Are you gearing up for an interview for a Polishing Wheel Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Polishing Wheel Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

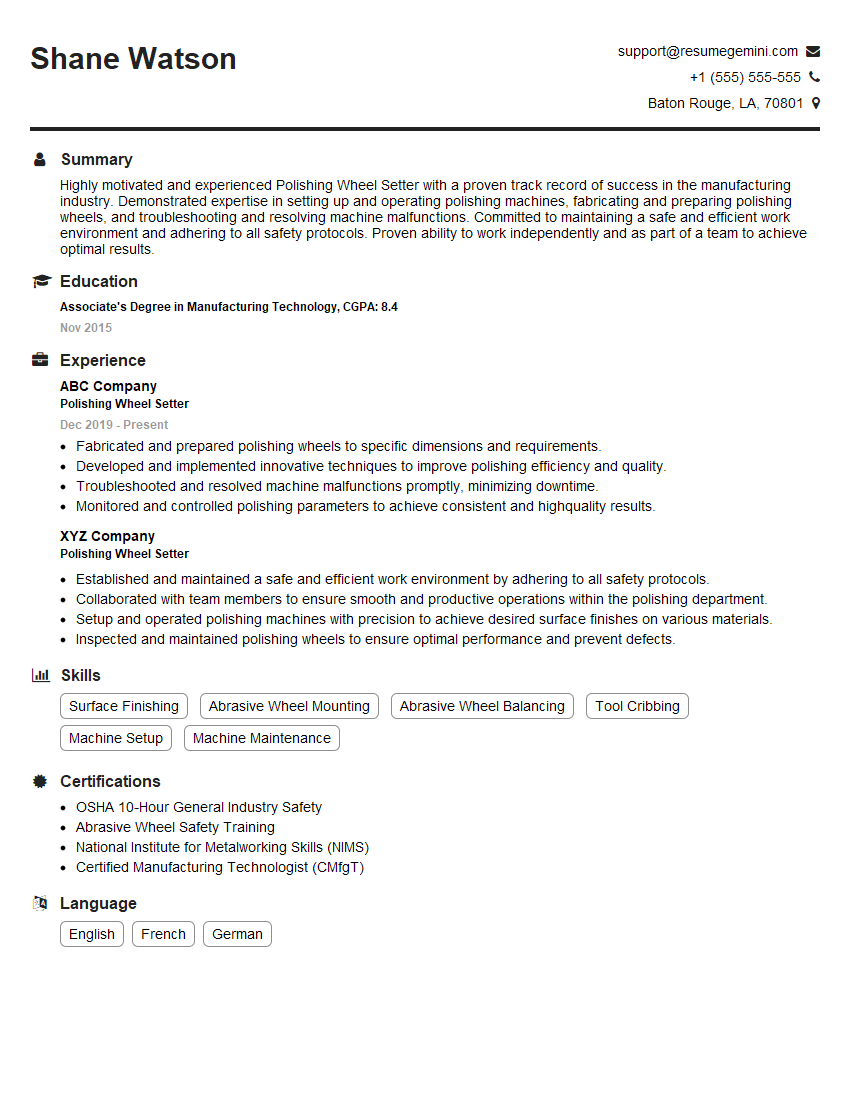

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Polishing Wheel Setter

1. What are the different types of polishing wheels and their applications?

- Polishing wheels made of Woven cotton fabrics are used for ferrous and non-ferrous metals, glass, ceramics, rubber and plastics.

- Polishing wheels made of Cloth are Good for fine polishing of metals such as sterling silver.

