Are you gearing up for a career in Shafting Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Shafting Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

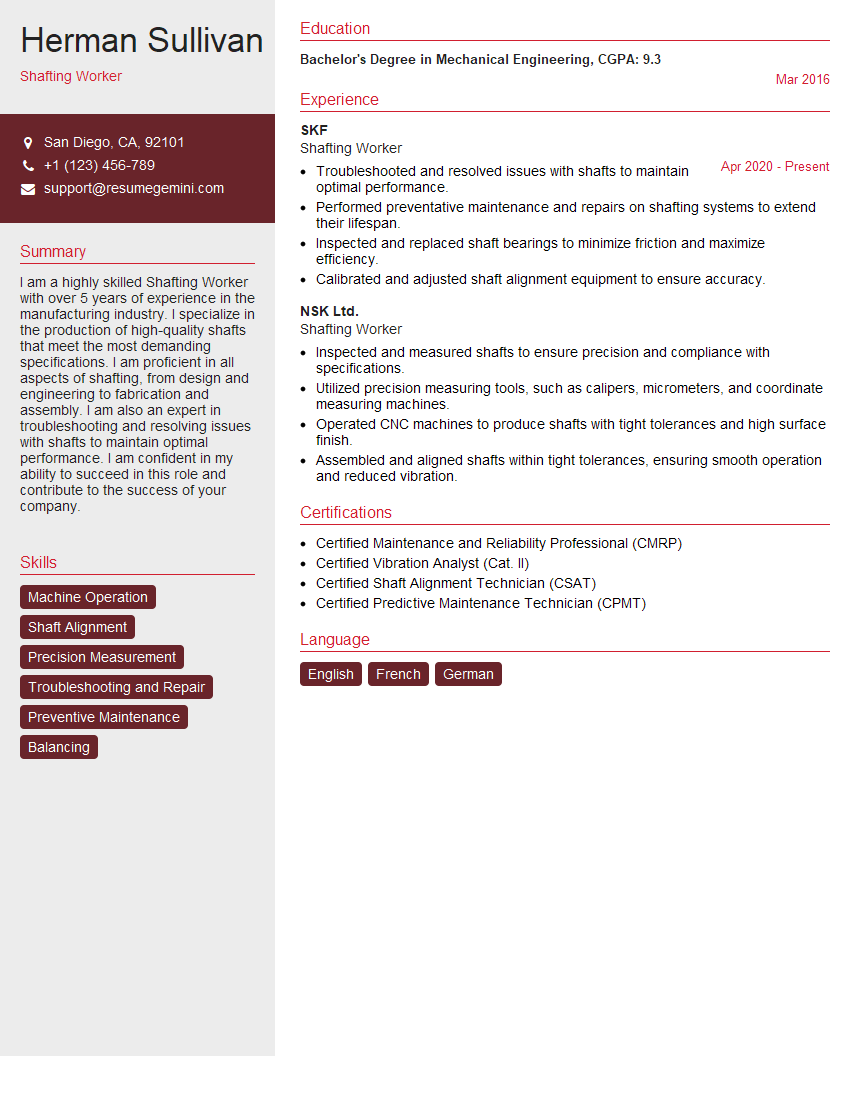

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Shafting Worker

1. Describe the different types of shafts and their applications?

There are several types of shafts, each with its own specific applications. Some of the most common types include:

- Solid shafts: These shafts are made from a single piece of metal and are the most common type of shaft. They are used in applications where strength and rigidity are required.

- Hollow shafts: These shafts are made from a tube of metal and are lighter than solid shafts. They are often used in applications where weight is a concern, such as in aircraft and racing cars.

- Stepped shafts: These shafts have different diameters along their length. They are used in applications where different parts of the shaft need to rotate at different speeds or torques.

- Flexible shafts: These shafts are made from a flexible material, such as rubber or plastic. They are used in applications where the shaft needs to be able to bend or flex, such as in power tools and medical devices.

2. What are the different types of materials used to make shafts?

- Steel: Steel is the most common material used to make shafts. It is strong, durable, and relatively inexpensive.

- Stainless steel: Stainless steel is a corrosion-resistant alloy of steel. It is more expensive than steel, but it is more resistant to rust and other forms of corrosion.

- Aluminum: Aluminum is a lightweight metal that is often used in shafts for aircraft and other applications where weight is a concern.

- Titanium: Titanium is a strong, lightweight metal that is often used in shafts for high-performance applications, such as in racing cars and aircraft.

- Composite materials: Composite materials are made from a combination of different materials, such as carbon fiber and fiberglass. They are lightweight and strong, and they can be tailored to meet the specific requirements of an application.

3. What are the different methods used to manufacture shafts?

- Cold forming: Cold forming is a process in which metal is shaped at room temperature using a press or other forming tool. This process is often used to make small, simple shafts.

- Hot forming: Hot forming is a process in which metal is heated and then shaped using a press or other forming tool. This process is often used to make large, complex shafts.

- Casting: Casting is a process in which molten metal is poured into a mold and allowed to cool and solidify. This process is often used to make shafts with complex shapes.

- Forging: Forging is a process in which metal is heated and then hammered or pressed into shape. This process is often used to make shafts with high strength and durability.

4. What are the different types of surface treatments that can be applied to shafts?

- Plating: Plating is a process in which a thin layer of metal is deposited on the surface of a shaft. This process can be used to improve the corrosion resistance, wear resistance, and appearance of a shaft.

