Are you gearing up for an interview for a Grinder Machine Knife Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Grinder Machine Knife Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

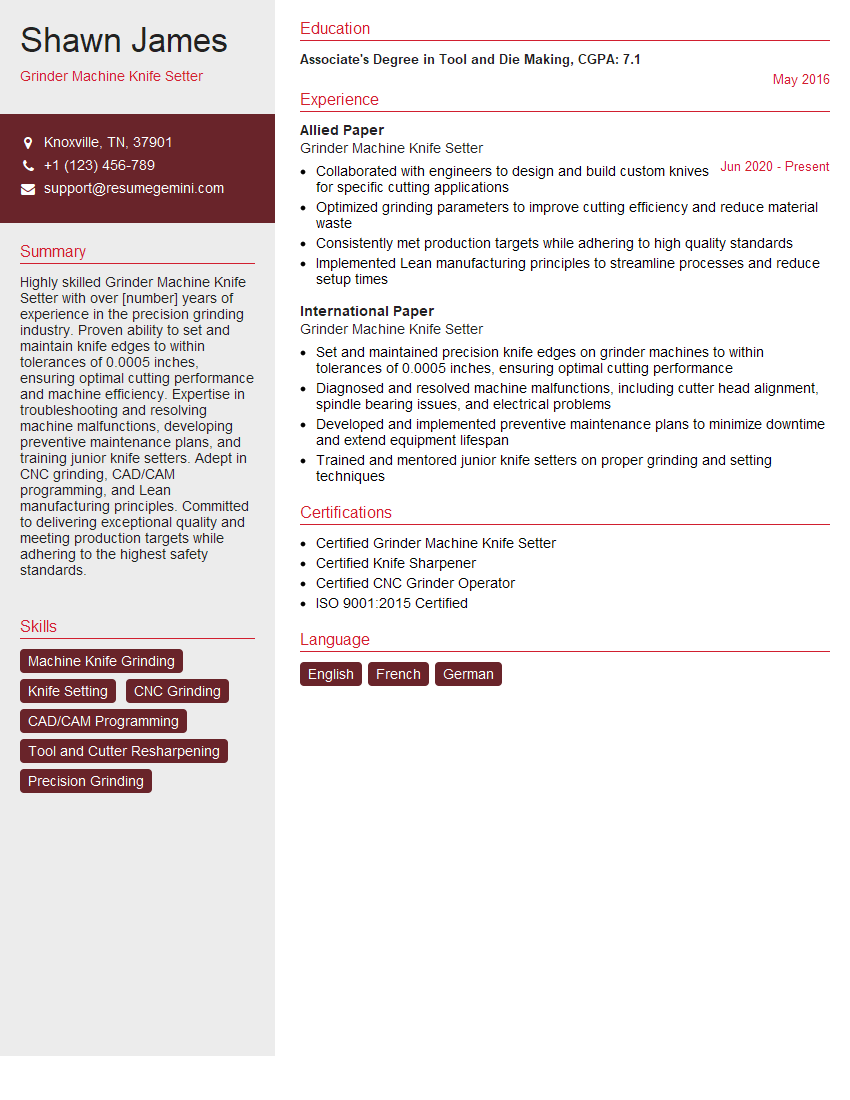

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Grinder Machine Knife Setter

1. Explain the process of setting up a grinder machine for knife sharpening?

The process of setting up a grinder machine for knife sharpening involves several key steps:

- Selecting the appropriate grinding wheel: The type of grinding wheel used depends on the material of the knife blade and the desired sharpness.

- Mounting the grinding wheel: The grinding wheel is mounted on the grinder’s spindle and secured tightly.

- Adjusting the wheel speed: The speed of the grinding wheel is adjusted to suit the type of knife blade and the desired sharpness.

- Positioning the knife: The knife is positioned in the grinder’s chuck or fixture, ensuring it is held securely and at the correct angle to the grinding wheel.

- Applying coolant: A coolant, such as water or oil, is applied to the grinding area to reduce friction and prevent overheating.

2. How do you determine the correct angle for sharpening a knife?

The correct angle for sharpening a knife depends on the type of knife and its intended use:

- Chef’s knives: Typically sharpened at an angle of 15-20 degrees per side.

- Paring knives: Sharpened at a smaller angle of 10-15 degrees per side for increased precision.

- Hunting knives: Sharpened at a steeper angle of 25-30 degrees per side for added durability.

- Serrated knives: Sharpened using a special serrated knife sharpener to maintain the serrations.

3. What techniques do you use to troubleshoot common grinding issues?

Common grinding issues and troubleshooting techniques include:

- Excessive heat generation: Reduce wheel speed, increase coolant flow, or use a coarser grinding wheel.

- Chattering or vibration: Ensure the knife is securely clamped, check wheel balance, or adjust the grinding pressure.

- Irregular grinding: Check the condition of the grinding wheel, adjust the angle of the knife, or use a dressing tool to reshape the wheel.

- Burned or damaged blades: Reduce grinding pressure, increase coolant flow, or use a softer grinding wheel.

4. How do you maintain the accuracy and precision of your grinding machine?

Maintaining accuracy and precision in a grinding machine involves several steps:

- Regular calibration: Calibrate the machine periodically using a precision measuring device.

- Wheel truing and dressing: Use a truing tool to ensure the grinding wheel is perfectly round and balanced, and a dressing tool to remove any glazing or buildup.

- Spindle maintenance: Clean and lubricate the spindle regularly to prevent wear and tear.

