Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Durable Medical Equipment Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

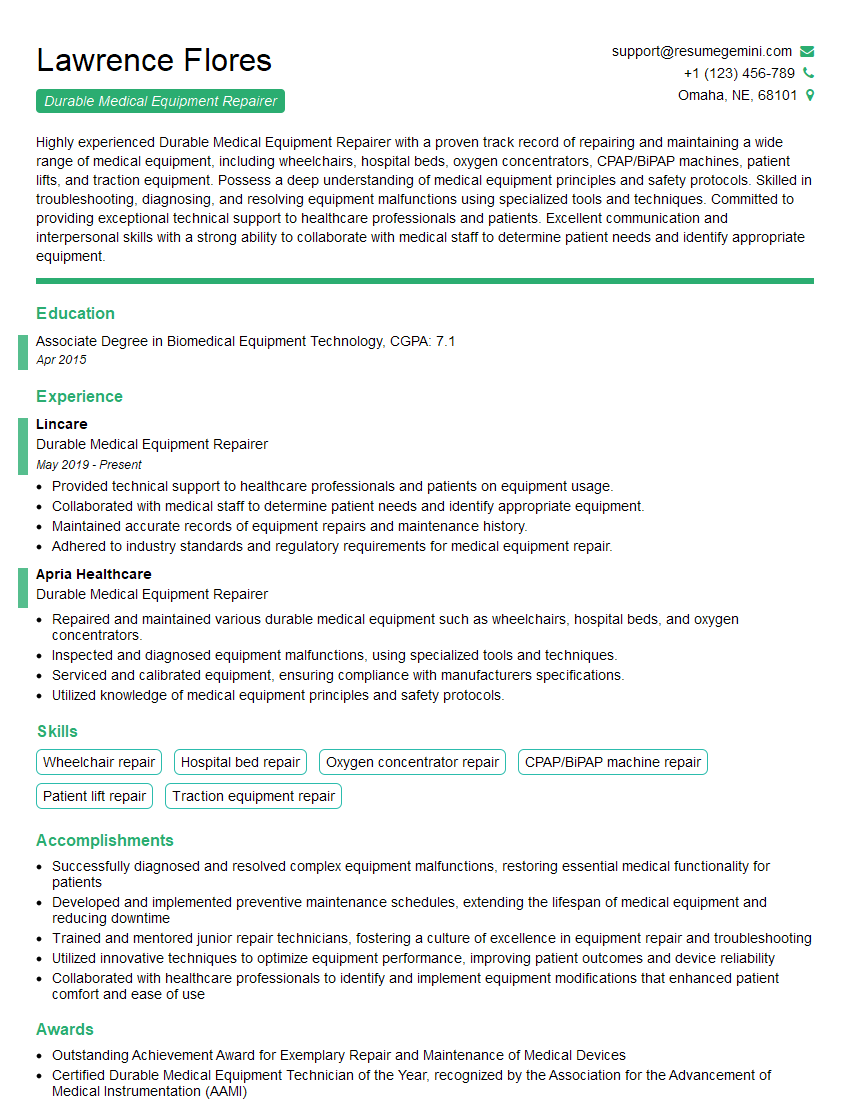

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Durable Medical Equipment Repairer

1. How would you troubleshoot a power wheelchair that is not moving?

To troubleshoot a power wheelchair that is not moving, I would follow these steps:

- Check the battery level and connections to ensure the wheelchair has enough power.

- Inspect the joystick and wiring to make sure they are functioning correctly and not damaged or loose.

- Examine the motors and wheels for any blockages or obstructions preventing movement.

- Check the circuit breakers and fuses to see if they have tripped or blown, which can interrupt power to the wheelchair.

- Test the charging system to ensure the battery can hold a charge and is not faulty.

2. What safety precautions should be taken when working on a hospital bed?

Electrical Safety

- Unplug the bed from the power source before performing any maintenance or repairs.

- Inspect the electrical cords and wires for damage, and replace any faulty components.

Mechanical Safety

- Ensure the bed is in a stable position and securely locked before working on it.

- Use proper lifting techniques and seek assistance when handling heavy components.

Patient Safety

- Move the patient to a safe location before beginning work on the bed.

- Protect the patient from sharp edges or moving parts during repairs.

3. How would you repair a leak in an oxygen concentrator?

To repair a leak in an oxygen concentrator, I would follow these steps:

- Identify the source of the leak using a soapy water solution or an electronic leak detector.

- Tighten any loose connections, replace faulty seals or gaskets, and repair cracks or holes in hoses or tubing.

- Ensure proper alignment and seating of components, as misalignment can cause leaks.

- Replace worn or damaged components, such as filters or membranes, that may contribute to leaks.

- Test the concentrator for proper operation and seal integrity after repairs are made.

4. What is the difference between a CPAP machine and a BiPAP machine?

A CPAP (Continuous Positive Airway Pressure) machine provides a constant level of air pressure to the patient’s airway to keep it open during sleep. It is commonly used to treat sleep apnea, a condition where breathing repeatedly stops and starts during the night.

A BiPAP (Bilevel Positive Airway Pressure) machine provides two levels of air pressure: a higher pressure during inhalation and a lower pressure during exhalation. It is often used for patients with more severe sleep apnea or other respiratory conditions that require additional support.

5. How would you calibrate a pulse oximeter?

To calibrate a pulse oximeter, I would follow these steps:

- Turn on the pulse oximeter and allow it to warm up for a few minutes.

