Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Lubricator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

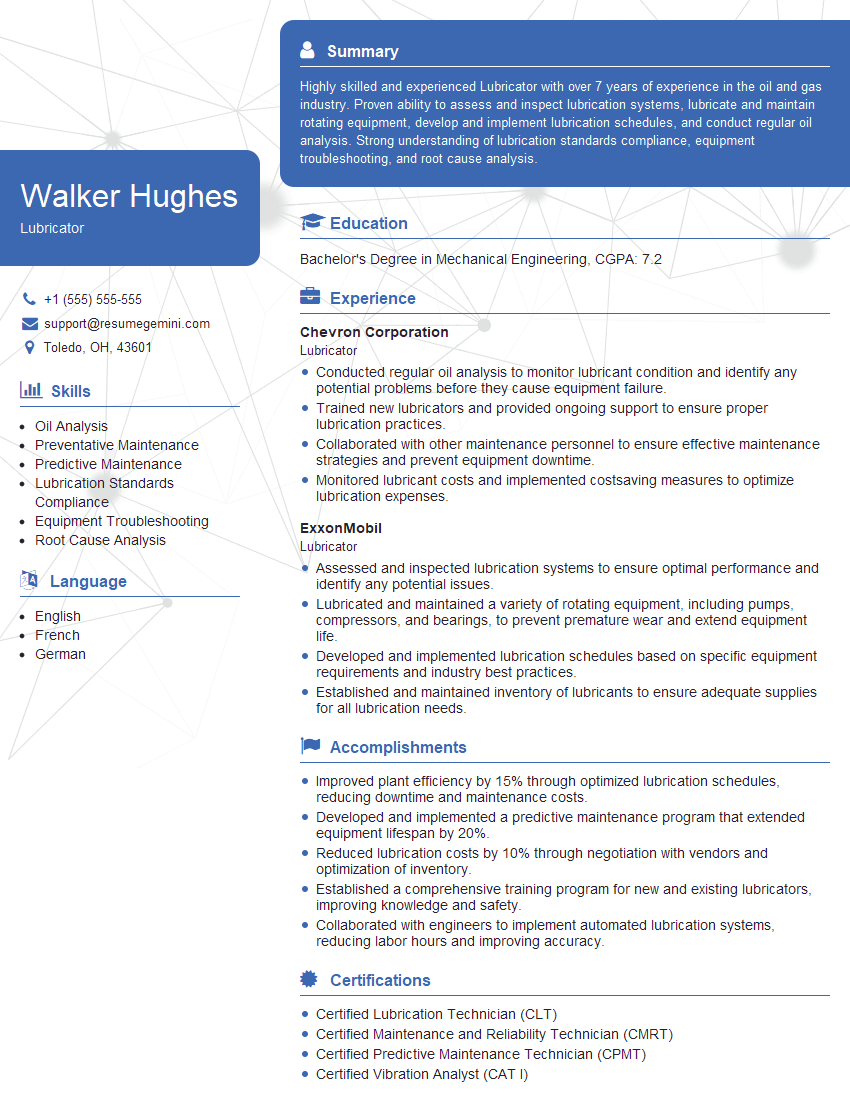

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lubricator

1. What are the different types of lubricants and their applications?

- Oil lubricants: Used for general lubrication, such as in engines, bearings, and gears.

- Grease lubricants: Used for applications where oil lubricants cannot be used, such as in high-temperature or dusty environments.

- Solid lubricants: Used for applications where extreme temperatures or vacuum conditions prevent the use of liquid lubricants.

2. What are the properties of a good lubricant?

Viscosity

- The resistance of a lubricant to flow.

- It should be able to maintain a film between moving parts even under high pressure and temperature.

Wear resistance

- The ability of a lubricant to prevent wear on moving parts.

- Additives can be added to lubricants to enhance wear resistance.

Corrosion resistance

- The ability of a lubricant to protect metal surfaces from corrosion.

- Additives can be added to lubricants to enhance corrosion resistance.

3. What are the common methods of lubrication?

- Manual lubrication: Using an oil can, grease gun, or other manual device to apply lubricant.

- Automatic lubrication: Using a pump or other automatic system to deliver lubricant.

- Mist lubrication: Using an aerosol to create a mist of lubricant that is applied to moving parts.

4. What are the safety precautions that should be taken when working with lubricants?

- Wear appropriate personal protective equipment (PPE), such as gloves and eye protection.

- Do not ingest lubricants or allow them to come into contact with skin.

- Dispose of used lubricants properly according to local regulations.

5. What are the different types of lubrication systems?

- Centralized lubrication systems: Used to automatically lubricate multiple points from a single reservoir.

- Single-line lubrication systems: Used to lubricate a single point from a reservoir.

