Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Line Erector Apprentice interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Line Erector Apprentice so you can tailor your answers to impress potential employers.

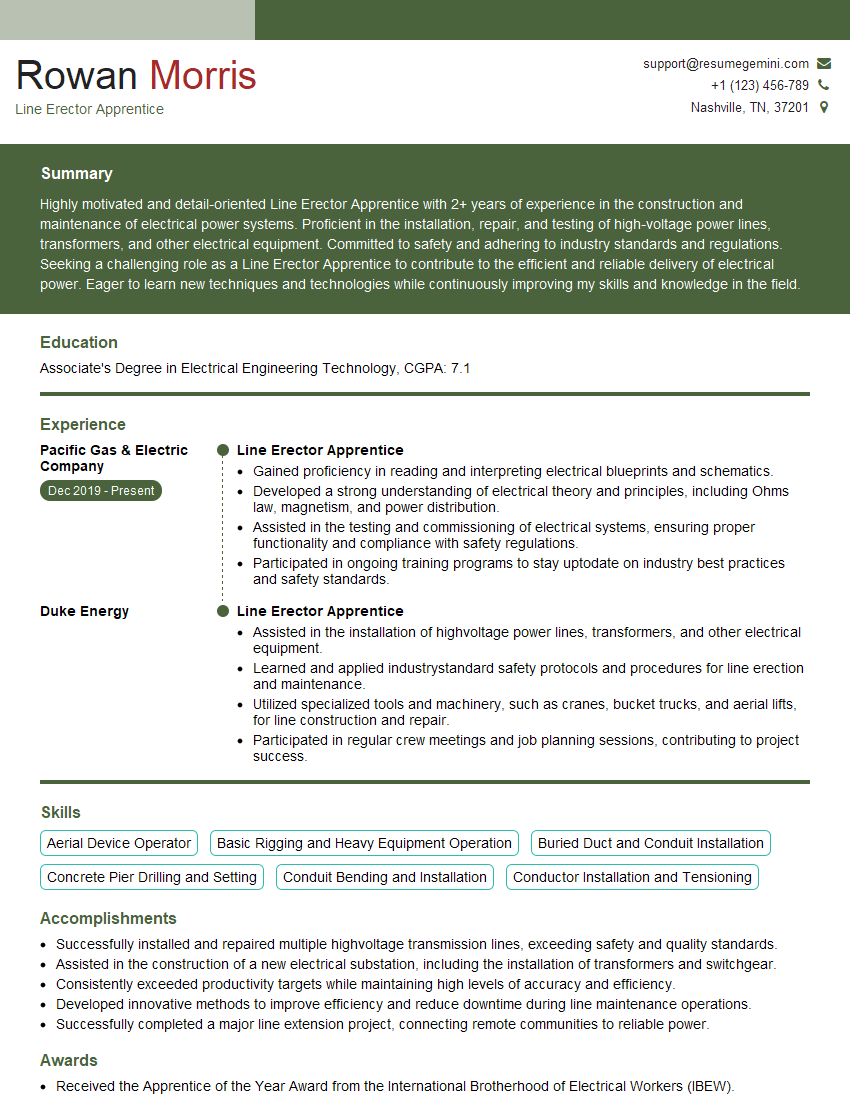

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Line Erector Apprentice

1. What are the types of conductors used in overhead power lines?

There are various types of conductors used in overhead power lines, which include:

- All Aluminium Conductor (AAC)

- All Aluminium Alloy Conductor (AAAC)

- Aluminium Conductor Steel Reinforced (ACSR)

- Copper Conductor

- Composite Core Conductors (e.g., ACCC)

2. Explain the function of spacers in overhead lines.

Maintaining Clearance

- Spacers maintain the desired clearance between conductors, preventing short circuits due to wind-induced conductor swaying.

Reducing Aeolian Vibration

- Spacers dampen aeolian vibrations (caused by wind) that can fatigue conductors and lead to failure.

Controlling Bundle Conductors

- In bundled conductor systems, spacers ensure proper spacing and prevent conductor entanglement.

3. Describe the process of sag adjustment in overhead lines.

Sag adjustment involves modifying the tension of conductors to ensure they meet specific clearance requirements:

- Planning: Calculate the required sag based on factors like conductor type, temperature, and span length.

- Tensioning: Use specialized equipment (e.g., tensioners) to adjust the tension and achieve the desired sag.

- Monitoring: Regularly monitor sag to ensure it remains within acceptable limits, especially during changing temperature conditions.

4. What is corona discharge, and how does it affect overhead lines?

Corona discharge is the ionization of air around high-voltage conductors, resulting in a faint glow and audible crackling sound:

- Impact on Transmission Loss: Corona discharge causes power loss due to the leakage of electrical energy from the conductor.

- Ozone Production: It releases ozone, a corrosive gas that can degrade conductor surfaces.

- Radio Interference: Corona discharge creates electromagnetic interference that can disrupt radio communications.

5. Explain the different methods of grounding overhead lines.

Grounding overhead lines is crucial for safety and fault protection:

- Ground Rods: Driven into the earth to provide a low-resistance path for fault currents.

- Counterpoise Wires: Buried parallel to the line to distribute fault currents over a wider area, reducing ground potential rise.

