Feeling lost in a sea of interview questions? Landed that dream interview for Cryogenics Repairer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cryogenics Repairer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

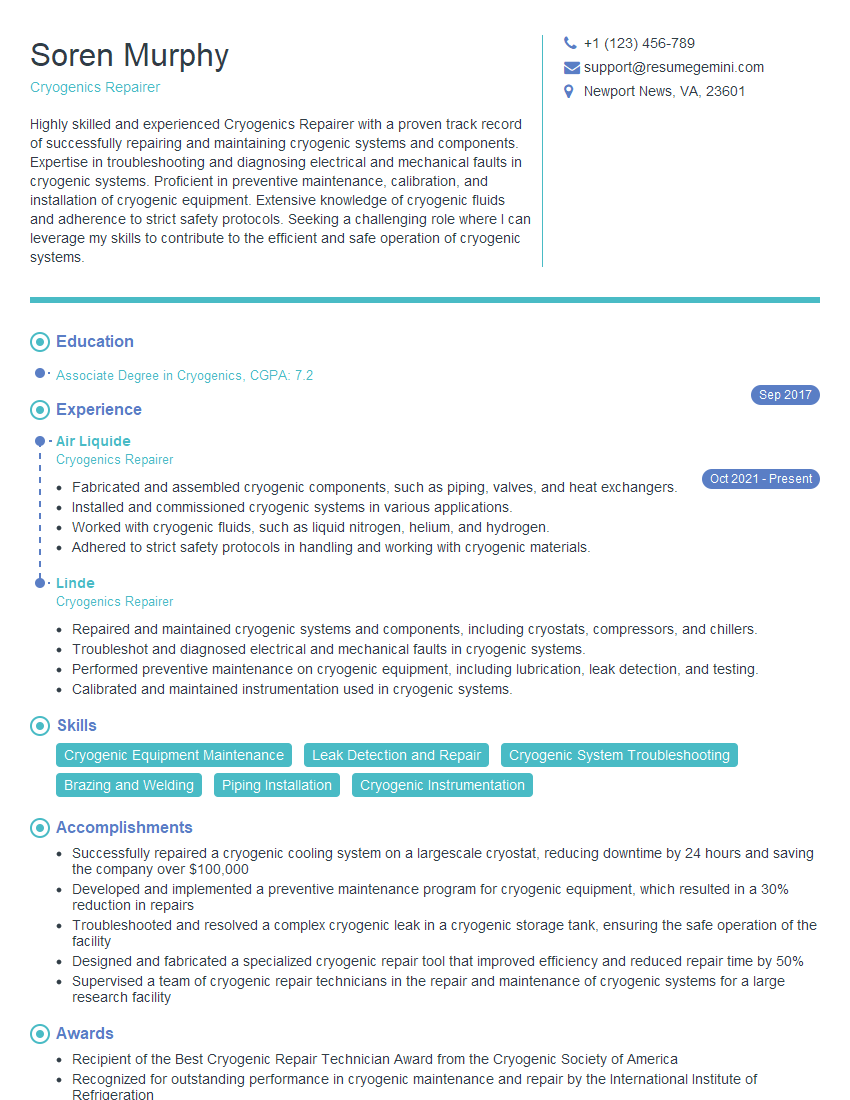

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cryogenics Repairer

1. What are the different types of cryogenic systems and their applications?

Cryogenic systems can be broadly classified into two main types:

- Closed-cycle systems:

- Refrigerators and liquefiers that use mechanical means such as compressors and expanders to circulate and cool the working fluid.

- Applications include the production of ultra-low temperatures for scientific research, industrial processes, and medical treatments.

- Open-cycle systems:

- Vaporize liquid cryogens such as liquid nitrogen or helium to produce cooling.

- Applications include cryosurgery, food freezing, and cooling of superconducting materials.

