Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Looper Fixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

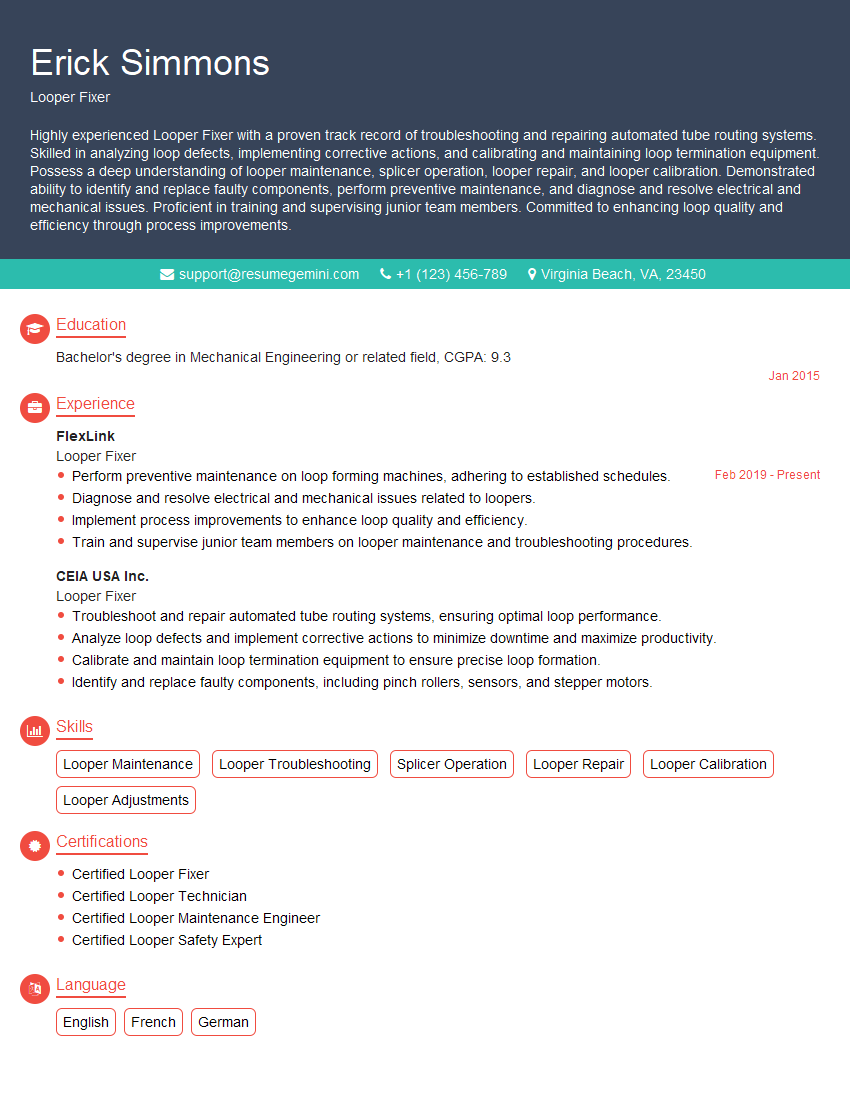

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Looper Fixer

1. What are the key steps involved in troubleshooting a looper fixer on a sewing machine?

Sample Answer:

- Inspect the looper for any visible damage or wear.

- Check the looper thread path for any obstructions or tangles.

- Adjust the looper timing to ensure proper synchronization with the needle.

- Lubricate the looper and surrounding components as necessary.

- Test the looper functionality by sewing a sample fabric.

2. Describe the different types of looping systems used in sewing machines.

Overlock Looping System

- Uses two loopers to create a chain stitch.

- Produces a strong and stretchy seam.

Coverstitch Looping System

- Employs three loopers to create a cover stitch.

- Produces a decorative and reinforced seam.

3. How do you ensure that the looper is properly synchronized with the needle?

Sample Answer:

- Use a timing gauge to check the distance between the looper and the needle.

- Adjust the looper timing screw or gear to achieve the correct timing.

- Sew a sample fabric to verify that the needle and looper are synchronized.

4. What are the common causes of thread breakage in a looper fixer?

Sample Answer:

- Incorrect looper timing.

- Damaged or worn looper.

- Obstructions in the thread path.

- Insufficient lubrication.

- Poor thread quality.

5. How do you test the functionality of a looper fixer after repairs?

Sample Answer:

- Manually rotate the looper to check for smooth operation.

