Are you gearing up for a career in Turbo Generator Oiler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Turbo Generator Oiler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

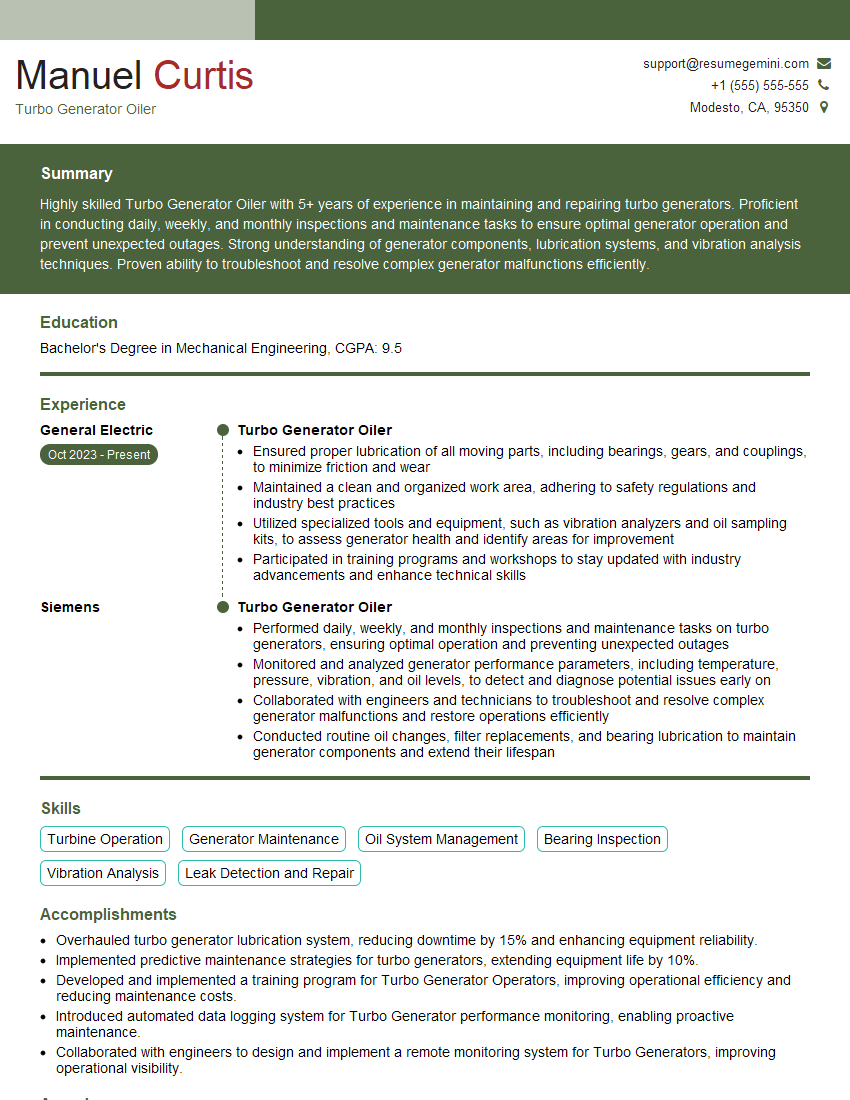

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Turbo Generator Oiler

1. Describe the role and responsibilities of a Turbo Generator Oiler?

Sample answer

- Monitor and maintain oil levels in the turbo generator system to ensure smooth operation.

- Inspect and lubricate bearings, gears, and other mechanical components to prevent wear and tear.

- Troubleshoot and resolve any oil-related issues that may arise within the system.

- Adhere to safety protocols and maintain a clean and organized work environment.

- Maintain accurate records of oil levels, inspections, and maintenance tasks performed.

2. Explain the importance of proper oil circulation in a turbo generator system?

Efficiency and performance

- Adequate oil circulation reduces friction, allowing the generator to operate more efficiently.

- Proper lubrication prevents overheating and premature wear, extending the lifespan of the equipment.

Cooling

- Oil circulation carries away heat generated by the generator’s components, preventing damage.

Protection

- Oil forms a protective layer on metal surfaces, preventing corrosion and contamination.

3. Describe the different types of oils used in turbo generators and their specific purposes?

Sample answer

- Turbine oil: High-temperature, oxidation-resistant oil used to lubricate turbine bearings.

- Generator oil: Non-conductive oil used to lubricate generator bearings and prevent electrical faults.

- Gear oil: Heavy-duty oil designed to withstand high loads and protect gears from wear.

- Hydraulic oil: Used in hydraulic systems to transmit power and actuate components.

4. Explain the steps involved in servicing a turbo generator lubrication system?

Sample answer

- Drain the old oil from the system.

- Replace the oil filter.

- Fill the system with new oil according to the manufacturer’s specifications.

- Check oil levels and ensure proper circulation.

- Clean and inspect the lubrication system components, such as oil pumps and lines.

5. How do you ensure the quality of oil in a turbo generator system?

Sample answer

- Regularly monitor oil levels and condition using dipsticks or oil level gauges.

- Perform oil analysis to check for contaminants, viscosity, and other indicators of degradation.

- Replace the oil and filter according to the manufacturer’s recommended intervals or when oil analysis indicates a need for replacement.

6. Describe the safety precautions to be taken while working with turbo generators?

Sample answer

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Follow lockout/tagout procedures to isolate the system before performing maintenance.

- Be aware of rotating equipment and avoid loose clothing or jewelry.

- Never work on live electrical components.

- Handle oils and lubricants with care to prevent spills and contamination.

7. What types of maintenance tasks are typically performed on turbo generators and how often?

Sample answer

- Daily: Monitor oil levels, check for leaks, and perform visual inspections.

- Weekly: Oil analysis, filter changes, and cleaning of components.

- Monthly: Major inspections, including vibration analysis and electrical testing.

- Annually: Overhaul of the turbo generator, including replacement of bearings, seals, and gaskets.

8. How would you troubleshoot a turbo generator that is experiencing excessive oil consumption?

Sample answer

- Check oil levels and ensure proper lubrication of all components.

- Inspect for leaks in the oil system, including hoses, seals, and gaskets.

- Examine the oil filter for clogging or contamination.

- Analyze the oil condition to identify any signs of degradation or contamination.

- Consult the manufacturer’s manuals for specific troubleshooting guidelines.

9. How do you handle emergencies involving turbo generators, such as oil leaks or fires?

Sample answer

- Instantly isolate the system and shut down the generator.

- Notify the appropriate personnel, such as the supervisor and safety team.

- Assess the situation and implement emergency response procedures.

- Contain any oil leaks or extinguish any fires using appropriate methods.

- Follow established safety protocols and ensure the safety of personnel.

10. What are the latest trends and advancements in turbo generator technology that you are aware of?

Sample answer

- Increased use of digital monitoring and control systems to improve efficiency and reliability.

- Development of new oil formulations with enhanced performance and longevity.

- Integration of renewable energy sources, such as solar and wind, into turbo generator systems.

- Research on hydrogen-fueled turbo generators for reduced emissions and improved sustainability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Turbo Generator Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Turbo Generator Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Turbo Generator Oiler plays a crucial role in ensuring the smooth and efficient operation of turbo generators in power plants.

1. Lubrication and Maintenance

Lubricates and maintains turbo generators to prevent wear and tear, ensuring optimal performance and longevity.

- Monitors oil levels and replenishes as needed

- Checks and adjusts oil pressure

- Replaces oil filters and performs oil changes

2. Inspections and Troubleshooting

Inspects and troubleshoots turbo generators to identify and resolve potential issues promptly.

- Inspects generator components for signs of wear or damage

- Troubleshoots and repairs minor electrical and mechanical issues

- Reports major issues to supervisors for attention

3. Operation and Monitoring

Operates and monitors turbo generators to ensure continuous power generation.

- Starts and stops generators as per instructions

- Monitors generator parameters such as temperature, pressure, and voltage

- Adjusts generator settings to optimize performance

4. Safety and Compliance

Adheres to safety regulations and operating procedures to ensure a safe and compliant work environment.

- Wears appropriate safety gear

- Follows established maintenance and operating protocols

- Reports any hazardous conditions or unsafe practices

Interview Preparation Tips

To ace an interview for a Turbo Generator Oiler position, follow these preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific requirements for the Turbo Generator Oiler role.

- Visit the company’s website and read about their products, services, and mission.

- Review the job description carefully and identify the key responsibilities and qualifications.

2. Practice Common Interview Questions

Prepare for frequently asked interview questions related to your experience, skills, and knowledge.

- Tell me about your experience maintaining and troubleshooting turbo generators.

- How do you ensure the safe and efficient operation of generators?

- Describe a time when you successfully resolved a major generator issue.

3. Highlight Relevant Skills and Competencies

Emphasize your technical skills, problem-solving abilities, and experience in a power plant environment.

- Lubrication and maintenance techniques

- Electrical and mechanical troubleshooting

- Safety and compliance knowledge

- Ability to work independently and as part of a team

- Strong attention to detail

4. Prepare Questions for the Interviewer

Asking well-thought-out questions demonstrates your interest and engagement in the position.

- Inquire about the specific challenges and opportunities of the Turbo Generator Oiler role within the company.

- Ask about the training and support provided for the position.

- Express your enthusiasm for the company and how your skills and experience align with their needs.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Turbo Generator Oiler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.