Are you gearing up for a career in Rubber and Plastics Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rubber and Plastics Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

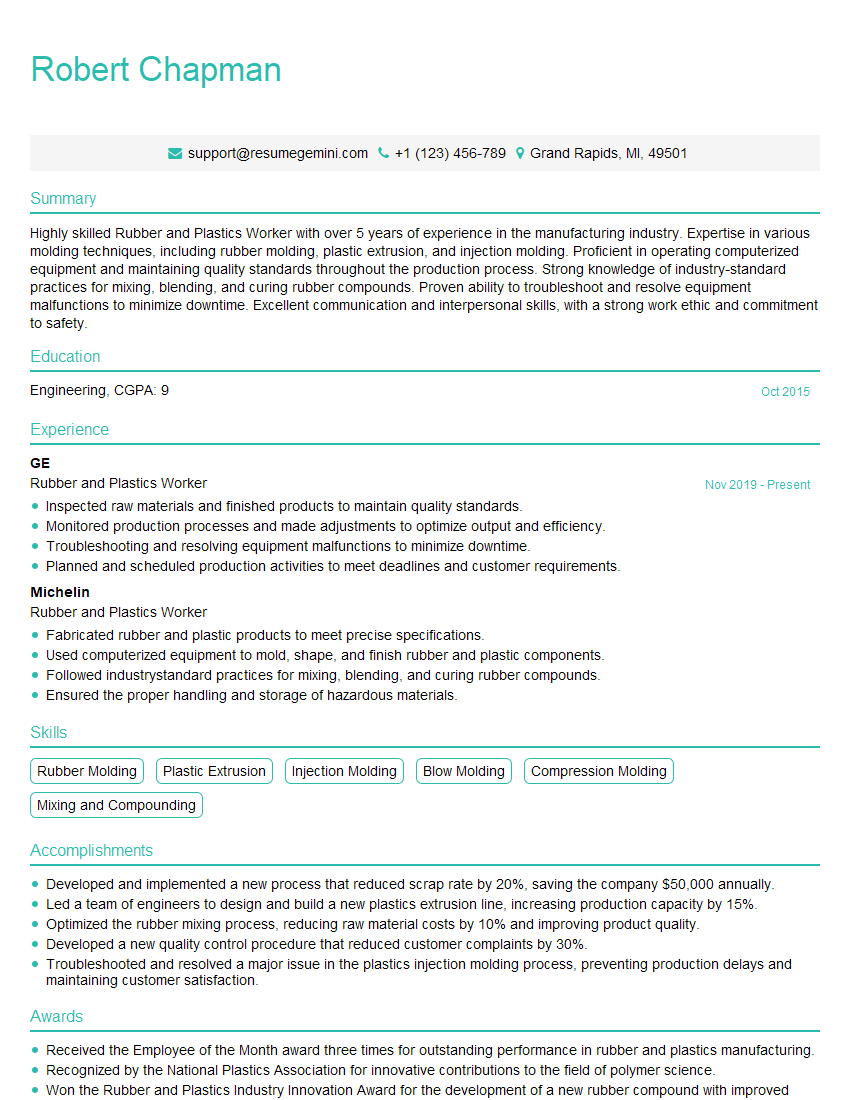

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber and Plastics Worker

1. Describe the process of rubber vulcanization.

Vulcanization is a chemical process that transforms raw rubber into a more durable and resilient material. It involves heating rubber with sulfur or other vulcanizing agents to create cross-links between the rubber molecules.

- The process begins by mixing the raw rubber with sulfur and other additives.

- The mixture is then heated under pressure, which causes the sulfur atoms to form bonds with the rubber molecules.

- This creates a cross-linked network structure that gives vulcanized rubber its superior strength, elasticity, and resistance to heat and chemicals.

2. What are the different types of plastics and their properties?

There are numerous types of plastics, each with unique properties that make them suitable for specific applications.

Thermoplastics:

- Can be melted and reshaped multiple times without undergoing chemical changes.

- Examples: polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC).

Thermosetting plastics:

- Undergo irreversible chemical changes when heated, making them unsuitable for re-melting or reshaping.

- Examples: epoxy resins, polyester resins, phenolic resins.

Elastomers:

- Exhibit rubber-like properties, such as high elasticity and flexibility.

- Examples: natural rubber, synthetic rubber (SBR), silicone rubber.

3. Explain the principles of injection molding and its applications.

Injection molding is a high-pressure forming process used to produce plastic parts with complex shapes and intricate details.

- Molten plastic is injected into a mold cavity under high pressure.

- The plastic solidifies and conforms to the shape of the mold.

- The mold is then opened, and the finished part is ejected.

Injection molding is used in various industries, including automotive, electronics, and medical devices.

