Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Automobile Equipment Technician Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Automobile Equipment Technician Engineer so you can tailor your answers to impress potential employers.

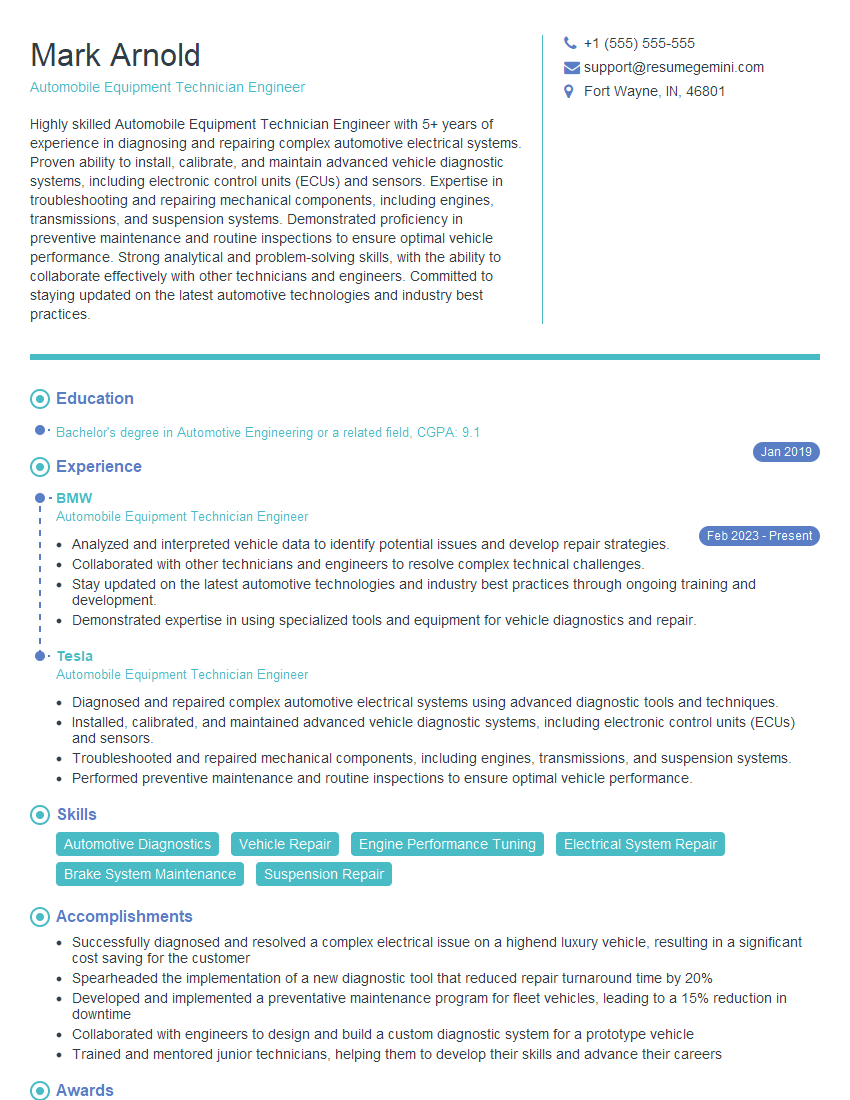

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automobile Equipment Technician Engineer

1. What are the key components of an automotive engine?

The key components of an automotive engine are as follows:

- Engine block: Houses the cylinders, pistons, and crankshaft.

- Cylinder head: Seals the top of the cylinders and contains the valves.

- Pistons: Move up and down inside the cylinders, compressing the air-fuel mixture and providing power.

- Crankshaft: Converts the reciprocating motion of the pistons into rotary motion.

- Camshaft: Controls the opening and closing of the valves.

- Valve train: Consists of the camshaft, valves, and associated components.

- Oil pump: Circulates oil throughout the engine for lubrication.

- Cooling system: Prevents the engine from overheating by circulating coolant.

- Fuel injection system: Delivers fuel to the cylinders.

- Ignition system: Creates the spark that ignites the air-fuel mixture.

2. Explain the working principle of a fuel injector.

- Electromagnetic fuel injector: Utilizes an electromagnetic solenoid to control the opening and closing of a valve, allowing fuel to flow through the injector.

- Piezoelectric fuel injector: Employs piezoelectric crystals to precisely control the flow of fuel, offering faster response times and higher injection pressures.

3. Describe the different types of engine management systems and their advantages and disadvantages.

- Open-loop system: Does not use feedback sensors to adjust fuel delivery, relying solely on predetermined parameters.

- Closed-loop system: Utilizes feedback sensors (e.g., oxygen sensor, mass airflow sensor) to monitor engine performance and adjust fuel delivery accordingly.

- Speed-density system: Calculates air mass based on engine speed and intake manifold pressure.

- Mass airflow system: Measures the actual mass of air entering the engine using a mass airflow sensor.

4. What are the key elements of a vehicle’s suspension system?

- Springs: Absorb shock and vibrations.

- Shock absorbers: Dampen the motion of the springs, preventing excessive oscillations.

- Control arms: Connect the suspension to the vehicle’s frame or body.

- Tie rods: Connect the steering system to the wheels.

- Anti-roll bars: Reduce body roll during cornering.

- Wheels and tires: Provide contact with the road surface and absorb impacts.