2. Describe the safety precautions that must be taken when working with cryogenic liquids and gases.

Personal Protective Equipment (PPE):

- Cryogenic gloves and clothing

- Face shield or safety goggles

- Respiratory protection (if handling large quantities or in confined spaces)

Handling and Storage:

- Use proper cryogenic containers

- Store cryogens in well-ventilated areas

- Handle containers carefully to avoid spills and leaks

Emergency Procedures:

- Know the location of safety showers and eyewash stations

- Be aware of evacuation procedures

- Have an emergency plan in place

3. How do you troubleshoot and repair a leaking cryogenic valve?

- Identify the source of the leak

- Isolating the leaking valve

- Purging the valve

- Replacing seals or gaskets

- Reassembling the valve

- Testing the valve for leaks

4. Explain the importance of maintaining proper vacuum in a cryogenic system.

- Prevents heat transfer by conduction and convection

- Reduces the evaporation rate of cryogenic liquids

- Improves the efficiency of the system

- Prevents the formation of ice crystals in the system

5. Describe the different methods used to measure and control cryogenic temperatures.

Measurement Methods:

- Thermocouples

- Resistance Temperature Detectors (RTDs)

- Infrared sensors

Control Methods:

- Temperature controllers

- Proportional-Integral-Derivative (PID) controllers

- Cryogenic thermostats

6. What are the common materials used in the construction of cryogenic systems and what are their properties?

- Metals:

- Stainless steel

- Aluminum

- Copper

- Insulators:

- Perlite

- Aerogel

- Multi-layer insulation

7. How do you ensure the quality of welds in cryogenic systems?

- Use qualified welders

- Follow proper welding procedures

- Inspect welds using NDT methods

- Helium leak testing

8. Describe the process of cryogenic cleaning.

- Immerse the part in liquid nitrogen or other cryogenic fluid

- Agitate the part to remove contaminants

- Remove the part and let it warm up

- Inspect the part for cleanliness

9. How do you handle and transport cryogenic liquids safely?

- Use proper cryogenic containers

- Secure containers during transport

- Avoid sudden movements or impacts

- Monitor temperature and pressure

- Have emergency equipment available

10. What are the challenges faced in the design and maintenance of cryogenic systems?

- Low temperatures and high pressures

- Thermal expansion and contraction

- Material compatibility

- Safety and environmental concerns

- Cost and complexity

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cryogenics Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cryogenics Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cryogenics Repairer is responsible for maintaining, troubleshooting, and repairing cryogenic equipment and systems. This can include a wide range of tasks, such as:

1. Troubleshooting and repairing cryogenic systems

- Diagnosing and repairing faults in cryogenic systems, such as refrigerators, freezers, and liquefiers.

- Replacing or repairing faulty components, such as compressors, pumps, and valves.

2. Maintaining cryogenic equipment

- Performing regular maintenance on cryogenic equipment, such as cleaning, lubrication, and calibration.

- Replacing worn or damaged parts.

3. Installing cryogenic systems

- Installing new cryogenic systems, such as refrigerators, freezers, and liquefiers.

- Connecting and testing cryogenic systems.

4. Operating cryogenic systems

- Operating cryogenic systems, such as refrigerators, freezers, and liquefiers.

- Monitoring cryogenic systems for proper operation.

Interview Tips

To ace an interview for a Cryogenics Repairer position, it is important to be prepared to answer questions about your experience and skills. Here are a few tips:

1. Research the company and the position

- Visit the company’s website to learn about their business, products, and services.

- Read the job description carefully to understand the specific requirements of the position.

2. Practice your answers to common interview questions

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice your answers out loud to ensure that you are clear and concise.

3. Dress professionally

- First impressions matter, so dress professionally for your interview.

- This means wearing a suit or business casual attire.

4. Be confident and enthusiastic

- Confidence is key in any interview.

- Be enthusiastic about the position and the company.

5. Ask questions

- Asking questions at the end of the interview shows that you are interested in the position and the company.

- Prepare a few questions to ask the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cryogenics Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!