Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Machine Oiler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Machine Oiler so you can tailor your answers to impress potential employers.

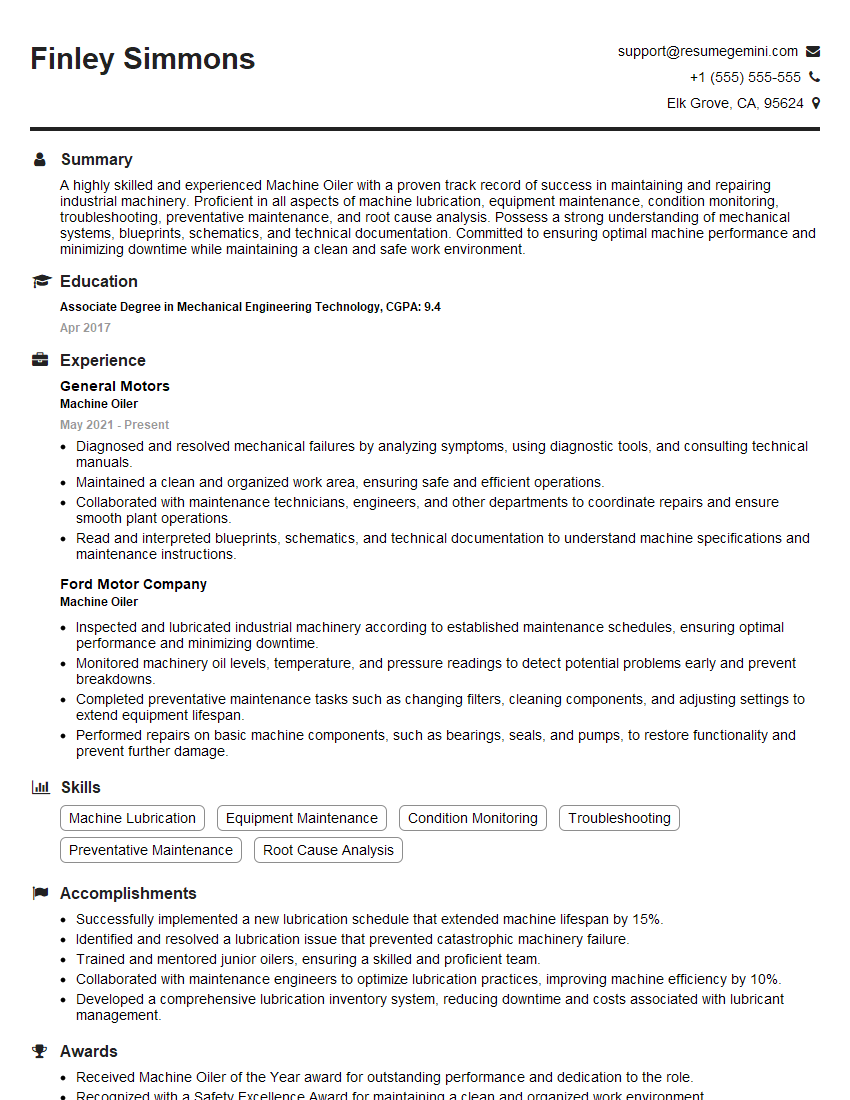

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Oiler

1. What steps do you take to lubricate a machine?

- Identify and locate all lubrication points on the machine.

- Clean the lubrication points to remove any dirt or debris.

- Apply the correct type and amount of lubricant to each point.

- Inspect the machine after lubrication to ensure that all points have been lubricated properly.

2. What are the different types of lubricants used in machines?

Petroleum-based lubricants

- Mineral oil

- Synthetic oil

Non-petroleum-based lubricants

- Water-based lubricants

- Solid lubricants

3. What are the properties of a good lubricant?

- Low friction

- High viscosity

- Good adhesion

- Resistance to wear and tear

- Corrosion protection

4. What are the common causes of machine failure due to lubrication problems?

- Inadequate lubrication

- Contaminated lubrication

- Wrong type of lubrication

- Improper lubrication schedule

5. What are the safety precautions to be taken while lubricating machines?

- Wear appropriate personal protective equipment (PPE)

- Use caution when handling lubricants

- Avoid contact with skin and eyes

- Clean up any spills immediately

6. What are the different types of lubrication systems?

- Manual lubrication

- Automatic lubrication

- Centralized lubrication

7. What are the advantages and disadvantages of manual lubrication?

Advantages

- Simple and inexpensive

- Easy to implement

- Can be customized to specific needs

Disadvantages

- Labor-intensive

- Can be inconsistent

- Can lead to over or under lubrication

8. What are the advantages and disadvantages of automatic lubrication?

Advantages

- Consistent lubrication

- Reduced labor costs

- Protects equipment from wear and tear

Disadvantages

- More expensive than manual lubrication

- Can be complex to install and maintain

- May not be suitable for all applications

9. What are the advantages and disadvantages of centralized lubrication?

Advantages

- Provides consistent lubrication to multiple points

- Reduces downtime for lubrication

- Improves equipment reliability

Disadvantages

- Initial investment can be high

- System can be complex and requires maintenance

- May not be suitable for all applications

10. What are some of the key maintenance tasks for a machine oiler?

- Lubrication of machinery

- Monitoring oil levels

- Changing oil filters

- Inspecting equipment for leaks

- Maintaining lubrication schedules

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Machine Oiler is responsible for ensuring that the machinery in a plant or factory runs smoothly by lubricating and maintaining it. They play a crucial role in preventing breakdowns and ensuring the safety and efficiency of the production process.

