Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wire Rigger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

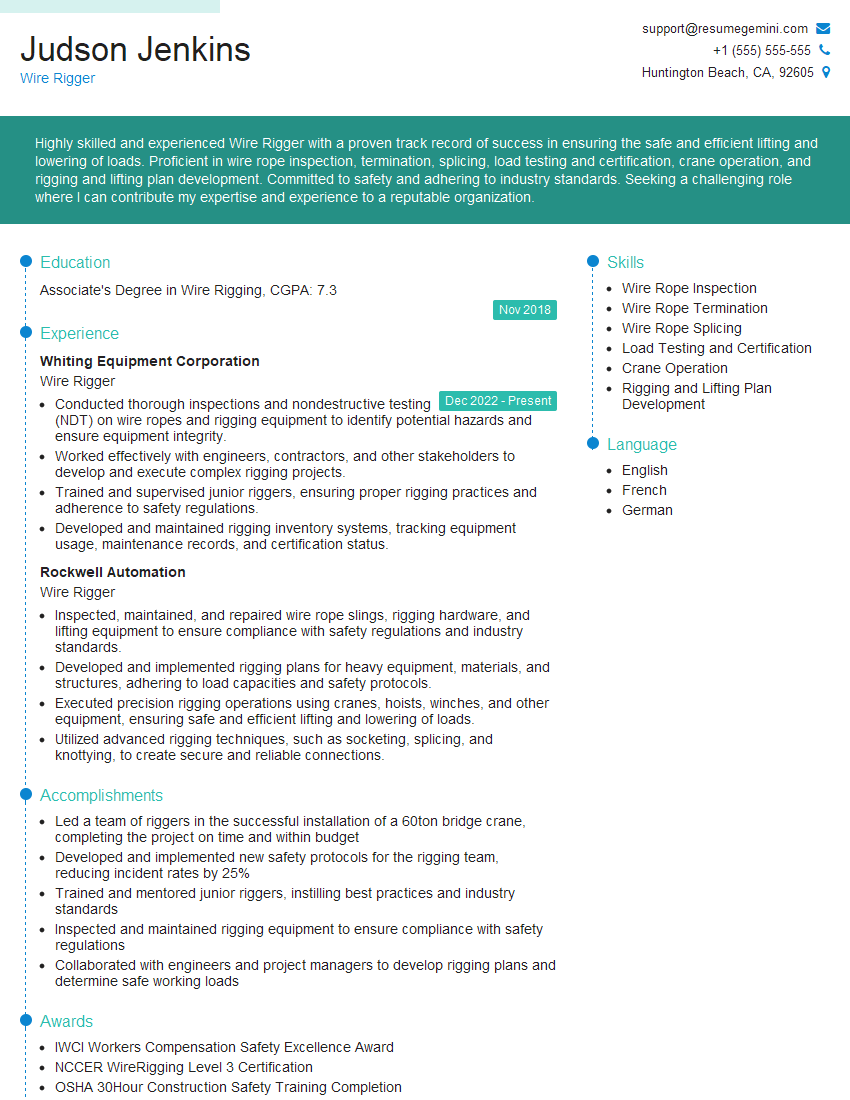

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wire Rigger

1. Describe the steps involved in rigging a load for lifting?

The steps involved in rigging a load for lifting are:

- Select the appropriate rigging equipment: Choose the correct slings, shackles, and other hardware based on the load’s weight, size, and shape.

- Inspect the rigging equipment: Ensure that all equipment is in good condition and free from damage.

- Attach the slings to the load: Secure the slings to the load using the appropriate hitches and knots.

- Attach the rigging equipment to the crane or hoist: Connect the slings to the crane’s or hoist’s lifting hook.

- Test the lift: Perform a test lift to ensure that the load is stable and secure.

- Lift the load: Once the test lift is successful, lift the load to the desired height.

2. What are the different types of slings used in wire rigging?

The different types of slings used in wire rigging include:

Wire rope slings

- Made from high-strength wire ropes

- Strong and durable

- Used for lifting heavy loads

Chain slings

- Made from alloy steel chains

- Strong and resistant to wear

- Used for lifting loads in harsh environments

Web slings

- Made from synthetic fibers such as nylon or polyester

- Lightweight and flexible

- Used for lifting loads that require gentle handling

3. What is the safe working load (SWL) of a wire rope sling?

The safe working load (SWL) of a wire rope sling is the maximum weight that the sling can safely lift. The SWL is determined by the size, grade, and construction of the wire rope sling.