- Sew a sample fabric to ensure proper stitch formation.

- Inspect the stitch quality for any defects or irregularities.

6. Describe the safety precautions that should be taken when working on a looper fixer.

Sample Answer:

- Unplug the sewing machine before performing any maintenance.

- Wear appropriate safety gear, including gloves and safety glasses.

- Be aware of sharp edges and moving parts.

- Use caution when handling needles and thread.

7. How do you maintain a looper fixer to prevent future issues?

Sample Answer:

- Regularly clean and lubricate the looper and surrounding components.

- Inspect the looper for any damage or wear.

- Adjust the looper timing as needed.

- Use high-quality thread to prevent breakage.

8. What troubleshooting techniques can you use to diagnose and resolve looper fixer problems?

Sample Answer:

- Visual inspection for damage or obstructions.

- Checking looper timing using a timing gauge.

- Testing thread path for smoothness and tension.

- Lubricating and adjusting components as necessary.

9. How do you handle complex looper fixer issues that require specialized knowledge or skills?

Sample Answer:

10. What is your understanding of the latest advancements and technologies in looper fixer systems?

Sample Answer:

- Improved looper designs for enhanced stitch quality and efficiency.

- Automatic looper timing systems for precise synchronization.

- Computer-controlled loopers for increased accuracy and repeatability.

- Advanced materials and coatings for reduced wear and improved durability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Looper Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Looper Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Looper Fixer plays a vital role in the manufacturing process, ensuring that production lines operate smoothly and efficiently. Their responsibilities encompass a wide range of tasks, including:

1. Maintain and Repair Production Equipment

Looper Fixers are responsible for maintaining and repairing a variety of production equipment, including loopers, knotters, and other machinery. They must be able to diagnose problems quickly and efficiently, and make the necessary repairs to keep the equipment running smoothly.

- Conduct regular inspections of equipment to identify potential problems.

- Troubleshoot and diagnose equipment malfunctions, using diagnostic tools and techniques.

- Perform repairs and replacements of faulty components, using specialized tools and equipment.

- Adjust and calibrate equipment to ensure optimal performance and efficiency.

2. Troubleshoot and Resolve Production Issues

Looper Fixers are also responsible for troubleshooting and resolving production issues. They must be able to identify the root cause of problems and develop solutions to prevent them from recurring.

- Identify and analyze production bottlenecks and inefficiencies.

- Develop and implement solutions to improve production efficiency and quality.

- Work with other team members to identify and resolve production problems.

- Document and track production issues and repairs for future reference.

3. Ensure Quality Standards

Looper Fixers play a critical role in ensuring that production meets quality standards. They must be able to identify and correct defects in products, and ensure that all products meet the required specifications.

- Inspect products for defects and non-conformances.

- Identify and correct defects in products, using appropriate tools and techniques.

- Ensure that all products meet the required quality standards.

- Provide feedback to production staff on quality issues and improvements.

4. Safety and Compliance

Looper Fixers must also ensure that all work is performed in a safe and compliant manner. They must be familiar with all relevant safety regulations and procedures, and must follow them at all times.

- Follow all safety regulations and procedures.

- Identify and mitigate potential safety hazards.

- Use personal protective equipment (PPE) as required.

- Report any safety concerns or incidents to supervisors.

Interview Tips

Preparing for an interview can be daunting, but by following these tips, you can increase your chances of success:

1. Research the Company and the Role

Before the interview, take some time to research the company and the role you are applying for. This will help you understand the company’s culture, values, and goals, and will make you better prepared to answer questions about your qualifications.

- Visit the company’s website to learn about their history, products, and services.

- Read the job description carefully and identify the key skills and qualifications required.

- Check out the company’s social media pages to get a sense of their culture and values.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this role?”. Take some time to practice answering these questions in a clear and concise manner.

- Use the STAR method to answer behavioral questions (Situation, Task, Action, Result).

- Focus on highlighting your skills and experience that are relevant to the role.

- Be prepared to share examples of your work and accomplishments.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the opportunity.

- Wear clean, pressed clothes that are appropriate for the role.

- Arrive at the interview location 10-15 minutes early.

- Bring a portfolio or resume to the interview.

4. Be Enthusiastic and Confident

Employers are looking for candidates who are enthusiastic and confident about their abilities. Be yourself and don’t be afraid to show your passion for the role and the company.

- Make eye contact with the interviewer and speak clearly and confidently.

- Smile and be positive throughout the interview.

- Ask questions at the end of the interview to show your interest and engagement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Looper Fixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.