Are you gearing up for a career in Nozzle and Sleeve Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Nozzle and Sleeve Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

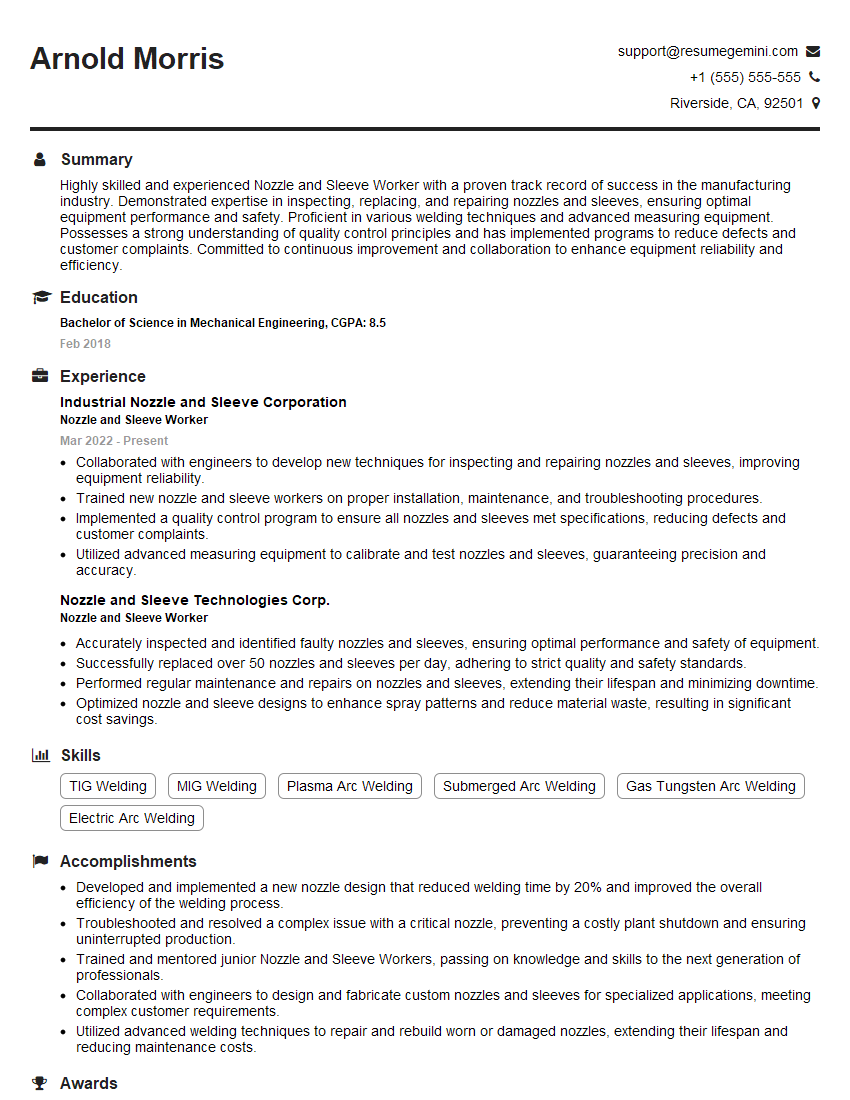

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nozzle and Sleeve Worker

1. What are the different types of nozzles and sleeves used in welding?

- Nozzles are used to direct the flow of shielding gas and protect the weld puddle from contamination.

- Sleeves are used to insulate the welding torch and protect the welder from heat and radiation.

- Some of the most common types of nozzles include the straight nozzle, the curved nozzle, and the diffuser nozzle.

- Some of the most common types of sleeves include the ceramic sleeve, the quartz sleeve, and the water-cooled sleeve.

2. How do you select the right nozzle and sleeve for a particular welding application?

The type of nozzle and sleeve used for a particular welding application will depend on a number of factors, including the type of welding process being used, the thickness of the material being welded, and the desired weld quality.

- For example, a straight nozzle is typically used for welding thin materials, while a curved nozzle is used for welding thicker materials.

- A diffuser nozzle is used for welding in windy conditions.

- A ceramic sleeve is typically used for welding at high temperatures, while a quartz sleeve is used for welding at lower temperatures.

- A water-cooled sleeve is used for welding in applications where the torch is subjected to a lot of heat.

3. What are the proper procedures for installing and removing nozzles and sleeves?

- To install a nozzle, first remove the old nozzle by unscrewing it from the torch body.

- Clean the torch body and the threads on the nozzle.