4. What are the factors that affect the SWL of a wire rope sling?

The factors that affect the SWL of a wire rope sling include:

- Size of the wire rope

- Grade of the wire rope

- Construction of the wire rope sling

- Environmental conditions

- Frequency of use

5. What are the different types of wire rope terminations?

The different types of wire rope terminations include:

Spliced eye

- Created by splicing the ends of the wire rope together

- Strong and durable

- Used for lifting heavy loads

Mechanical socket

- Made of a metal socket that is crimped onto the wire rope

- Quick and easy to install

- Used for lighter loads

Swaged socket

- Similar to a mechanical socket, but the wire rope is swaged (compressed) into the socket

- Strong and durable

- Used for heavy loads

6. What are the safety precautions that should be taken when working with wire ropes?

The safety precautions that should be taken when working with wire ropes include:

- Inspect wire ropes regularly for damage

- Never overload wire ropes

- Use proper rigging techniques

- Wear appropriate safety gear

- Be aware of the surroundings

7. What are the different types of wire rope end fittings?

The different types of wire rope end fittings include:

Thimbles

- Used to protect the end of the wire rope from wear and tear

- Made of metal or plastic

- Available in various sizes and shapes

Wire rope clips

- Used to secure the end of the wire rope

- Made of metal

- Available in various sizes

Turnbuckles

- Used to adjust the tension of the wire rope

- Made of metal

- Available in various sizes

8. What are the different types of wire rope constructions?

The different types of wire rope constructions include:

1×19

- Single strand of 19 wires

- Flexible and easy to handle

- Used for light to medium loads

6×19

- Six strands of 19 wires each

- Stronger and more durable than 1×19

- Used for medium to heavy loads

8×19

- Eight strands of 19 wires each

- Strongest and most durable of the three constructions

- Used for heavy loads

9. What is the importance of proper wire rope maintenance?

Proper wire rope maintenance is important for ensuring the safety and reliability of the wire rope. Regular inspections and maintenance can help to identify and correct potential problems before they become major issues.

10. Describe the process of inspecting a wire rope for damage.

To inspect a wire rope for damage, follow these steps:

- Examine the wire rope for any visible signs of damage, such as broken wires, corrosion, or wear.

- Use a magnifying glass to inspect the wire rope for any small cracks or defects.

- Bend the wire rope to check for any stiffness or kinks.

- Listen for any unusual noises when bending the wire rope.

- Measure the diameter of the wire rope to check for any wear.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wire Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wire Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wire Rigger, also known as a Wire Rope Splicer or Cable Splicer is a skilled professional who specializes in the splicing, installation, and maintenance of wire ropes and cables.

1. Splicing and Repairing Wire Ropes and Cables

A Wire Rigger’s primary responsibility is to splice wire ropes and cables of various thicknesses and materials. They ensure that the splices meet the required specifications, strength, and safety standards.

- Inspect wire ropes and cables for damage, wear, and corrosion.

- Determine the appropriate splicing technique and materials based on the wire rope’s construction, diameter, and application.

- Prepare the wire rope ends by removing strands, cleaning, and shaping them.

- Splice the wire rope ends together using mechanical, hand-tucked, or poured spelter methods.

- Test the spliced joint’s strength and durability to ensure it meets the required specifications.

2. Installing and Maintaining Wire Rope Systems

Wire Riggers are also responsible for installing and maintaining wire rope systems in various applications, such as cranes, hoists, elevators, and bridges.

- Design and layout wire rope systems according to specifications and safety regulations.

- Install wire ropes and cables, including threading them through sheaves, pulleys, and other components.

- Inspect and maintain wire rope systems regularly, identifying and repairing any damage or wear.

- Lubricate and adjust wire ropes and cables to ensure smooth operation and extend their lifespan.

- Inspect and replace worn or damaged components, such as thimbles, turnbuckles, and shackles.

3. Ensuring Safety and Compliance

Wire Riggers play a critical role in ensuring the safety of wire rope systems and the people working with them.

- Follow established safety protocols and regulations while performing splicing and maintenance work.

- Inspect and certify wire rope systems to ensure they meet safety standards and regulations.

- Adhere to quality control procedures to ensure the integrity and reliability of their work.

4. Troubleshooting and Problem-Solving

Wire Riggers are expected to troubleshoot and resolve issues related to wire rope systems and their components.

- Identify and diagnose problems with wire ropes, cables, and related components.

- Determine the cause of failures and recommend corrective actions to prevent future occurrences.

- Work collaboratively with engineers and other professionals to find solutions to complex problems.

Interview Tips

Preparing for a Wire Rigger interview requires a combination of technical knowledge, understanding of the industry, and effective communication skills.

1. Research the Industry and Company

Familiarize yourself with the wire rigging industry, its standards, and the latest technologies used in the field.

- Review industry publications, attend webinars, and explore online resources.

- Research the company you’re applying to, its projects, and its safety record.

2. Practice Your Technical Skills

Demonstrate your proficiency in wire rope splicing, installation, and maintenance techniques.

- Review the different splicing methods and their applications.

- Practice splicing on different types of wire ropes and cables.

- Prepare examples of your work, such as photographs or project documentation.

3. Highlight Your Safety Knowledge

Emphasize your understanding of safety regulations and industry best practices.

- Review OSHA and industry safety standards related to wire rigging.

- Explain how you prioritize safety in your work and ensure compliance.

- Provide examples of your involvement in safety programs or initiatives.

4. Prepare for Common Interview Questions

Anticipate and prepare answers to common interview questions related to your experience, skills, and career goals.

- Can you describe your experience in splicing and maintaining wire ropes and cables?

- How do you ensure the safety of wire rope systems and those working around them?

- What are the different types of wire rope splicing methods and when would you use each one?

- Have you worked on any complex or challenging wire rigging projects?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wire Rigger, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wire Rigger positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.