- Ground Wire: An overhead conductor installed above the phase conductors, which is grounded to divert lightning strikes.

6. What are the safety precautions that must be taken when working on overhead lines?

Stringent safety measures are essential when handling overhead lines:

- Proper PPE: Wear insulated gloves, protective clothing, and a hard hat.

- De-Energization: Ensure the line is de-energized and grounded before any work is performed.

- Clearance Maintenance: Maintain safe working distances from energized conductors and equipment.

- Weather Considerations: Avoid working during inclement weather, such as lightning or high winds.

7. Discuss the factors that affect the choice of insulators for overhead lines.

Selecting insulators for overhead lines involves considering several factors:

- Voltage Level: Insulators must withstand the operating voltage without flashover.

- Environmental Conditions: Insulators should be resistant to moisture, pollution, and extreme temperatures.

- Mechanical Strength: Insulators must withstand wind loads, ice accumulation, and seismic forces.

- Cost-Effectiveness: The cost of insulators must be balanced against their performance and longevity.

8. What is the purpose of a lightning arrester in an overhead line?

Lightning arresters protect overhead lines from lightning strikes by providing a low-resistance path to ground:

- Diverting Lightning Currents: Lightning arresters divert lightning currents into the ground, protecting the line from damage and preventing flashovers.

- Limiting Surges: They limit the voltage surges caused by lightning strikes, safeguarding equipment connected to the line.

9. Describe the process of stringing conductors on overhead lines.

Stringing conductors involves carefully installing the electrical wires on overhead lines:

- Planning: Determine the conductor sagging, tension, and clearance requirements.

- Stringing Equipment: Use specialized equipment (e.g., tensioners, pulleys) to pull the conductors into place.

- Line Support: Secure the conductors to insulators, towers, or poles using appropriate hardware.

- Sag Adjustment: Adjust the conductor tension to achieve the desired sag, ensuring proper clearance and electrical performance.

10. What are the different types of overhead line towers, and which factors influence their design?

Overhead line towers come in various types, each with specific design considerations:

- Lattice Towers: Constructed from steel lattice structures, providing high strength and flexibility.

- Monopole Towers: Single-pole structures, typically used for lower voltage lines in urban areas.

- Guyed Towers: Supported by guy wires to withstand lateral forces, common in areas with limited space.

- Self-Supporting Towers: Designed to withstand forces without external support, used in areas with difficult terrain.

- Height and Span: Tower height and span between towers depend on voltage level, conductor type, and terrain.

- Wind and Ice Loads: Towers must withstand wind and ice loading to ensure stability and prevent collapse.

- Electrical Loading: The tower’s design considers the electrical loads imposed by conductors and insulators.

- Environmental Impact: The tower’s design minimizes environmental impact and visual aesthetics.

Design factors include:

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Line Erector Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Line Erector Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Line Erector Apprentices play a crucial role in the construction and maintenance of electrical power lines and distribution systems. Their responsibilities encompass a wide range of tasks essential for ensuring the safe and efficient delivery of electricity to homes and businesses.

1. Line Construction

Apprentices assist journey-level line erectors in installing, repairing, and maintaining power lines. This involves working with a variety of materials and equipment, including poles, crossarms, insulators, and conductors.

- Lay out and set poles, crossarms, and other support structures

- String and sag electrical conductors

- Install transformers and other electrical equipment

2. Line Maintenance

Apprentices participate in scheduled and emergency maintenance operations to keep power lines in good working order. They inspect lines for potential hazards and perform necessary repairs or replacements.

- Inspect lines and equipment for defects

- Repair damaged poles, crossarms, and insulators

- Replace worn or damaged conductors

3. Troubleshooting and Restoration

In the event of a power outage, apprentices assist in troubleshooting the cause and restoring service. They may be required to locate and repair downed lines or damaged equipment.

- Troubleshoot and identify line faults

- Repair downed lines and damaged equipment

- Restore power to affected areas

4. Safety and Compliance

Apprentices are responsible for adhering to all safety regulations and procedures related to working with electricity. They must maintain a safe work environment and follow all applicable industry standards.

- Follow all safety protocols and procedures

- Maintain a clean and organized work area

- Wear appropriate safety gear at all times

Interview Preparation Tips

Preparing thoroughly for your interview as a Line Erector Apprentice will significantly enhance your chances of success. Below are some valuable tips to help you stand out from other candidates.

1. Research the Company and Industry

Familiarize yourself with the company you are applying to, including its history, size, and industry reputation. Research the electrical power industry and current trends in line construction and maintenance.

2. Review Job Description Carefully

Thoroughly go over the job description and identify the key responsibilities and qualifications. Highlight your skills and experience that match the requirements of the position.

3. Prepare to Discuss Safety

Safety is paramount in the electrical power industry. Demonstrate your understanding of safety protocols and procedures. Emphasize your commitment to working safely and following all applicable industry standards.

4. Highlight Your Physical Abilities

Line Erector Apprentices must be physically fit and capable of performing demanding tasks. Highlight your physical abilities, such as your strength, stamina, and agility.

5. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers. Examples include:

- Tell me about your experience working with electricity.

- Describe a time when you had to troubleshoot a line fault.

- What is your understanding of the National Electrical Code?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Line Erector Apprentice interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.