- Anodizing: Anodizing is a process in which the surface of a shaft is converted into a hard, wear-resistant oxide layer. This process can be used to improve the corrosion resistance and wear resistance of a shaft.

- Painting: Painting is a process in which a thin layer of paint is applied to the surface of a shaft. This process can be used to improve the appearance of a shaft and to protect it from corrosion.

5. What are the different types of bearings that can be used with shafts?

- Rolling bearings: Rolling bearings use rolling elements, such as balls or rollers, to support a shaft. They are the most common type of bearing and are used in a wide variety of applications.

- Plain bearings: Plain bearings use a sliding contact between the shaft and the bearing surface. They are less common than rolling bearings, but they are often used in applications where low friction is required.

6. What are the different factors that need to be considered when selecting a shaft?

- Load: The load that the shaft will be subjected to is the most important factor to consider when selecting a shaft. The shaft must be strong enough to withstand the load without failing.

- Speed: The speed at which the shaft will rotate is also an important factor to consider. The shaft must be able to rotate at the required speed without exceeding its critical speed.

- Environment: The environment in which the shaft will be used is also an important factor to consider. The shaft must be able to withstand the environmental conditions without corroding or failing.

7. What are the different types of shaft failures?

- Fatigue failure: Fatigue failure occurs when a shaft is subjected to repeated loading and unloading. This type of failure can occur even if the load is below the yield strength of the shaft.

- Torsional failure: Torsional failure occurs when a shaft is subjected to a twisting force. This type of failure can occur if the shaft is not strong enough to withstand the twisting force.

- Bending failure: Bending failure occurs when a shaft is subjected to a bending force. This type of failure can occur if the shaft is not strong enough to withstand the bending force.

8. What are the different methods used to prevent shaft failures?

- Proper design: The shaft must be properly designed to withstand the loads and stresses that it will be subjected to.

- Proper materials selection: The shaft must be made from a material that is strong enough to withstand the loads and stresses that it will be subjected to.

- Proper manufacturing: The shaft must be manufactured using a process that ensures that the shaft is free from defects.

- Proper maintenance: The shaft must be properly maintained to ensure that it remains in good condition.

9. What are the different types of shaft couplings?

- Rigid couplings: Rigid couplings connect two shafts together without allowing any relative movement between them.

- Flexible couplings: Flexible couplings connect two shafts together while allowing some relative movement between them. This type of coupling is used to compensate for misalignment between the shafts.

10. What are the different factors that need to be considered when selecting a shaft coupling?

- Type of shaft: The type of shaft that the coupling will be used with is the most important factor to consider when selecting a coupling.

- Load: The load that the coupling will be subjected to is also an important factor to consider. The coupling must be strong enough to withstand the load without failing.

- Speed: The speed at which the coupling will rotate is also an important factor to consider. The coupling must be able to rotate at the required speed without exceeding its critical speed.

- Environment: The environment in which the coupling will be used is also an important factor to consider. The coupling must be able to withstand the environmental conditions without corroding or failing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Shafting Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Shafting Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Shafting Workers play a crucial role in maintaining the smooth operation of a plant by ensuring the proper alignment, installation, and repair of shafts, bearings, and other rotating components.

1. Shaft Installation and Alignment

Installing and aligning shafts accurately is essential for the efficient operation of machinery. Shafting Workers are responsible for:

- Calculating and verifying shaft alignments using precision tools.

- Installing and securing shafts according to specifications.

- Adjusting and aligning couplings to ensure proper transmission of power.

2. Bearing Maintenance and Replacement

Bearings are critical components that support and reduce friction in shafts. Shafting Workers are responsible for:

- Inspecting bearings for wear, damage, and proper lubrication.

- Disassembling and replacing bearings as needed.

- Ensuring correct bearing installation and alignment.

3. Shaft Repair and Fabrication

Shafting Workers may be required to repair or fabricate shafts as needed.

- Inspecting shafts for damage or defects.

- Repairing shafts using welding, machining, or other techniques.

- Fabricating new shafts according to specifications.

4. Equipment Troubleshooting and Maintenance

Shafting Workers are often involved in troubleshooting and maintaining equipment related to shafts.

- Identifying and resolving issues with shafts, bearings, and related components.

- Performing routine maintenance and inspections.

- Maintaining a clean and organized work area.

Interview Tips

Preparing thoroughly for a Shafting Worker interview can significantly increase your chances of success.

1. Research the Company and Position

Familiarize yourself with the company’s history, industry, and current projects. Research the specific job description and identify the key responsibilities and qualifications required.

2. Practice Your Answers

Prepare thoughtful answers to common interview questions, such as:

- Tell me about your experience with shaft installation and alignment.

- Describe a time when you successfully troubleshoot a shaft-related problem.

- How do you ensure the accuracy of your work when installing and aligning shafts?

3. Highlight Your Skills and Experience

Emphasize your technical skills in shaft alignment, bearing maintenance, and repair. Showcase your experience in troubleshooting and maintaining rotating equipment.

4. Demonstrate Your Attention to Detail

Shafting Workers must be meticulous and pay close attention to detail. Highlight your ability to work precisely and follow instructions carefully.

5. Dress Professionally and Be Punctual

Make a good impression by dressing professionally and arriving for your interview on time. This shows respect for the interviewer and the company.

6. Ask Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. This is also an opportunity to clarify any details and learn more about the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Shafting Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.