1. Lubrication and Maintenance

The primary responsibility of a Machine Oiler is to lubricate machinery using oil, grease, and other lubricants. They must follow lubrication schedules and use the correct type of lubricant for each machine component.

- Apply lubricants to bearings, gears, chains, and other moving parts.

- Monitor oil levels and refill as needed.

- Inspect and clean machinery regularly to identify any potential problems.

2. Troubleshooting and Repair

Machine Oilers are often the first to identify and troubleshoot mechanical issues. They must have a good understanding of the machinery they work with and be able to diagnose and resolve common problems.

- Identify and fix minor mechanical issues.

- Report major problems to supervisors or maintenance technicians.

- Assist with repairs and maintenance projects.

3. Safety and Compliance

Machine Oilers must adhere to safety regulations and ensure that the machinery they maintain meets safety standards. They must also follow environmental regulations related to the handling and disposal of lubricants.

- Ensure that machinery is properly lubricated and maintained to prevent accidents.

- Wear appropriate safety gear and follow safety procedures.

- Dispose of lubricants and other materials in accordance with environmental regulations.

4. Communication and Teamwork

Machine Oilers work with other members of the maintenance team and communicate with supervisors and operators to ensure that the machinery is running smoothly. They must be able to clearly communicate any issues or concerns.

- Work collaboratively with other maintenance personnel.

- Communicate with supervisors and operators to report issues and receive instructions.

- Document maintenance activities and any problems encountered.

Interview Tips

To ace an interview for a Machine Oiler position, it is essential to highlight your technical skills, problem-solving abilities, and attention to detail. Here are some tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Machine Oiler position you are applying for. This will demonstrate your interest and enthusiasm for the role and allow you to ask informed questions during the interview.

- Visit the company website and read about their history, products/services, and industry.

- Review the job description and identify the key responsibilities and qualifications.

- Consider how your skills and experience align with the company’s needs.

2. Highlight Your Technical Skills

Emphasize your knowledge of lubrication practices, mechanical maintenance, and troubleshooting techniques. Provide specific examples of your experience in these areas.

- Describe the different types of lubricants you have used and the machinery you have lubricated.

- Explain how you troubleshoot and resolve common mechanical problems.

- Mention any certifications or training you have received in lubrication or maintenance.

3. Showcase Your Problem-Solving Abilities

Machine Oilers are often required to identify and solve mechanical issues. Describe situations where you have successfully diagnosed and fixed problems.

- Provide an example of a time when you identified a potential problem and took steps to prevent it from becoming a major issue.

- Explain how you troubleshoot and repair equipment using logical thinking and problem-solving techniques.

- Emphasize your ability to remain calm and focused under pressure.

4. Demonstrate Attention to Detail

Machine Oilers must be able to follow lubrication schedules, inspect machinery, and adhere to safety regulations. Highlight your attention to detail and commitment to accuracy.

- Describe how you ensure that machinery is properly lubricated and maintained.

- Explain how you follow safety procedures and ensure compliance with environmental regulations.

- Provide an example of a time when you identified a potential safety hazard and took steps to mitigate it.

5. Be Prepared for Physical Tasks

Machine Oilers may be required to perform physical tasks such as lifting heavy objects or climbing ladders. Be prepared to discuss your physical capabilities and any limitations you may have.

- Explain how you maintain your physical fitness and meet the demands of the job.

- If you have any physical limitations, be upfront about them and explain how they may impact your performance.

- Be prepared to demonstrate your ability to lift heavy objects if necessary.

6. Practice Your Answers

To prepare for the interview, practice answering common interview questions related to your skills, experience, and qualifications. This will help you deliver clear and concise responses during the actual interview.

- Prepare answers to questions about your lubrication and maintenance experience, problem-solving abilities, and attention to detail.

- Practice describing your experience and accomplishments using the STAR method (Situation, Task, Action, Result).

- Have questions ready to ask the interviewer to demonstrate your interest and enthusiasm.

7. Dress Professionally and Be On Time

First impressions matter. Dress professionally and arrive at the interview on time. This demonstrates your respect for the interviewer and the company.

- Wear clean and pressed business attire.

- Arrive at the interview 10-15 minutes early to allow for any unexpected delays.

- Be polite and respectful to the receptionist and anyone else you encounter.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Machine Oiler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.