Are you gearing up for an interview for a Underwater Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Underwater Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

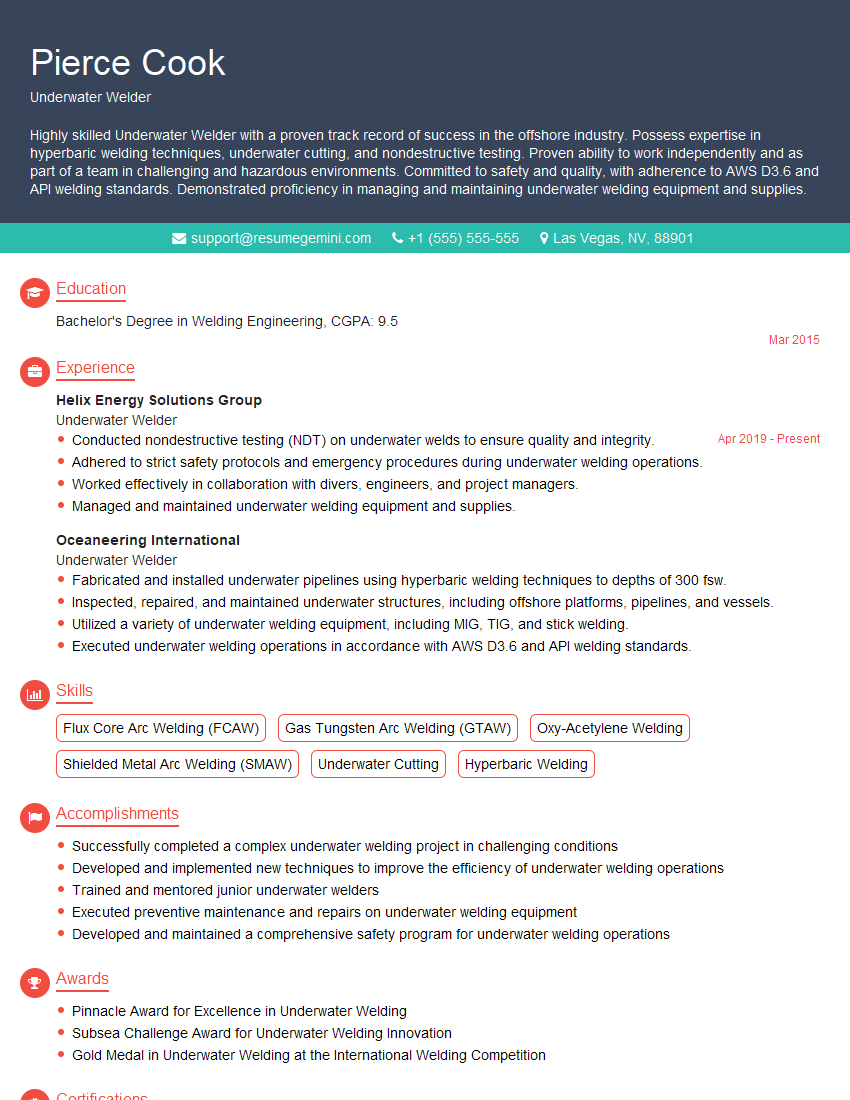

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Underwater Welder

1. What are the different types of underwater welding processes?

There are two main types of underwater welding processes:

- Wet welding: This process is performed in water, and the welder uses a waterproof welding torch to create the weld. Wet welding is typically used for repairs and construction work.

- Dry welding: This process is performed in a dry environment, and the welder uses a welding chamber to create the weld. Dry welding is typically used for more complex welding applications.

2. What are the safety precautions that need to be taken when underwater welding?

Personal safety precautions

- Wear a dry suit or diving suit to protect against cold water and pressure.

- Wear a welding helmet and gloves to protect against sparks and molten metal.

- Use a welding torch that is specifically designed for underwater use.

Environmental safety precautions

- Ensure that the welding area is free of debris and other hazards.

- Use a welding torch that produces minimal smoke and fumes.

- Dispose of welding waste properly.

3. What are the challenges of underwater welding?

- Water visibility: The water can be murky, making it difficult to see the welding area.

- Water currents: The water currents can move the welder and the welding torch, making it difficult to control the weld.

- Pressure: The water pressure can be high, which can make it difficult to breathe and move.

- Temperature: The water temperature can be cold, which can make it difficult to work for long periods of time.

4. What are the different types of underwater welding equipment?

- Welding torch: The welding torch is the most important piece of equipment for underwater welding. It is used to create the weld by melting the metal together.

- Welding helmet: The welding helmet protects the welder’s face and eyes from sparks and molten metal.