2. How do you select the appropriate polishing wheel for a particular application?

Factors to Consider:

- The material being polished

- Surface Finish

- Size and shape of the workpiece

- Speed and pressure of the polishing machine

Wheel Selection:

- Harder wheels for rough polishing

- Softer wheels for fine polishing

- Larger wheels for larger surfaces

- Smaller wheels for smaller surfaces or intricate shapes

3. What are the safety precautions that should be taken when using polishing wheels?

- Wear appropriate safety gear (gloves, eye protection, dust mask)

- Ensure the polishing wheel is properly balanced and mounted

- Use the correct wheel speed and pressure

- Keep the work area clean and free of debris

- Be aware of potential hazards such as sparks, dust, and flying particles

4. How do you maintain and clean polishing wheels?

- Clean wheels regularly with a brush or compressed air to remove debris

- Dress the wheels periodically to restore their shape and surface texture

- Replace wheels when they become worn or damaged

5. What is the difference between polishing and buffing?

- Polishing removes surface imperfections and produces a smooth finish

- Buffing produces a high-shine finish by removing fine scratches and imperfections

6. What are the different types of polishing compounds and their uses?

- Coarse compounds for removing heavy scratches and imperfections

- Medium compounds for general-purpose polishing

- Fine compounds for producing a high-shine finish

- Specialty compounds for specific materials or applications (e.g., metal, plastic, glass)

7. How do you troubleshoot common problems encountered when using polishing wheels?

Problem: Wheel is not polishing effectively

Possible Causes:

- Incorrect wheel selection

- Worn or damaged wheel

- Incorrect polishing compound

- Insufficient pressure or speed

Problem: Wheel is causing excessive vibration

Possible Causes:

- Wheel is unbalanced

- Polishing machine is faulty

- Workpiece is not properly secured

8. What are the challenges and rewards of being a Polishing Wheel Setter?

Challenges:

- Repetitive and physically demanding work

- Exposure to dust, fumes, and noise

- Working with potentially hazardous materials

Rewards:

- Satisfaction of seeing the results of your work

- Opportunities for advancement within the industry

- Stable income and benefits

9. How do you stay up-to-date on the latest polishing techniques and technologies?

- Attend industry conferences and workshops

- Read trade publications and online resources

- Consult with manufacturers and suppliers

- Experiment with different techniques and compounds

10. Why are you interested in this Polishing Wheel Setter position?

- Passion for polishing and finishing

- Strong attention to detail

- Ability to work independently and as part of a team

- Experience in a related field or strong technical aptitude

- Commitment to safety and quality

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Polishing Wheel Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Polishing Wheel Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Polishing Wheel Setters are responsible for setting up, operating, and maintaining polishing wheels used in the manufacturing process. They ensure that the wheels are set up correctly to produce a high-quality finish on the product being polished.

1. Set up and adjust polishing wheels

Polishing Wheel Setters are responsible for setting up and adjusting polishing wheels to the correct specifications. This includes mounting the wheel on the spindle, adjusting the speed and pressure, and setting the angle of the wheel to the workpiece.

- Mount the wheel on the spindle

- Adjust the speed and pressure

- Set the angle of the wheel to the workpiece

2. Operate polishing wheels safely and efficiently

Polishing Wheel Setters are responsible for operating polishing wheels safely and efficiently. This includes following all safety procedures, wearing the appropriate personal protective equipment, and using the correct techniques to polish the workpiece.

- Follow all safety procedures

- Wear the appropriate personal protective equipment

- Use the correct techniques to polish the workpiece

3. Maintain polishing wheels in good working condition

Polishing Wheel Setters are responsible for maintaining polishing wheels in good working condition. This includes cleaning the wheels, replacing worn or damaged parts, and lubricating the bearings.

- Clean the wheels

- Replace worn or damaged parts

- Lubricate the bearings

4. Inspect and test polished workpieces

Polishing Wheel Setters are responsible for inspecting and testing polished workpieces to ensure that they meet the required specifications. This includes checking the surface finish, dimensions, and other quality characteristics.

- Check the surface finish

- Check the dimensions

- Check other quality characteristics

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before you go on an interview, it’s important to do your research on the company and the position you’re applying for. This will help you to understand the company’s culture, values, and goals. You’ll also be able to learn more about the specific requirements of the position.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer questions

- Be specific and provide examples

- Practice your answers out loud

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This will show the interviewer that you’re respectful of their time.

- Dress in business attire

- Be clean and well-groomed

- Arrive on time or early

4. Be yourself and be confident

The most important thing to remember during an interview is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

- Be honest and authentic

- Be confident in your abilities

- Let your personality shine through

Next Step:

Now that you’re armed with the knowledge of Polishing Wheel Setter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Polishing Wheel Setter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini