Are you gearing up for a career in Pump Oiler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Pump Oiler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

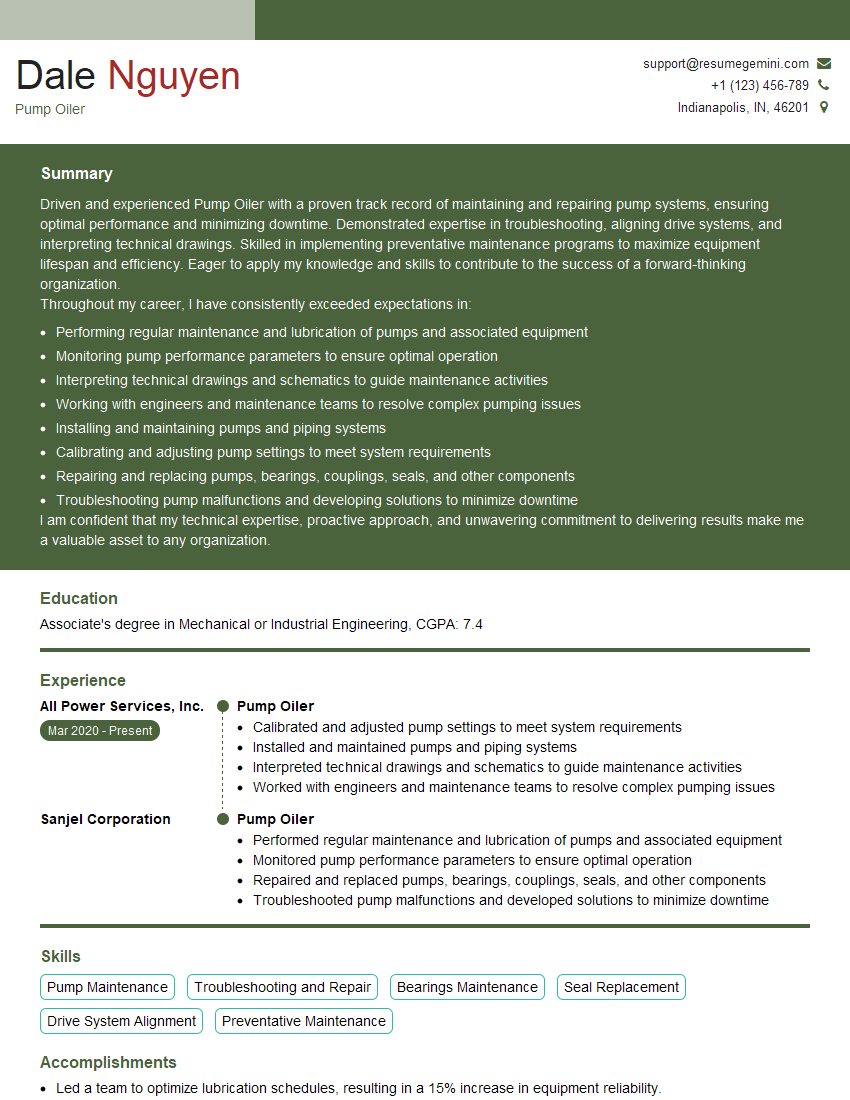

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pump Oiler

1. What are the key responsibilities of a Pump Oiler?

The key responsibilities of a Pump Oiler typically include:

- Lubricating pumps, motors, and other machinery to ensure smooth and efficient operation

- Inspecting and monitoring pumps for any signs of wear, damage, or leaks

- Replacing worn or damaged parts as needed to maintain optimal pump performance

- Maintaining accurate records of lubrication schedules and maintenance activities

- Assisting with pump repairs and troubleshooting as required

2. What types of pumps have you worked on in the past?

Centrifugal Pumps

- Experience in maintaining and servicing centrifugal pumps

- Understanding of centrifugal pump design and operation

Positive Displacement Pumps

- Experience in maintaining and servicing positive displacement pumps

- Understanding of positive displacement pump design and operation

3. How do you determine the appropriate lubricant for a specific pump?

The appropriate lubricant for a specific pump is typically determined based on the following factors:

- Pump type and design

- Operating conditions (temperature, pressure, speed)

- Manufacturer’s recommendations

- Industry best practices

4. What are some common causes of pump failure?

Some common causes of pump failure include:

- Improper lubrication

- Excessive wear and tear

- Corrosion

- Mechanical damage

- Electrical problems

5. How do you troubleshoot a pump that is not functioning properly?

To troubleshoot a pump that is not functioning properly, I would typically follow these steps:

- Check the power supply to the pump

- Inspect the pump for any visible signs of damage

- Check the pump’s lubrication level and condition

- Listen for any unusual noises or vibrations

- Review the pump’s maintenance history

6. What are some preventive maintenance tasks that can be performed to extend the life of a pump?

Some preventive maintenance tasks that can be performed to extend the life of a pump include:

- Regular lubrication

- Periodic inspections

- Filter cleaning or replacement

- Tightening of loose connections

- Monitoring of vibration and temperature levels

7. How do you stay up-to-date on the latest pump maintenance techniques?

To stay up-to-date on the latest pump maintenance techniques, I typically:

- Attend industry conferences and workshops

- Read trade publications and articles

- Consult with pump manufacturers and experts

8. Are you familiar with any specific pump maintenance software or tools?

Yes, I am familiar with several pump maintenance software and tools, including:

- Pump Manager by SKF

- Pumpscare by Fluke

- PumpWatch by Hach

9. What is your experience with vibration analysis?

I have experience in vibration analysis and have used it to identify and diagnose problems with pumps. I have used vibration analysis to:

- Detect bearing wear

- Identify misalignment

- Diagnose pump cavitation

10. Are you comfortable working with electrical components?

Yes, I am comfortable working with electrical components and have experience in troubleshooting and repairing electrical problems with pumps. I am familiar with electrical safety procedures and have a good understanding of electrical circuits.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pump Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pump Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pump Oilers work at various industries such as manufacturing, construction and more. They are usually responsible for lubricating moving parts of machinery and equipment to reduce friction and wear.

1. Lubrication and Maintenance

Primary responsibility of Pump Oilers is to lubricate machinery and equipment using oil cans, grease guns, or oilers. They also monitor and maintain lubrication systems, such as centralized lubrication systems.

- Lubricate bearings, gears, shafts, and other moving parts of machinery and equipment.

- Monitor and maintain lubrication systems, such as centralized lubrication systems.

- Inspect equipment for signs of wear or damage, and report any problems to supervisors.

2. Troubleshooting and Repair

Pump Oilers may troubleshoot and repair minor equipment problems. They may also assist with more complex repairs, such as replacing bearings or seals.

- Troubleshoot and repair minor equipment problems.

- Assist with more complex repairs, such as replacing bearings or seals.

- Maintain a clean and safe work area.

3. Safety and Compliance

Pump Oilers must follow all safety procedures and regulations. They must also be aware of the potential hazards of their work, such as working with chemicals and hazardous materials.

- Follow all safety procedures and regulations.

- Be aware of the potential hazards of their work, such as working with chemicals and hazardous materials.

- Use personal protective equipment (PPE), such as gloves, safety glasses, and respirators, when necessary.

Interview Tips

Preparing for an interview for a Pump Oiler position can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are some tips to help you prepare:

1. Research the Company and the Position

Take some time to learn about the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and tailor your answers to the interviewer’s questions accordingly.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work for the company

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise way.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions.

- Be prepared to talk about your skills and experience.

- Be enthusiastic and positive.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and shoes, and avoiding casual clothing such as jeans and t-shirts.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Avoid wearing strong scents or perfumes.

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Aim to arrive at the interview location 10-15 minutes early so that you have time to relax and collect your thoughts before the interview begins.

- Plan your route in advance.

- Allow for extra time in case of traffic delays.

- If you are running late, call or email the interviewer to let them know.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pump Oiler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.