- Welding gloves: The welding gloves protect the welder’s hands from heat and sparks.

- Diving suit: The diving suit protects the welder from cold water and pressure.

- Welding chamber: The welding chamber is used to create a dry environment for welding.

5. What are the different types of welds that can be performed underwater?

- Butt weld: This is the most common type of weld and is used to join two pieces of metal together.

- Edge weld: This type of weld is used to join two pieces of metal together that are at an angle to each other.

- Fillet weld: This type of weld is used to join two pieces of metal together that are perpendicular to each other.

- Overhead weld: This type of weld is performed when the welder is working above the weld joint.

6. What are the different materials that can be welded underwater?

- Steel: Steel is the most common material that is welded underwater.

- Stainless steel: Stainless steel is also a popular material for underwater welding.

- Aluminum: Aluminum is a lighter material that is often used for underwater welding.

- Titanium: Titanium is a strong and lightweight material that is often used for underwater welding in marine environments.

7. What are the welding codes and standards that apply to underwater welding?

- American Welding Society (AWS): AWS is a non-profit organization that develops welding codes and standards.

- American Society of Mechanical Engineers (ASME): ASME is a non-profit organization that develops codes and standards for mechanical engineering.

- International Organization for Standardization (ISO): ISO is a worldwide federation of national standards bodies.

8. What are the career opportunities for underwater welders?

- Commercial diver: Commercial divers work in a variety of underwater environments, including construction, repair, and maintenance.

- Offshore oil and gas industry: Underwater welders are needed to work on offshore oil and gas platforms.

- Military: Underwater welders are needed to work on submarines and other military vessels.

- Scientific research: Underwater welders are needed to work on scientific research projects, such as underwater exploration and archaeology.

9. What are the training and certification requirements for underwater welders?

- Commercial diver certification: Most underwater welders must be certified as commercial divers.

- Welding certification: Underwater welders must also be certified in welding.

- Underwater welding certification: Some organizations offer underwater welding certification programs.

10. What are the salary expectations for underwater welders?

- The salary expectations for underwater welders can vary depending on their experience and location.

- According to the U.S. Bureau of Labor Statistics, the median annual salary for commercial divers is $61,820.

- Underwater welders with more experience and specialized skills can earn significantly more.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Underwater Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Underwater Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Underwater Welders perform a wide range of demanding tasks associated with underwater welding in challenging environments such as offshore oil rigs, underwater pipelines, and ship hulls. Here are their key job responsibilities:

1. Welding and Fabrication

Execute underwater welding and fabrication operations to repair, maintain, and install underwater structures and components.

- Weld and cut metal structures using specialized underwater welding equipment.

- Fabricate and assemble underwater components, including pipelines, valves, and fittings.

2. Equipment Operation

Operate and maintain specialized underwater welding equipment, including diving suits, welding machines, and cutting tools.

- Ensure that all equipment is in good working condition and ready for use.

- Troubleshoot and repair equipment malfunctions underwater.

3. Safety and Inspection

Adhere to strict diving and welding safety protocols to ensure the safety of personnel and the integrity of underwater structures.

- Conduct pre-dive safety checks and follow all dive procedures.

- Inspect underwater structures and components for defects and corrosion.

4. Physical Fitness and Teamwork

Maintain excellent physical fitness to perform demanding tasks underwater.

- Work effectively as part of a team of divers and other professionals.

- Communicate clearly underwater using hand signals and voice communication systems.

Interview Tips

To ace your Underwater Welder interview, follow these key tips:

1. Research the Company and the Job

Familiarize yourself with the company’s background, operations, and the specific requirements of the job.

- Visit the company’s website and review their annual reports.

- Look for news articles and industry reports about the company.

2. Highlight Your Welding Skills and Experience

Emphasize your proficiency in underwater welding techniques, including your experience with different welding processes and materials.

- Quantify your accomplishments whenever possible, using specific numbers and examples.

- Be prepared to discuss your experience with underwater equipment and safety protocols.

3. Demonstrate Your Teamwork and Communication Abilities

Underwater welding often requires collaboration and clear communication. Highlight your ability to work effectively as part of a team.

- Share examples of how you have successfully collaborated with others on underwater projects.

- Explain how you maintain clear and effective communication underwater.

4. Prepare for Physical and Technical Challenges

Underwater welding is a physically demanding job. Be prepared to discuss your physical fitness and your ability to handle the challenges of working underwater.

- Describe your experience with diving and underwater welding in challenging conditions.

- Explain how you stay up-to-date with the latest welding technologies and safety practices.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Underwater Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.