Are you gearing up for an interview for a Industrial Maintenance Repairer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Industrial Maintenance Repairer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

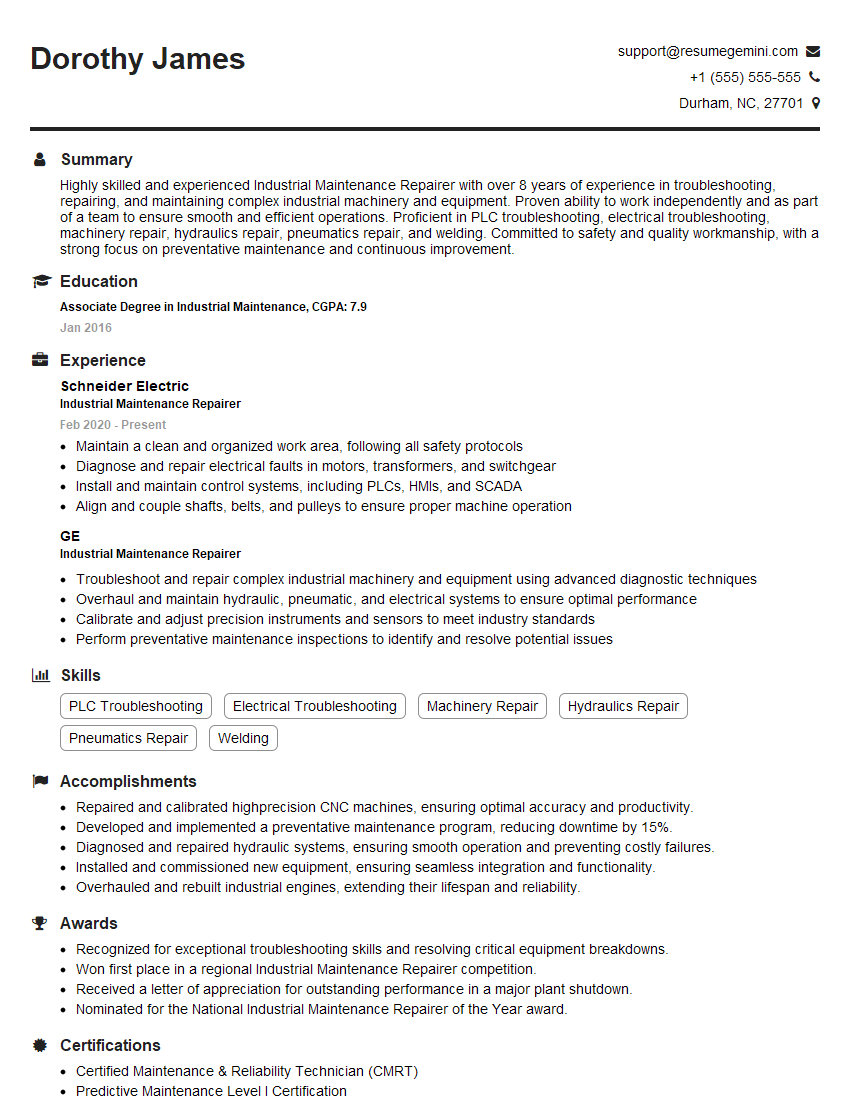

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Maintenance Repairer

1. What are the steps involved in troubleshooting an electrical component?

The steps involved in troubleshooting an electrical component include:

- Identify the problem.

- Gather information.

- Develop a hypothesis.

- Test the hypothesis.

- Implement the solution.

2. How would you approach a situation where a machine is not functioning properly?

Troubleshooting

- Gather information about the machine and its operating history.

- Observe the machine in operation and note any abnormalities.

- Check the machine’s maintenance records.

- Consult with the machine’s manufacturer or other experts.

Repairing

- Once the problem has been identified, repair the machine according to the manufacturer’s instructions.

- Test the machine to ensure that it is functioning properly.

- Document the repair.

3. What is the importance of preventative maintenance?

Preventative maintenance is important because it can help to:

- Reduce the likelihood of breakdowns.

- Extend the life of equipment.

- Improve safety.

- Reduce maintenance costs.

4. What are some of the common tools and equipment used by industrial maintenance repairers?

- Hand tools (e.g., wrenches, screwdrivers, pliers)

- Power tools (e.g., drills, saws, grinders)

- Measuring and testing equipment (e.g., multimeters, oscilloscopes)

- Welding and cutting equipment

- Personal protective equipment (e.g., safety glasses, gloves, earplugs)

5. What are some of the safety hazards that industrial maintenance repairers may encounter?

- Electrical hazards

- Mechanical hazards

- Chemical hazards

- Fire hazards

- Slips, trips, and falls

6. What are some of the skills and qualities that are important for industrial maintenance repairers?

- Strong mechanical skills

- Electrical knowledge

- Problem-solving skills

- Attention to detail

- Physical stamina

- Teamwork skills

7. What are some of the challenges that industrial maintenance repairers face?

- Working with complex machinery

- Troubleshooting problems quickly and efficiently

- Working in hazardous environments

- Keeping up with new technologies

- Meeting production deadlines

8. What are some of the career advancement opportunities for industrial maintenance repairers?

- Maintenance supervisor

- Maintenance manager

- Plant engineer

- Project manager

- Consultant

9. What is your favorite part about working as an industrial maintenance repairer?

My favorite part about working as an industrial maintenance repairer is the variety of work that I get to do. I enjoy the challenge of troubleshooting problems and finding solutions.