5. Explain the operation of a hydraulic brake system.

- Master cylinder: Contains brake fluid and a piston that is actuated when the brake pedal is pressed.

- Brake lines: Carry brake fluid from the master cylinder to the brake calipers.

- Brake calipers: House pistons that squeeze brake pads against brake rotors to slow or stop the vehicle.

- Brake rotors: Attached to the wheels and provide friction for the brake pads.

6. Describe the different types of electronic control modules (ECMs) used in automobiles.

- Engine control module (ECM): Controls the engine’s performance, including fuel injection, ignition timing, and emission control.

- Transmission control module (TCM): Manages the automatic transmission, ensuring smooth shifting and optimal fuel efficiency.

- Body control module (BCM): Integrates various vehicle systems, such as lighting, windows, door locks, and climate control.

- Anti-lock braking system (ABS) module: Prevents wheels from locking during braking, ensuring vehicle stability and control.

7. Explain the importance of vehicle diagnostics and the tools used for this purpose.

- Fault codes: Stored in the vehicle’s computer system to indicate malfunctions.

- Scan tools: Connect to the vehicle’s onboard diagnostic (OBD) port to retrieve and interpret fault codes.

- Multimeters: Measure electrical values (e.g., voltage, resistance, current) to diagnose electrical faults.

- Pressure gauges: Measure pressure in various systems (e.g., fuel, oil, hydraulics).

- Diagnostic software: Provides detailed information about vehicle performance and allows for advanced diagnostics.

8. Describe the process of performing a complete vehicle inspection.

- Visual inspection: Check for leaks, damage, and wear on tires, brakes, belts, and hoses.

- Fluid level checks: Ensure proper levels of engine oil, coolant, brake fluid, transmission fluid, and power steering fluid.

- Electrical system inspection: Test battery, alternator, and starter; check for any loose or damaged wiring.

- Brake inspection: Check brake pads, rotors, and calipers for wear or damage.

- Tire inspection: Check tire pressure, tread depth, and alignment.

- Suspension inspection: Check shock absorbers, springs, and bushings for wear or damage.

- Exhaust system inspection: Check exhaust manifold, catalytic converter, and muffler for leaks or damage.

9. What are the common tools and equipment used in automotive repair and maintenance?

- Hand tools: Wrenches, sockets, screwdrivers, pliers, etc.

- Diagnostic equipment: Scan tools, pressure gauges, multimeters.

- Lifting equipment: Jacks, hoists, lifts.

- Power tools: Drills, impact wrenches, grinders.

- Specialized tools: Valve spring compressors, brake caliper spreaders, etc.

10. Describe the importance of safety precautions in automotive repair.

- Wear appropriate safety gear (e.g., gloves, eye protection, earplugs).

- Use tools properly and never point them at anyone.

- Secure vehicles on lifts or ramps to prevent movement.

- Handle hazardous materials (e.g., fuel, coolant) with care.

- Be aware of potential electrical hazards and follow proper lockout/tagout procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automobile Equipment Technician Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automobile Equipment Technician Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Automobile Equipment Technician Engineers are responsible for maintaining and repairing automotive equipment used in dealerships, repair shops, and other automotive settings. Some key responsibilities of an Automobile Equipment Technician Engineer include:- Troubleshooting and repairing automotive equipment, including lifts, tire changers, diagnostic tools, and other equipment.

- Performing preventative maintenance on automotive equipment, such as cleaning, lubrication, and calibration.

- Inspecting automotive equipment for safety hazards and ensuring compliance with safety regulations.

- Providing technical support to technicians and customers on the use and maintenance of automotive equipment.

- Developing and implementing training programs for technicians on the use and maintenance of automotive equipment.

- Managing inventory of automotive equipment and supplies.

- Staying up-to-date on the latest automotive equipment technology and trends.

Interview Tips

Ace your Automobile Equipment Technician Engineer interview by preparing thoroughly. Research the company and the position to demonstrate your interest and knowledge. Highlight your technical expertise and experience in maintaining and repairing automotive equipment. Emphasize your customer service skills and ability to work independently and as part of a team.- 1. Research the company and the position: Visit the company’s website, read industry publications, and talk to people in your network to learn more about the company and the specific position you’re applying for. This will help you understand the company’s culture, values, and goals, and tailor your answers to the interviewer’s questions accordingly.

- 2. Highlight your technical expertise and experience: Be prepared to discuss your experience in maintaining and repairing automotive equipment. Be specific about the types of equipment you’ve worked on, the problems you’ve solved, and the results you’ve achieved. If you have any certifications or training in automotive equipment repair, be sure to mention those as well.

- 3. Emphasize your customer service skills: Automotive Equipment Technician Engineers often work directly with customers, so it’s important to have strong customer service skills. Be polite, friendly, and helpful, and be able to clearly explain technical concepts to non-technical customers.

- 4. Show your ability to work independently and as part of a team: Most Automobile Equipment Technician Engineers work independently, but they may also be required to work as part of a team. Be able to describe your experience working independently and as part of a team, and highlight your ability to communicate effectively and collaborate with others.

- 5. Prepare questions for the interviewer: Asking thoughtful questions at the end of the interview shows that you’re interested in the position and the company. Prepare a few questions about the company, the position, and the interviewer’s own experience. This will also give you an opportunity to learn more about the company and the position, and make a good impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Automobile Equipment Technician Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!