Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Industrial Gas Service Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

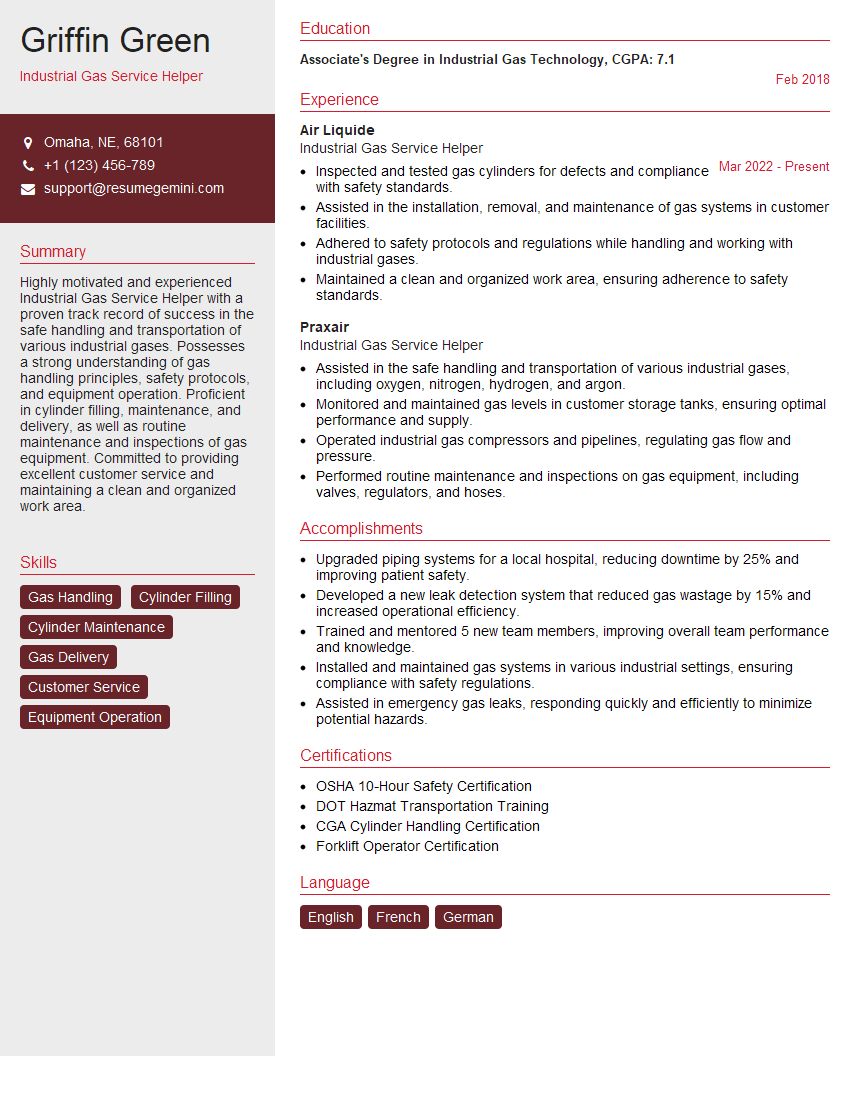

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Industrial Gas Service Helper

1. Describe the key responsibilities of an Industrial Gas Service Helper.

As an Industrial Gas Service Helper, my key responsibilities encompass various aspects of gas service operations. These include:

- Assisting with the installation, maintenance, and repair of industrial gas systems and equipment, ensuring their safe and efficient operation.

- Performing routine inspections and tests on gas equipment, monitoring its performance, and troubleshooting any potential issues.

- Providing technical support to customers, addressing their queries and resolving any service-related concerns promptly.

- Adhering to safety protocols and regulations related to the handling and storage of industrial gases.

- Maintaining a clean and organized work area, ensuring the proper disposal of waste and hazardous materials.

2. What are the different types of industrial gases used in various industries?

Inert Gases

- Argon: Used in welding, metal fabrication, and food processing.

- Nitrogen: Used in manufacturing, packaging, and electronics.

Reactive Gases

- Oxygen: Used in medical applications, welding, and steel production.

- Hydrogen: Used in fuel cells, fertilizers, and chemical processing.

Fuel Gases

- Acetylene: Used in welding and metal cutting.

- Propane: Used in heating, cooking, and industrial processes.

3. Explain the importance of proper handling and storage of industrial gases.

Proper handling and storage of industrial gases are crucial to ensure workplace safety and prevent potential hazards. Here’s why it’s important:

- Safety: Many industrial gases are flammable, toxic, or corrosive, posing risks to human health and the environment if not handled correctly.

- Efficiency: Proper storage helps maintain the quality and purity of gases, ensuring their effectiveness for intended applications.