4. Describe the role of quality control in rubber and plastics manufacturing.

Quality control is crucial in rubber and plastics manufacturing to ensure the production of high-quality products that meet customer specifications and industry standards.

- Inspecting raw materials to ensure they meet required properties.

- Monitoring production processes to identify and minimize defects.

- Testing finished products to verify their compliance with design and performance criteria.

- Identifying and implementing corrective actions to improve product quality.

5. Discuss the safety precautions that must be observed when working with rubber and plastics.

Working with rubber and plastics involves potential hazards that require adherence to strict safety precautions.

- Proper ventilation is essential to prevent exposure to harmful fumes and dust.

- Protective clothing, including gloves, masks, and goggles, should be worn to minimize skin and eye contact with chemicals.

- Proper handling and storage of chemicals to avoid spills and accidents.

- Training on emergency procedures and the use of safety equipment.

6. Explain the importance of material testing in rubber and plastics manufacturing.

Material testing plays a vital role in the development and production of rubber and plastic products.

- Evaluates the physical and chemical properties of materials to ensure they meet design specifications.

- Identifies any defects or impurities that could impact product performance.

- Helps optimize production processes by providing insights into material behavior.

- Facilitates product development by assessing the suitability of materials for specific applications.

7. Describe the different methods used for mixing and compounding rubber and plastics.

Mixing and compounding are crucial processes in rubber and plastics manufacturing, as they determine the properties of the final product.

- Internal mixers: Used for blending and mixing ingredients within a closed chamber.

- Banbury mixers: High-intensity mixers that generate frictional heat to facilitate mixing.

- Roll mills: Used for mixing and refining rubber compounds by passing them between heated rollers.

- Extruders: Continuous mixing and shaping devices that combine and homogenize materials.

8. Explain the concept of part design for injection molding and its impact on product quality.

Part design is critical in injection molding as it influences the quality and functionality of the final product.

- Design should consider factors such as part geometry, material selection, and moldability.

- Proper design minimizes stresses, warpage, and defects during molding.

- Optimizing part design can enhance product performance, reduce production costs, and improve overall quality.

9. Discuss the factors that affect the strength and durability of rubber and plastics.

The strength and durability of rubber and plastics are influenced by various factors, including:

- Material composition and properties.

- Processing conditions and techniques.

- Environmental factors such as temperature, UV radiation, and chemicals.

- Design and geometry of the product.

- Proper maintenance and storage practices.

10. Describe the techniques used for troubleshooting common defects in rubber and plastics products.

Troubleshooting defects in rubber and plastics products is essential to maintain product quality and customer satisfaction.

- Visual inspection: Identifying surface defects, cracks, or imperfections.

- Dimensional measurement: Verifying dimensions and tolerances using calipers, gauges, or coordinate measuring machines.

- Material testing: Evaluating material properties using tensile, flexural, or impact tests.

- Process analysis: Reviewing production processes to identify potential sources of defects.

- Root cause analysis: Conducting investigations to determine the underlying causes of defects and implementing corrective actions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber and Plastics Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber and Plastics Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for a Rubber and Plastics Worker

Rubber and Plastics Workers are responsible for a variety of tasks in the manufacturing process of rubber and plastics products. Their key responsibilities include:1. Operating and monitoring machinery

Rubber and Plastics Workers operate and monitor a variety of machinery, including injection molding machines, extruders, and molding presses. They are responsible for ensuring that the machinery is running properly and that the products are produced to the correct specifications.

2. Preparing and mixing materials

Rubber and Plastics Workers prepare and mix a variety of materials, including rubber, plastics, and additives. They must carefully follow the recipes and instructions to ensure that the final product meets the desired specifications.

3. Inspecting and testing products

Rubber and Plastics Workers inspect and test the finished products to ensure that they meet the required quality standards. They may also be responsible for testing the raw materials to ensure that they meet the required specifications.

4. Maintaining and repairing equipment

Rubber and Plastics Workers are responsible for maintaining and repairing the equipment used in the manufacturing process. They must be able to identify and troubleshoot problems and make repairs as needed.

Interview Tips for Rubber and Plastics Workers

Preparing for an interview for a Rubber and Plastics Worker position can help you make a great impression and increase your chances of getting the job. Here are a few tips to help you prepare:1. Research the company and the position

Before you go to the interview, be sure to research the company and the specific position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is a good idea to practice answering these questions in advance so that you can deliver your answers confidently and smoothly.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about your work history and the specific skills that you have that would make you a good fit for the job.

4. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire and making sure that you are well-groomed.

5. Be confident and enthusiastic

Confidence and enthusiasm are contagious, so make sure that you project these qualities during your interview. The interviewer will be more likely to be impressed with you if you are confident in your abilities and enthusiastic about the position.

Next Step:

Now that you’re armed with the knowledge of Rubber and Plastics Worker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rubber and Plastics Worker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini