Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Oiler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Oiler so you can tailor your answers to impress potential employers.

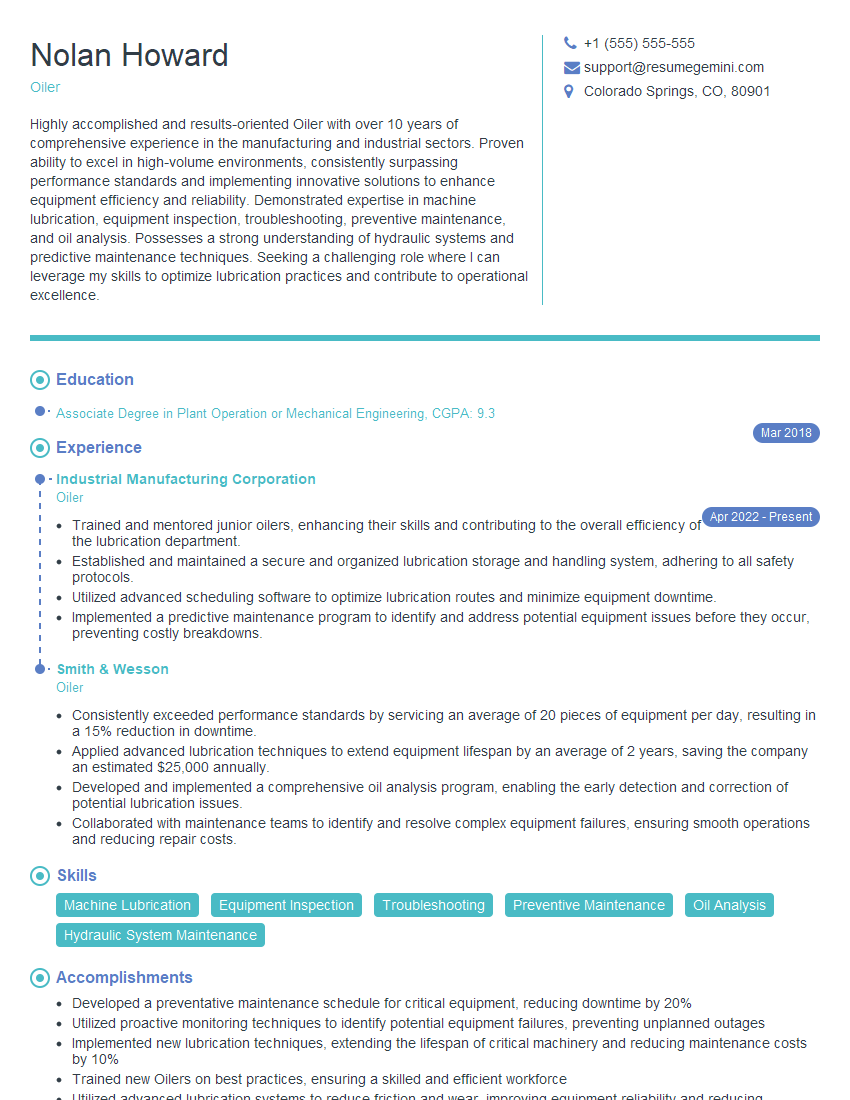

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oiler

1. Describe the role and responsibilities of an Oiler?

As an Oiler, I am responsible for maintaining and servicing machinery and equipment within a facility. My duties include lubricating moving parts, replacing filters, and monitoring equipment performance to ensure optimal operation. I also perform routine maintenance tasks, such as cleaning and inspecting machinery, and I make minor repairs and adjustments to keep equipment running smoothly.

2. What are the most important qualities for an Oiler to possess?

The most important qualities for an Oiler include attention to detail, mechanical aptitude, and a strong work ethic. Oilers must be able to work independently and as part of a team, and they should be able to handle physical work and work in a variety of environments.

3. What are the different types of lubricants used in industrial settings?

There are various types of lubricants used in industrial settings, including oils, greases, and solid lubricants. Oils are typically used for circulating systems, while greases are used for low-speed, high-load applications. Solid lubricants are used in extreme environments, such as high temperatures or vacuum environments.

4. Describe the process for changing the oil in a hydraulic system.

Changing the oil in a hydraulic system involves several steps:

- Draining the old oil from the system

- Flushing the system with new oil

- Filling the system with new oil

- Bleeding the system to remove air

5. What are the different types of bearings used in machinery?

There are different types of bearings used in machinery, including:

- Rolling element bearings (e.g., ball bearings, roller bearings)

- Plain bearings (e.g., sleeve bearings, journal bearings)

- Hydrodynamic bearings

- Magnetic bearings

6. Describe the process for aligning a conveyor belt.

Aligning a conveyor belt involves several steps:

- Checking the belt for wear or damage

- Adjusting the belt tension

- Aligning the belt pulleys

- Lubricating the belt and pulleys

7. What are the most common types of seals used in industrial equipment?

The most common types of seals used in industrial equipment include:

- Mechanical seals

- Gaskets

- O-rings

- Lip seals

8. Describe the process for replacing a V-belt.

Replacing a V-belt involves several steps:

- Releasing the tension on the old belt

- Removing the old belt

- Installing the new belt

- Adjusting the tension on the new belt

9. What are the safety precautions that should be taken when working with machinery?

When working with machinery, it is essential to follow safety precautions to avoid accidents and injuries. These precautions include:

- Wearing appropriate safety gear (e.g., gloves, safety glasses, hearing protection)

- Ensuring that machinery is properly guarded

- Locking out and tagging out machinery before performing maintenance or repairs

- Being aware of moving parts and potential hazards

10. Describe a situation where you had to troubleshoot a problem with a piece of machinery.

In my previous role, I encountered a situation where a conveyor belt was not running smoothly. I followed a systematic troubleshooting process, which involved checking the belt for wear, adjusting the tension, and lubricating the belt and pulleys. After implementing these steps, the conveyor belt started running smoothly again.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Oiler is responsible for maintaining and servicing machinery, equipment, and engines to ensure their smooth and efficient operation. Their responsibilities cover a wide range of tasks related to lubrication, inspection, and maintenance.

1. Lubrication

Oilers are primarily responsible for ensuring that all machinery and equipment are properly lubricated. This involves:

- Selecting and applying the appropriate lubricants

- Determining lubrication intervals and schedules

- Monitoring oil levels and replenishing as needed

- Inspecting and cleaning lubrication systems

- Maintaining oil storage and handling equipment

2. Inspection and Maintenance

Oilers conduct regular inspections to identify and address any potential issues or defects:

- Inspecting machinery and equipment for signs of wear, damage, or leaks

- Testing and adjusting equipment to ensure proper operation

- Identifying and repairing minor faults

- Monitoring equipment performance and identifying potential problems

- Keeping maintenance records and reporting on equipment status

3. Breakdown Management

Oilers respond promptly to equipment breakdowns and malfunctions:

- Troubleshooting and diagnosing equipment problems

- Repairing or replacing faulty components

- Restarting and testing equipment to ensure proper operation

- Documenting repairs and maintenance activities

- Coordinating with maintenance teams for major repairs

4. Safety and Compliance

Oilers place a strong emphasis on safety and regulatory compliance:

- Following all safety protocols and procedures

- Wearing appropriate personal protective equipment (PPE)

- Adhering to environmental regulations and waste disposal procedures

- Reporting any safety hazards or concerns

- Maintaining a clean and organized work area

Interview Tips

Preparing for an Oiler interview requires thorough understanding of the job responsibilities. Here are some tips to help you ace the interview:

1. Research the Company and the Industry

Familiarize yourself with the company’s history, mission, and the industry they operate in. This will demonstrate your interest in the position and understanding of the field.

- Visit the company website to learn about their products, services, and recent news.

- Research industry trends and advancements related to lubrication and machinery maintenance.

2. Highlight Your Technical Skills

Emphasize your expertise in lubrication, inspection, and equipment maintenance. Quantify your experience whenever possible, using specific examples.

- Describe specific maintenance procedures you have performed, highlighting your attention to detail and troubleshooting abilities.

- Share your knowledge of different types of lubricants and how you select the appropriate ones for various applications.

- Discuss any certifications or training programs you have completed to enhance your technical skills.

3. Demonstrate Safety Awareness

Safety is paramount for Oilers. Emphasize your commitment to following safety protocols and regulations:

- Describe your experience in adhering to safety procedures and wearing the appropriate PPE.

- Explain how you identify and report safety hazards, ensuring a safe work environment.

- Discuss any safety-related training or certifications you have obtained.

4. Showcase Your Problem-Solving Abilities

Oilers often encounter equipment breakdowns and malfunctions. Highlight your ability to diagnose problems and implement effective solutions:

- Provide examples of complex equipment issues you have resolved, demonstrating your troubleshooting skills.

- Explain your approach to problem-solving, emphasizing logical thinking and attention to detail.

- Discuss your experience working with maintenance teams to resolve major equipment issues.

5. Prepare for Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivation:

- Tell me about your experience as an Oiler.

- Describe a challenging equipment malfunction you resolved.

- Why are you interested in working for our company?

- How do you prioritize your work when faced with multiple tasks?

- What are your strengths and weaknesses as an Oiler?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Oiler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.