Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lubrication Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lubrication Worker so you can tailor your answers to impress potential employers.

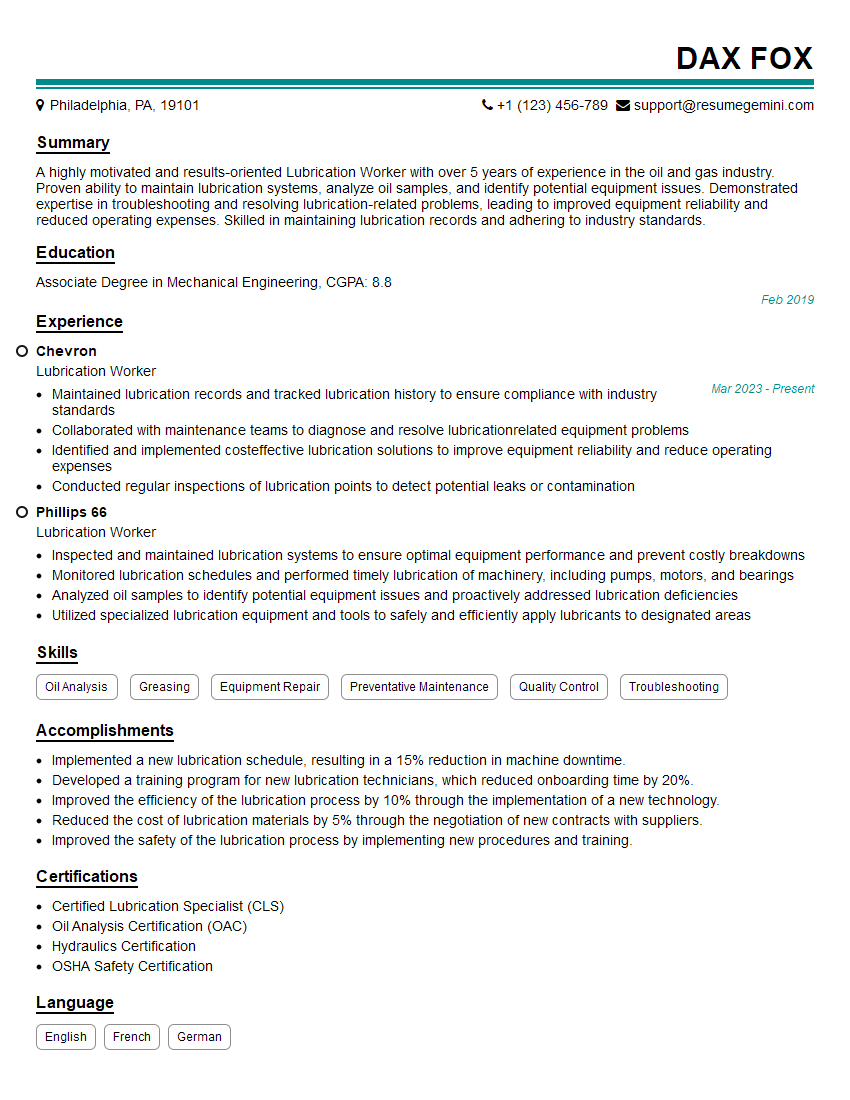

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lubrication Worker

1. Which types of lubricants are commonly used in industrial settings? Explain their key characteristics and applications.

- Oils: Mineral oils, synthetic oils, and bio-based oils provide lubrication through a film between surfaces, reducing friction and wear. They are commonly used in engines, gearboxes, and hydraulic systems.

- Greases: Semi-solid mixtures of oil and thickeners, greases offer long-term lubrication with minimal leakage. They are suitable for bearings, couplings, and other applications where oil retention is crucial.

- Dry lubricants: Solid materials like graphite and molybdenum disulfide reduce friction and wear without the need for liquid lubrication. They are used in high-temperature, vacuum, or clean applications.

2. How do you determine the proper lubrication schedule for different equipment?

- Review manufacturer’s recommendations and specifications.

- Consider operating conditions, such as load, speed, and temperature.

- Monitor equipment performance and adjust schedules based on observed wear patterns.

subheading of the answer

- Use lubrication analysis techniques (e.g., oil sampling) to track lubricant condition and identify potential issues.

- Consult with experienced technicians or lubrication engineers for guidance.

3. What types of lubrication systems are commonly used, and how do you select the most appropriate one for a given application?

- Manual lubrication: Simple and cost-effective, but requires regular attention and can lead to inconsistent lubrication.