- Place a finger probe on the patient’s finger, ensuring it is properly seated and aligned.

- Using a calibration device or software, set the pulse oximeter to the desired calibration values (e.g., 100% oxygen saturation).

- Check the accuracy of the calibration by comparing the pulse oximeter readings to a known reference source, such as a blood gas analyzer.

- Document the calibration date and any adjustments made.

6. What are the common challenges faced while repairing medical equipment?

- Complex technology: Medical equipment often incorporates advanced electronics and software, requiring specialized knowledge and skills to diagnose and repair.

- Time constraints: Equipment repairs need to be completed promptly to minimize downtime and ensure patient care is not compromised.

- Safety concerns: Improper repairs can compromise patient safety, so it is crucial to adhere to strict safety protocols and regulations.

- Access to parts: Some medical equipment may require specialized or rare parts, which can be difficult to procure quickly.

- Limited documentation: Technical documentation for medical equipment may not always be readily available or comprehensive.

7. What is the importance of preventive maintenance for medical equipment?

- Increased equipment lifespan: Regular maintenance helps identify and address potential issues early on, preventing major breakdowns and extending the equipment’s life.

- Improved safety: Preventive maintenance reduces the risk of equipment failures, ensuring patient safety and minimizing the likelihood of accidents.

- Reduced downtime: By detecting and resolving minor issues before they become major problems, preventive maintenance helps minimize equipment downtime and ensures smooth operation.

- Cost savings: Proactive maintenance can prevent costly repairs or replacements in the long run.

- Regulatory compliance: Many healthcare facilities are required to follow specific regulations and standards for medical equipment maintenance.

8. How do you stay up-to-date with advancements in medical equipment technology?

- Attend industry conferences and seminars: These events provide opportunities to learn about new technologies and best practices.

- Read industry publications and journals: Keep up with the latest advancements through specialized magazines and online resources.

- Participate in online forums and discussions: Connect with other professionals and exchange knowledge on emerging technologies.

- Collaborate with manufacturers and suppliers: They can provide information on new product releases and technological innovations.

- Attend training courses and workshops: These programs can provide hands-on experience with new technologies.

9. Can you describe a complex repair you have successfully completed?

In a complex repair, I was tasked with fixing an MRI machine that had a malfunctioning gradient amplifier. The issue required in-depth knowledge of electronics, software, and the specific MRI system. I systematically diagnosed the problem, identified the faulty component, and replaced it with a new one. After reassembling the machine and testing its functionality, the MRI was successfully restored to full operation, ensuring uninterrupted patient care.

10. How do you prioritize repairs when faced with multiple urgent requests?

- Assess the criticality of the equipment: Determine which devices are essential for patient care and prioritize their repairs.

- Consider the impact on patient safety: Address repairs that pose a potential risk to patients first.

- Evaluate the consequences of downtime: Estimate the impact of equipment failure on patient care and workflow.

- Communicate with the clinical staff: Consult with healthcare professionals to understand the urgency of repairs and any alternative arrangements that can be made.

- Manage expectations: Keep stakeholders informed about repair progress and provide realistic timeframes for completion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Durable Medical Equipment Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Durable Medical Equipment Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Durable Medical Equipment Repairer is an in-demand role in the healthcare industry responsible for maintaining and repairing medical devices and equipment. The primary focus of this position is to ensure that medical equipment is functioning properly and safely for patients and users.

1. Equipment Maintenance and Troubleshooting

Conduct regular inspections, preventive maintenance, and repairs of durable medical equipment.

- Diagnose equipment malfunctions and determine appropriate solutions.

- Replace defective components, calibrate equipment, and perform adjustments.

2. Safety and Compliance

Prioritize the safety of patients and users by adhering to industry standards and regulations.

- Follow established safety protocols and procedures.

- Test and certify equipment to meet safety requirements.

3. Customer Service

Interact with patients, healthcare professionals, and other stakeholders to provide excellent customer service.

- Respond promptly to service requests and inquiries.

- Provide clear explanations of technical issues and repair processes.

4. Documentation and Reporting

Maintain accurate records of equipment maintenance, repairs, and inspections.

- Document all repairs, including parts used and labor hours.

- Prepare reports on equipment performance and maintenance needs.

Interview Tips

Preparing for an interview as a Durable Medical Equipment Repairer requires careful research and a thorough understanding of the role’s technical aspects and responsibilities. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s mission, values, and services. Understand the healthcare industry and the specific needs of the equipment you will be repairing.

- Visit the company’s website and social media pages.

- Read articles and reports on the latest advancements in medical equipment.

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in repairing and maintaining medical equipment. Quantify your experience with specific examples.

- Describe your experience with different types of medical equipment.

- Provide examples of complex repairs or troubleshooting scenarios you have successfully resolved.

3. Demonstrate Your Commitment to Safety

Stress your understanding of safety regulations and your commitment to maintaining a safe work environment.

- Explain your knowledge of industry standards and codes.

- Describe your experience in following safety protocols and procedures.

4. Prepare for Customer Service Questions

Show your ability to communicate effectively and provide excellent customer service.

- Describe your approach to resolving customer inquiries and complaints.

- Share examples of how you have exceeded customer expectations.

5. Ask Thoughtful Questions

Asking well-informed questions not only demonstrates your interest in the role but also helps you gather valuable information about the company and the position.

- Inquire about the company’s growth plans and future projects.

- Ask about the specific equipment you will be working on and the training provided.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Durable Medical Equipment Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!