- Manually operated lubrication systems: Used to manually apply lubricant to lubrication points.

6. What are the factors that can affect the performance of a lubrication system?

- The type of lubricant: The viscosity, wear resistance, and corrosion resistance of the lubricant can affect the performance of the system.

- The lubrication method: The method of lubrication can affect the efficiency of the system.

- The lubrication schedule: The frequency of lubrication can affect the performance of the system.

7. What are the common problems that can occur in lubrication systems?

- Lubricant contamination: Contaminants can enter the lubrication system from the environment or from the lubricated equipment.

- Lubricant starvation: A lack of lubricant can cause the system to fail.

- Lubricant failure: The lubricant can fail to perform its intended function due to wear, contamination, or other factors.

8. How can you troubleshoot problems in a lubrication system?

- Identify the symptoms of the problem.

- Check the lubricant level and condition.

- Inspect the lubrication system for leaks or other problems.

- Consult the manufacturer’s literature for troubleshooting tips.

9. What is the role of a lubricant in a machine’s performance?

- Reduces friction: Lubricants create a film between moving parts, reducing friction and wear.

- Dissipates heat: Lubricants carry heat away from moving parts, preventing overheating.

- Protects against corrosion: Lubricants form a barrier between metal surfaces, protecting them from corrosion.

- Enhances efficiency: By reducing friction and wear, lubricants improve the efficiency of machines.

10. How do you stay up-to-date on the latest lubrication technologies and best practices?

- Attend industry conferences and exhibitions.

- Read trade publications and online resources.

- Network with other lubrication professionals.

- Complete continuing education courses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lubricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lubricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lubricators play a pivotal role in maintaining smooth operation of machinery and equipment, preventing costly downtime and ensuring production efficiency. Their primary responsibilities include:

1. Lubrication and Maintenance

Inspecting and lubricating machinery components, including bearings, gears, and drives, according to established schedules and specifications.

- Applying lubricants manually or using automated systems to ensure optimal performance and prevent wear

- Monitoring and adjusting lubrication systems to maintain proper levels and pressures

2. Equipment Monitoring

Conducting regular visual and auditory inspections of equipment to detect any potential issues or signs of wear.

- Listening for unusual noises or vibrations that may indicate mechanical problems

- Observing equipment operation to identify any deviations from normal functioning

3. Troubleshooting and Repair

Identifying and resolving minor lubrication-related issues to prevent equipment failures.

- Diagnosing lubrication problems and implementing appropriate corrective actions

- Replacing worn or damaged lubrication components such as seals and gaskets

4. Safety and Compliance

Maintaining a clean and safe work environment in accordance with established safety protocols.

- Handling and storing lubricants according to manufacturer instructions and regulatory requirements

- Reporting any hazards or safety concerns to supervisors or designated personnel

Interview Preparation Tips

To enhance your chances of success in a Lubricator interview, consider the following tips:

1. Research the Company and Role

Before the interview, take time to learn about the company’s industry, operations, and the specific requirements of the Lubricator position. This knowledge will demonstrate your interest and enthusiasm for the role.

- Visit the company website to gather information about their products, services, and mission.

- Review industry publications and news articles to stay abreast of current trends and best practices.

- Understand the key responsibilities of a Lubricator and how they align with your skills and experience.

2. Highlight Your Technical Expertise

During the interview, emphasize your proficiency in lubrication techniques, equipment maintenance, and troubleshooting. Provide specific examples of your accomplishments to demonstrate your knowledge and abilities.

- Describe your experience with different types of lubrication systems and how you ensured optimal performance.

- Explain how you have identified and resolved lubrication-related issues to prevent breakdowns and downtime.

- Mention any certifications or training programs you have completed to enhance your technical skills.

3. Emphasize Safety and Compliance

Safety is paramount in lubrication, so highlight your commitment to maintaining a safe work environment. Share your knowledge of industry safety standards and regulations.

- Explain how you comply with safety procedures when handling and storing lubricants.

- Describe your experience in identifying and reporting potential hazards to ensure a safe workplace.

4. Demonstrate Communication and Problem-Solving Abilities

Lubricators often work independently but must also collaborate with other maintenance personnel. Showcase your strong communication skills and ability to solve problems effectively.

- Provide examples of how you have effectively communicated with team members to ensure smooth equipment operation.

- Discuss how you approach problem-solving situations, analyze potential causes, and implement solutions.

5. Ask Thoughtful Questions

At the end of the interview, prepare thoughtful questions to demonstrate your interest in the position and the company. This shows that you are engaged and eager to learn more.

- Ask about opportunities for professional development and advancement within the organization.

- Inquire about the company’s approach to maintaining equipment reliability and efficiency.

- Ask about the specific challenges or projects that the Lubricator may encounter in this role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lubricator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.