Feeling lost in a sea of interview questions? Landed that dream interview for Dental Equipment Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dental Equipment Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

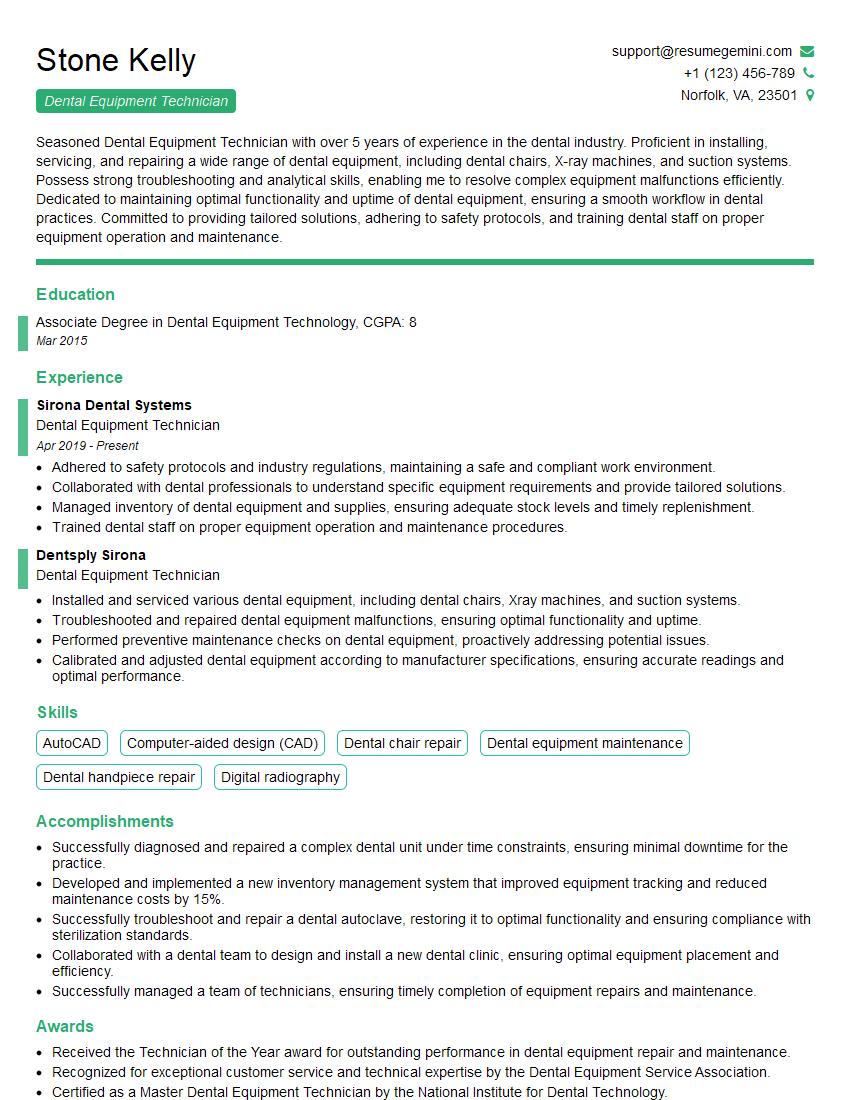

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dental Equipment Technician

1. How do you troubleshoot a dental X-ray machine that is not producing images?

- Check if the power cord is securely plugged in, and the machine is turned on.

- Ensure that the X-ray tube is connected properly and the filament is intact.

- Examine the X-ray timer for any signs of damage or malfunction.

- Inspect the X-ray generator for any indicators of electrical problems.

- Verify that the film processor is functioning correctly and loaded with fresh chemicals.

2. Describe the steps involved in repairing a dental autoclave.

Visual Inspection

- Inspect the autoclave for any physical damage or leaks.

- Check the power cord and connections for any irregularities.

Electrical Troubleshooting

- Test the power supply to the autoclave using a voltmeter.

- Examine the electrical components, such as the heating element, pressure sensor, and timer, for signs of malfunction.

Mechanical Troubleshooting

- Inspect the door gasket for damage or wear, as a compromised gasket can affect the autoclave’s ability to seal properly.

- Check the water valve and drain system for any blockages or leaks.

3. How would you calibrate a dental curing light?

Calibrating a dental curing light requires the use of a radiometer or power meter designed specifically for this purpose.

- Ensure that the radiometer is calibrated according to the manufacturer’s instructions.

- Set up the radiometer with the appropriate sensor for the type of curing light being calibrated.

- Place the sensor at the specified distance from the light source and activate the curing light.

- Record the light intensity reading displayed on the radiometer.

- Repeat the process as necessary and adjust the curing light’s settings until the desired intensity is achieved.

4. How do you maintain a dental handpiece?

- Regularly clean and lubricate the handpiece according to the manufacturer’s recommendations.

- Ensure proper sterilization of the handpiece between uses.

- Inspect the handpiece for any signs of damage or wear, such as loose or damaged burrs, and replace them as needed.

- Check the handpiece’s air and water supply lines for any blockages or leaks.

5. How do you remove plaque and tartar from dental instruments?

There are several effective methods to remove plaque and tartar from dental instruments.

