask

- Using proper lifting techniques to avoid injury

- Keeping the work area clean and organized to prevent slips and falls

- Following lockout/tagout procedures when working on machinery

- Being aware of the potential hazards of grease, such as its flammability and toxicity

5. How do you handle and resolve any issues that may arise during the greasing process?

During the greasing process, I may encounter various issues that require troubleshooting and resolution. Some common issues and my approach to handling them include:

- Clogged grease gun: I would first try to clear the clog by pushing a small wire or needle through the nozzle. If that doesn’t work, I would disassemble the grease gun and clean it thoroughly.

- Leaking grease: I would identify the source of the leak and tighten any loose connections or replace any worn-out seals.

- Grease not flowing smoothly: I would check the consistency of the grease and make sure it is not too thick or cold. I would also check the grease gun and make sure it is properly lubricated.

6. How do you maintain a clean and organized work area?

Maintaining a clean and organized work area is essential for both safety and efficiency. I follow these practices to ensure a clean workspace:

- Regularly sweep and clean the floor to remove any grease spills or debris.

- Keep all tools and equipment in their designated places.

- Dispose of empty grease containers and other waste materials promptly.

- Report any spills or leaks immediately so they can be cleaned up.

7. What are your strengths and weaknesses as a Grease Packer?

Strengths:

- Excellent attention to detail and quality control

- Strong work ethic and dedication to safety

- Ability to work independently and as part of a team

- Physical fitness and ability to lift heavy objects

Weaknesses:

- Limited experience with automated greasing systems

- Not yet certified in hazardous waste handling

I am actively working on addressing these weaknesses by seeking training and certification opportunities.

8. What are your career goals and how does this role align with them?

My career goal is to become a Maintenance Technician. This role as a Grease Packer provides me with valuable experience in handling and maintaining equipment, which is a core aspect of maintenance work. It also allows me to develop my problem-solving and troubleshooting skills.

9. Why are you interested in working for our company?

I am interested in working for your company because of its reputation for excellence in the industry. I am particularly impressed by your commitment to quality and safety, which aligns with my own values.

10. Do you have any questions for me about the role or the company?

I do have a few questions:

- What is the typical career path for a Grease Packer within your company?

- Are there any opportunities for professional development or training?

- What are the company’s policies on safety and environmental protection?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grease Packer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grease Packer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Grease Packer, also known as a Lubrication Specialist, plays a crucial role in ensuring the smooth and efficient operation of machinery and equipment. Their primary responsibilities include:

1. Lubrication and Maintenance

Lubricates machinery components, such as bearings, gears, and chains, with appropriate greases, lubricants, and solvents.

- Conducts regular inspections to assess lubrication needs.

- Selects the correct lubricants based on equipment specifications.

2. Equipment Monitoring and Repair

Monitors equipment conditions to detect issues and prevent failures.

- Performs basic repairs and adjustments to ensure optimal performance.

- Reports any significant issues or breakdowns to supervisors.

3. Inventory Management

Maintains an adequate inventory of lubricants, greases, and other supplies.

- Tracks inventory levels and places orders as needed.

- Ensures proper storage and handling of hazardous materials.

4. Safety and Compliance

Observes all safety protocols and follows established procedures.

- Wears appropriate personal protective equipment.

- Adheres to environmental regulations on waste disposal.

Interview Tips

Preparing for a Grease Packer interview requires careful preparation. Here are some valuable tips to help you make a positive impression and increase your chances of success:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and mission. Understand the specific responsibilities and expectations of the Grease Packer role.

- Visit the company website and check out their social media pages.

- Read industry news and articles to stay updated on lubrication practices.

2. Highlight Your Technical Skills

Demonstrate your expertise in lubrication techniques and equipment maintenance. Emphasize your understanding of grease types, application methods, and safety precautions.

- Provide examples of specific machines or equipment you have lubricated successfully.

- Mention any relevant certifications or training programs you have completed.

3. Communicate Your Attention to Detail

Grease Packers must be able to observe equipment closely and detect potential issues. Highlight your ability to pay attention to small details and identify irregularities.

- Describe how you have used your observation skills to prevent breakdowns or identify maintenance needs.

- Share an example of when you noticed a small leak or vibration that could have led to a major problem if ignored.

4. Emphasize Your Safety Consciousness

Safety is paramount in industrial environments. Assure the interviewer that you are committed to following safety protocols and maintaining a clean and organized work area.

- Explain how you handle and dispose of hazardous materials safely.

- Discuss your experience with accident prevention and emergency response procedures.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Grease Packer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Grease Packer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.