10. What is your biggest accomplishment as an industrial maintenance repairer?

My biggest accomplishment as an industrial maintenance repairer was when I was able to troubleshoot and repair a complex machine that had been down for several days. The machine was critical to the production process, and I was able to get it up and running again quickly and efficiently.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Maintenance Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Maintenance Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Industrial Maintenance Repairers are responsible for maintaining, troubleshooting, and repairing industrial machinery within a wide range of production settings. Their main aim is to ensure the smooth operation of equipment, minimizing downtime, and maintaining a safe working environment. Their duties span a comprehensive range of skill sets involving mechanical, electrical, and hydraulic systems.

1. Maintenance and Repair

Industrial Maintenance Repairers play a pivotal role in the upkeep and repair of industrial machinery. They conduct routine preventive maintenance checks adhering strictly to manufacturers’ specifications. These checks involve lubrication, adjustments, and replacement of worn or malfunctioning parts, proactively preventing unscheduled downtime.

- Perform repairs on mechanical, electrical, and hydraulic systems.

- Test and troubleshoot equipment to identify and resolve issues.

- Inspect and maintain equipment to prevent breakdowns.

- Replace and repair faulty components, ensuring the optimal functioning of machinery.

2. Equipment Installation and Setup

Industrial Maintenance Repairers are entrusted with the installation and setup of new machinery within the production facility. They collaborate with vendors to ensure the proper setup and commissioning of these machines. Additionally, they provide training to operators on correct equipment usage and maintenance procedures.

- Install and set up new machinery according to specifications.

- Calibrate and test equipment to ensure accuracy and reliability.

- Train operators on the safe and effective use of equipment.

- Monitor equipment performance and make adjustments as needed.

3. Emergency Response

Industrial Maintenance Repairers are the first responders to any equipment-related emergencies that occur within the production facility. They swiftly diagnose and resolve issues, minimizing downtime and potential safety hazards. They collaborate with production teams to assess the situation, implement temporary fixes if necessary, and coordinate repairs as promptly as possible.

- Respond to emergency breakdowns and troubleshoot issues.

- Diagnose and repair equipment failures quickly and efficiently.

- Collaborate with production teams to minimize downtime.

- Implement temporary repairs to ensure production continuity.

4. Preventative Maintenance

Industrial Maintenance Repairers assume a proactive role in implementing preventative maintenance programs to extend equipment lifespan and minimize breakdowns. They meticulously adhere to maintenance schedules, meticulously inspecting equipment for potential issues and conducting repairs before they escalate into major problems. This approach optimizes productivity, enhances equipment longevity, and lowers overall maintenance costs.

- Develop and implement preventative maintenance programs.

- Inspect equipment regularly to identify potential problems.

- Schedule and perform maintenance tasks as per the maintenance plan.

- Maintain accurate records of all maintenance activities performed.

Interview Tips

Preparing for an Industrial Maintenance Repairer interview demands thoroughness and attention to detail. Here are some essential tips to help you ace the interview and secure the job.

1. Research the Company and the Role

Before the interview, dedicate time to thoroughly research the company and the specific Industrial Maintenance Repairer role you’re applying for. This will demonstrate your enthusiasm for the position and the company, and it will allow you to ask informed questions during the interview.

- Visit the company’s website to learn about their industry, products, and culture.

- Read online reviews and articles about the company to gather insights into its reputation.

- Review the job description thoroughly to understand the key responsibilities and qualifications required.

2. Highlight Your Skills and Experience

During the interview, confidently showcase your skills and experience that align with the job requirements. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Describe your experience in maintaining and repairing industrial machinery, emphasizing your proficiency in mechanical, electrical, and hydraulic systems.

- Highlight your ability to troubleshoot and resolve equipment issues quickly and efficiently.

- Provide examples of how you have implemented preventative maintenance programs to minimize downtime and extend equipment lifespan.

3. Prepare for Technical Questions

Be prepared to answer technical questions related to industrial maintenance repair. These questions may cover topics like electrical schematics, mechanical troubleshooting, and hydraulic systems.

- Review basic electrical concepts, such as Ohm’s Law, electrical circuits, and wiring.

- Familiarize yourself with common mechanical troubleshooting techniques.

- Have a general understanding of hydraulic systems, including pumps, valves, and cylinders.

4. Practice Your Communication Skills

In the interview, strong communication skills are crucial for conveying your ideas clearly and confidently. Practice answering questions succinctly and effectively.

- Prepare a concise and engaging introduction that highlights your key qualifications.

- Rehearse answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Prepare thoughtful questions to ask the interviewer, demonstrating your interest in the company and the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Industrial Maintenance Repairer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.