- Ultrasonic Cleaner: Submerge the instruments in an ultrasonic cleaner filled with a specialized cleaning solution. The ultrasonic waves will dislodge the plaque and tartar.

- Manual Cleaning: Use a soft-bristled brush and tartar-removing paste to gently scrub the instruments. Rinse thoroughly with water.

- Chemical Soaking: Soak the instruments in a solution of enzymatic cleaner or hydrogen peroxide for the recommended time, then rinse thoroughly.

6. How do you test the suction of a dental vacuum system?

- Attach a suction gauge to the suction line.

- Turn on the vacuum system and observe the gauge reading.

- Compare the reading to the manufacturer’s specifications for the suction system.

- If the suction is below the specified level, troubleshoot potential issues such as blockages in the tubing, a faulty vacuum pump, or leaks in the system.

7. How do you maintain a dental chair?

- Regularly clean and disinfect all surfaces of the chair, including the upholstery, armrests, and headrest.

- Inspect the chair’s mechanical components, such as the motor, hydraulics, and foot controls, for proper function.

- Lubricate moving parts as per the manufacturer’s instructions.

- Tighten any loose screws or bolts to ensure stability.

8. How do you troubleshoot a dental amalgamator that is not mixing materials properly?

- Check if the amalgamator is properly plugged in and receiving power.

- Inspect the mixing chamber and blades for any damage or wear.

- Ensure that the correct ratio of mercury and alloy is being used.

- Verify that the amalgamator’s timer is set to the appropriate mixing time.

- Clean the amalgamator thoroughly to remove any debris that may be interfering with the mixing process.

9. What safety precautions should be taken when working with dental equipment?

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a lab coat.

- Be aware of potential electrical hazards and follow proper lockout/tagout procedures.

- Handle sharp instruments with care to avoid cuts or punctures.

- Dispose of sharps and other hazardous materials in designated containers.

- Maintain a clean and organized work area to prevent accidents.

10. How do you stay up-to-date with advancements in dental equipment technology?

- Attend industry conferences and trade shows.

- Read dental journals and publications.

- Take continuing education courses and workshops.

- Network with other dental professionals and equipment manufacturers.

- Research new technologies and products online.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dental Equipment Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dental Equipment Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dental Equipment Technician is responsible for maintaining, repairing, and Calibrating dental equipment used in dental practices. This includes diagnosing problems with equipment, carrying out repairs, and providing maintenance to ensure the smooth functioning of the equipment.

1. Equipment Maintenance and Repair

The technician is responsible for diagnosing and troubleshooting problems with dental equipment, including chairs, x-ray machines, and suction units. Once the issue has been identified, the technician will determine the best course of action to repair the equipment, either by replacing parts or performing repairs on-site.

- Diagnose and troubleshoot problems with dental equipment

- Repair and replace parts on dental equipment

2. Equipment Calibration and Inspection

Dental Equipment Technicians are responsible for ensuring that dental equipment is properly calibrated to meet regulatory standards. This includes performing routine inspections and testing to ensure that the equipment is safe and operating correctly. They also maintain records of all maintenance and calibration work performed on the equipment.

- Calibrate and inspect dental equipment to ensure compliance with regulations

- Maintain records of all maintenance and calibration work performed

3. Customer Service

Dental Equipment Technicians need to have excellent customer service skills to interact with dental professionals and provide support. They must be able to clearly explain technical information and answer questions effectively. They may also be required to provide training on the use of new equipment.

- Provide excellent customer service to dental professionals

- Effectively answer questions and explain technical information

- Provide training on the use of new equipment

4. Safety and Compliance

Dental Equipment Technicians must adhere to all safety regulations and guidelines to ensure the safe operation of dental equipment. They must be knowledgeable about the latest industry standards and follow all manufacturer recommendations for the maintenance and repair of equipment.

- Adhere to all safety regulations and guidelines

- Be knowledgeable about the latest industry standards

- Follow all manufacturer recommendations

Interview Tips

Interview preparation is essential to showcase your skills and qualifications and ace your interview for a Dental Equipment Technician position. Here are some tips to help you prepare effectively:

1. Research the Company and Position

Before the interview, take the time to research the company you’re applying to, as well as the specific Dental Equipment Technician position. This will give you a better understanding of the company’s culture, values, and the specific responsibilities of the role.

- Visit the company’s website and social media pages

- Read industry publications and articles to stay up-to-date on the latest trends

2. Practice Your Answers

Once you have a good understanding of the company and position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the actual interview.

- Use the STAR method to answer behavioral interview questions

- Prepare specific examples of your skills and experience that align with the job requirements

3. Be Yourself and Be Enthusiastic

During the interview, it’s important to be yourself and let your personality shine through. Be enthusiastic about the opportunity and express your interest in the company and position. Also, be sure to maintain a positive and professional demeanor during the interview.

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Ask thoughtful questions to show your interest and engagement

4. Follow Up After the Interview

After the interview, take the time to follow up with the interviewer. Thank them for their time and consideration, and reiterate your interest in the position. You can also send a brief email or letter to reiterate your key qualifications and how you believe you can add value to the team.

- Send a thank-you email within 24 hours

- Reiterate your interest in the position

- Highlight your key qualifications and how you can benefit the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dental Equipment Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!