- Apply a small amount of anti-seize compound to the threads of the nozzle.

- Screw the nozzle onto the torch body and tighten it securely.

- To remove a nozzle, simply unscrew it from the torch body.

- To install a sleeve, first slide the sleeve over the torch body.

- Tighten the sleeve nut to secure the sleeve in place.

- To remove a sleeve, simply loosen the sleeve nut and slide the sleeve off the torch body.

4. What are the common problems that can occur with nozzles and sleeves, and how do you troubleshoot them?

Some of the most common problems that can occur with nozzles and sleeves include:

- Clogged nozzles

- Cracked sleeves

- Loose sleeves

- Damaged threads

To troubleshoot these problems, first inspect the nozzle or sleeve for any visible damage.

- If the nozzle is clogged, you can try to clean it with a wire brush or a pipe cleaner.

- If the sleeve is cracked, you will need to replace it.

- If the sleeve is loose, you can tighten the sleeve nut.

- If the threads are damaged, you will need to replace the nozzle or sleeve.

5. What safety precautions should be taken when working with nozzles and sleeves?

- Always wear appropriate safety gear, including gloves, eye protection, and a welding helmet.

- Make sure that the welding torch is properly grounded.

- Do not touch the nozzle or sleeve with your bare hands.

- Allow the nozzle and sleeve to cool down before handling them.

- Dispose of used nozzles and sleeves properly.

6. What are the different types of welding processes that use nozzles and sleeves?

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

- Plasma arc welding (PAW)

- Laser welding

- Electron beam welding

7. What are the benefits of using high-quality nozzles and sleeves?

- Improved weld quality

- Increased productivity

- Reduced downtime

- Lower operating costs

8. What are the latest trends in nozzle and sleeve technology?

- Nozzles and sleeves made from new materials, such as ceramics and composites

- Nozzles and sleeves with new designs, such as nozzles with built-in gas lenses

- Nozzles and sleeves with new features, such as nozzles with integrated cooling systems

9. What are the key factors to consider when choosing a nozzle and sleeve supplier?

- Quality of products

- Price

- Delivery time

- Customer service

10. What are the most common mistakes that welders make when using nozzles and sleeves?

- Not using the right nozzle or sleeve for the job

- Not installing the nozzle or sleeve properly

- Not maintaining the nozzle or sleeve properly

- Not replacing the nozzle or sleeve when it is worn out

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nozzle and Sleeve Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nozzle and Sleeve Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Nozzle and Sleeve Worker plays a crucial role in ensuring the efficient and effective operation of nozzles and sleeves within an industrial setting. Their primary duties and responsibilities encompass:

1. Nozzle Installation and Maintenance

Performing installation, replacement, and maintenance of nozzles and sleeves to ensure optimal system performance. Coordinating with other technicians and engineers to plan and execute scheduled and preventive maintenance.

2. Sleeve Operation and Monitoring

Operating and monitoring sleeves to control the flow of various materials or fluids. Ensuring sleeves are functioning correctly and making necessary adjustments to maintain flow rates and pressures within specified parameters.

3. Quality Control and Troubleshooting

Conducting regular inspections of nozzles and sleeves to identify potential issues. Troubleshooting and resolving operational problems related to nozzles and sleeves promptly and effectively to minimize downtime.

4. Safety and Compliance

Adhering to all safety regulations and guidelines. Wearing appropriate protective gear and using safe work practices to prevent accidents and injuries. Maintaining a clean and organized work area.

Interview Tips

Preparing thoroughly for an interview as a Nozzle and Sleeve Worker can significantly increase your chances of success. Here are some practical tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s mission, values, and recent developments. Research the industry trends and current best practices to demonstrate your understanding of the field.

2. Review Job Responsibilities and Qualifications

Carefully review the job description to identify the key responsibilities and qualifications required for the role. Highlight how your skills and experiences align with these requirements, providing specific examples whenever possible.

3. Prepare for Technical Questions

Technical questions related to nozzles and sleeves are likely to be asked. Be prepared to discuss different types of nozzles and sleeves, their functions, and common troubleshooting techniques. Demonstrating your technical knowledge and expertise will impress the interviewer.

4. Showcase Your Safety Consciousness

Emphasize your commitment to safety by outlining your adherence to safety protocols and regulations. Discuss your experience in wearing appropriate protective gear and maintaining a safe work environment.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions related to the company culture, growth opportunities, or specific aspects of the role that you are particularly interested in.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nozzle and Sleeve Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.