- Coolant system maintenance: Ensure the coolant system is functioning properly to provide adequate cooling and lubrication.

5. Describe the safety precautions you observe when operating a grinder machine?

Safety precautions for operating a grinder machine include:

- Wearing appropriate safety gear: Safety glasses, gloves, and earplugs.

- Securing the workpiece: Ensure the knife is securely clamped or held in a fixture.

- Avoiding loose clothing or jewelry: These can get caught in the machine.

- Keeping the work area clean: Debris can create a tripping hazard or interfere with the grinding process.

- Following proper grinding techniques: Avoid excessive pressure or grinding at too high a speed.

6. Explain the different types of grinding wheels used for knife sharpening and their applications?

Types of grinding wheels and their applications for knife sharpening:

Corundum (Aluminum Oxide)

- General-purpose wheel for sharpening most types of knives.

Silicon Carbide

- Suitable for sharpening hard steels and ceramics.

Diamond

- Extremely hard and durable, used for sharpening high-performance and specialty knives.

Ceramic

- Fine-grit wheel used for honing and polishing knife edges.

7. How do you handle situations where customers have specific sharpening requirements?

When handling specific sharpening requirements from customers:

- Listen attentively: Understand the customer’s desired sharpness, angle, and any other specifications.

- Communicate clearly: Explain any limitations or recommendations based on the knife’s material and condition.

- Test and verify: Sharpen the knife to the customer’s specifications and test it to ensure satisfaction.

- Provide guidance: Offer advice on how to maintain the knife’s sharpness and prevent damage.

8. Describe your approach to quality control when sharpening knives?

Quality control measures for knife sharpening:

- Visual inspection: Examine the knife before and after sharpening for any damage or defects.

- Sharpness testing: Use a sharpness tester or cutting test to ensure the knife meets the desired sharpness level.

- Consistency: Sharpen knives to a consistent angle and sharpness across multiple units.

- Customer feedback: Encourage customer feedback to identify any areas for improvement.

9. How do you stay updated on the latest techniques and advancements in knife sharpening?

To stay updated on the latest techniques and advancements in knife sharpening:

- Attend industry workshops and conferences: Learn from experts and share knowledge with peers.

- Read industry publications and online forums: Stay informed about new products, techniques, and best practices.

- Experiment with different methods: Explore new sharpening techniques and materials to improve efficiency and results.

- Seek feedback from experienced professionals: Consult with master sharpeners or knife makers for insights and guidance.

10. Explain how you work effectively in a team environment, especially when deadlines are tight?

Effective teamwork and meeting deadlines:

- Communicate regularly: Inform team members of progress and any challenges encountered.

- Prioritize tasks: Determine the most critical tasks and allocate resources accordingly.

- Delegate responsibilities: Assign tasks based on skills and expertise to optimize efficiency.

- Monitor progress: Track milestones and identify potential bottlenecks to address them promptly.

- Adjust plans as needed: Be flexible and adapt to changes in workload or priorities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Grinder Machine Knife Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Grinder Machine Knife Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Grinder Machine Knife Setters are responsible for the proper functioning and maintenance of grinder machines and their knives. Their primary duties include:

1. Machine Setup and Operation

Setting up and operating grinder machines according to specified parameters.

- Loading and unloading materials.

- Adjusting machine settings for optimal performance.

- Monitoring machine operation and making necessary adjustments.

2. Knife Setting and Sharpening

Sharpening and setting grinder machine knives to precise specifications.

- Selecting the appropriate sharpening method.

- Grinding and honing knives to achieve the desired sharpness and edge geometry.

- Measuring and adjusting knives to ensure accurate cutting.

3. Machine Maintenance

Performing preventive maintenance on grinder machines and knives.

- Inspecting and cleaning machines and knives.

- Replacing worn or damaged parts.

- Calibrating and adjusting machines for optimal performance.

- Troubleshooting and resolving machine malfunctions.

4. Quality Control

Ensuring the quality of grinding operations.

- Inspecting ground materials to meet specifications.

- Identifying and correcting defects.

- Maintaining records of grinding operations for quality assurance purposes.

Interview Tips

To ace an interview for a Grinder Machine Knife Setter position, candidates should prepare by researching the role and practicing their responses to common interview questions. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, operations, and the specific responsibilities of the Grinder Machine Knife Setter role. This knowledge will help you demonstrate your interest in the position and show that you have taken the time to prepare.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

- Connect with current or former employees on LinkedIn.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions, such as:

- Tell me about your experience setting and sharpening knives.

- How do you ensure the quality of your work?

- What are your strengths and weaknesses as a Grinder Machine Knife Setter?

- How do you stay updated on the latest industry trends and technologies?

3. Highlight Your Skills and Experience

Emphasize your technical skills and experience in knife setting and grinding. Quantify your accomplishments whenever possible, using specific examples to demonstrate your abilities.

- Describe the types of grinder machines and knives you have worked with.

- Share examples of successful projects where you set and sharpened knives to precise specifications.

- Explain how you troubleshoot and resolve machine malfunctions independently.

4. Show Passion and Enthusiasm

Convey your passion for the role and your understanding of its importance to the company’s operations. Show that you are eager to learn and contribute to the team.

- Explain why you are interested in the Grinder Machine Knife Setter position.

- Share your knowledge of the industry and how it is evolving.

- Express your desire to make a meaningful contribution to the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Grinder Machine Knife Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.