- Automatic lubrication: Uses pumps, timers, or other devices to deliver lubrication at predetermined intervals, ensuring consistent and reliable lubrication.

- Centralized lubrication: A network of pipes and valves that distributes lubricant to multiple points, reducing downtime and maintenance costs.

4. What are some common lubrication-related problems, and how do you troubleshoot and resolve them?

- Over-lubrication: Can lead to lubricant leakage, reduced efficiency, and increased contamination.

- Under-lubrication: Causes increased friction, wear, and potential equipment failure.

- Contaminated lubricant: Can damage equipment components and affect lubricant performance.

5. How do you stay up-to-date with the latest lubrication practices and technologies?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Consult with lubricant manufacturers and distributors.

6. How do you ensure safety when handling and applying lubricants?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and respirators.

- Follow manufacturer’s instructions for handling and disposal.

- Maintain a clean and organized work environment.

7. What are the environmental impacts of lubrication, and how do you minimize them?

- Lubricants can contaminate soil and water if not disposed of properly.

- Use biodegradable lubricants or lubricants with extended drain intervals to reduce waste.

- Implement recycling programs for used lubricants.

8. How do you handle emergencies related to lubrication, such as spills or fires?

- Immediately stop the source of the spill or fire.

- Contain the spill using absorbent materials.

- Evacuate the area if necessary.

subheading of the answer

- Follow emergency response protocols and notify authorities as required.

- Clean up the spill or fire using appropriate methods.

9. How do you work effectively as part of a team, particularly with technicians and engineers?

- Communicate clearly and effectively.

- Provide timely and accurate information.

- Offer support and assistance when needed.

subheading of the answer

- Respect the expertise and contributions of others.

- Be willing to learn from more experienced colleagues.

10. Why are you interested in working as a Lubrication Worker, and what sets you apart from other candidates?

- Highlight your passion for machinery and mechanical systems.

- Emphasize your attention to detail and commitment to safety.

- Describe any relevant training or experience that makes you a qualified candidate.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lubrication Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lubrication Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lubrication Workers are responsible for the lubrication of machinery and other equipment to minimize friction, wear, and corrosion, thereby extending the equipment life. They use various tools and equipment to apply lubricants to moving parts, such as gears, bearings, and chains.

1. Lubrication

Their primary responsibility is to lubricate machinery and other equipment according to the manufacturer’s specifications.

- Identify and gather the necessary lubricants and tools

- Apply lubricants to moving parts using grease guns, oil cans, or other tools

- Ensure that the proper amount of lubricant is applied

2. Equipment Monitoring

Monitor equipment for signs of wear or damage and report any issues to the supervisor.

- Inspect equipment for leaks, unusual noises, or vibrations

- Check lubricant levels and condition

- Report any observed problems to the supervisor

3. Maintenance and Repair

Perform basic maintenance and repair tasks on lubrication systems.

- Clean and replace filters and screens

- Repair or replace worn or damaged parts

- Inspect and maintain lubrication equipment

4. Safety

Comply with all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE)

- Use lubricants safely and properly

- Dispose of used lubricants and rags properly

- Maintain a clean and organized work area

Interview Tips

To prepare for an interview for a lubrication worker position, it is essential to highlight your skills and experience in lubrication, equipment maintenance, and safety. Research the company and the specific role to tailor your answers accordingly.

1. Research the Company and Position

Before the interview, thoroughly research the company, its industry, and the specific lubrication worker position.

- Visit the company’s website to learn about their products, services, and culture

- Read industry news and articles to stay updated on current trends

- Review the job description carefully to identify the key responsibilities and qualifications

2. Prepare Examples of Your Skills and Experience

Highlight your relevant skills and experience in the lubrication field. Use specific examples to demonstrate your abilities.

- Provide examples of times when you successfully lubricated and maintained machinery

- Describe situations where you identified and resolved lubrication-related issues

- Mention any certifications or training you have in lubrication or related fields

3. Emphasize Safety and Attention to Detail

Safety and attention to detail are crucial in lubrication work. Emphasize your commitment to these aspects.

- Explain how you prioritize safety and follow established protocols

- Describe your experience in identifying and mitigating potential hazards

- Highlight your ability to follow instructions precisely and pay attention to detail

4. Be Enthusiastic and Professional

Show your enthusiasm for the lubrication worker role and demonstrate a professional demeanor throughout the interview.

- Convey your passion for lubrication and equipment maintenance

- Ask thoughtful questions to demonstrate your interest and engagement

- Dress appropriately and arrive on time for the interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lubrication Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!