- Regulatory Compliance: Industries must adhere to regulations and standards governing the storage and handling of hazardous substances, including industrial gases.

- Risk Mitigation: Appropriate storage and handling practices minimize the risk of leaks, explosions, or accidents, protecting employees, property, and the surrounding community.

4. Describe the safety measures and protocols you follow while working with industrial gases.

Safety is paramount when working with industrial gases. I adhere to the following measures and protocols:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, safety glasses, protective clothing, and respirators when necessary.

- Gas Detection and Monitoring: Use gas detectors to monitor gas levels and ensure they are within safe limits.

- Proper Ventilation: Ensure adequate ventilation in work areas to prevent gas buildup.

- Leak Detection and Repair: Regularly inspect equipment for leaks and promptly repair any detected issues.

- Emergency Response Plan: Familiarize myself with emergency response procedures and evacuation protocols in case of an accident.

5. Explain the role of pressure regulators and flow meters in industrial gas systems.

Pressure Regulators

- Control and reduce gas pressure to a safe and usable level.

- Ensure consistent gas flow and prevent pressure fluctuations.

Flow Meters

- Measure and monitor the flow rate of gases.

- Help optimize gas consumption and ensure accurate gas delivery.

6. Describe the process of purging a gas line.

Purging a gas line involves removing air, moisture, or contaminants from the line before introducing a specific gas.

- Mechanical Purging: Using an inert gas to physically push the existing gas out of the line.

- Chemical Purging: Using a chemical agent to react with and remove contaminants.

- Vacuum Purging: Creating a vacuum in the line to draw out the existing gas and contaminants.

7. Explain the importance of maintaining records and documentation in industrial gas service.

Records and documentation are vital in industrial gas service for several reasons:

- Safety and Compliance: Documenting inspections, maintenance, and repairs provides evidence of adherence to safety protocols and regulations.

- Quality Assurance: Records help track gas quality, ensuring it meets customer specifications.

- Troubleshooting: Documentation aids in identifying and resolving issues, reducing downtime and improving efficiency.

- Training and Knowledge Transfer: Records serve as a valuable resource for training new staff and sharing knowledge.

8. Describe the types of welding processes that use industrial gases.

- Gas Metal Arc Welding (GMAW): Uses a shielding gas, typically argon or carbon dioxide, to protect the weld pool from contamination.

- Gas Tungsten Arc Welding (GTAW): Employs an inert gas, such as argon, to shield the weld zone and prevent oxidation.

- Plasma Arc Cutting (PAC): Utilizes a plasma gas, usually argon or nitrogen, to create a high-temperature plasma for cutting metals.

9. Explain the principles of cryogenic gas handling.

Cryogenic gases are stored and handled at extremely low temperatures. Their handling requires special considerations:

- Specialized Equipment: Cryogenic gases are stored in insulated tanks and require special valves, hoses, and fittings.

- Temperature Control: Maintaining cryogenic temperatures is crucial to prevent gas loss and ensure safe handling.

- Safety Precautions: Working with cryogenic gases requires appropriate PPE and training to minimize risks, such as frostbite or asphyxiation.

10. Describe your experience in troubleshooting and repairing industrial gas equipment.

In my previous role, I was responsible for troubleshooting and repairing various industrial gas equipment, including:

- Diagnosing and fixing leaks in gas lines and equipment.

- Replacing faulty regulators, flow meters, and other components.

- Performing preventative maintenance to ensure optimal equipment performance.

- Collaborating with technicians to identify and resolve complex issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Industrial Gas Service Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Industrial Gas Service Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Industrial Gas Service Helper, you will play a vital role in supporting the efficient and safe operation of our organization. Your key responsibilities will include:

1. Assisting with Service and Delivery

• Assisting Gas Service Technicians with the installation, maintenance, and repair of industrial gas equipment

• Loading and unloading gas cylinders and equipment from delivery trucks and customer sites

• Operating forklifts and other equipment to transport and position gas cylinders and equipment

2. Customer Service and Support

• Providing excellent customer service to clients, answering questions and resolving issues related to gas products and services

• Assisting customers with the selection and ordering of gas products and services

• Maintaining a clean and organized work environment

3. Safety and Compliance

• Adhering to all safety regulations and procedures

• Wearing appropriate personal protective equipment (PPE)

• Maintaining a positive and collaborative work attitude

4. Equipment Maintenance

• Maintaining and servicing gas equipment

• Inspecting gas equipment for any leaks or damage

• Cleaning and storing gas equipment

Interview Tips

To prepare for your interview for the Industrial Gas Service Helper position, consider the following tips:

1. Research the Company and Position

• Familiarize yourself with the company’s website, history, and mission statement

• Learn about the specific duties and responsibilities of the Industrial Gas Service Helper role

2. Practice Your Answers

• Think about potential interview questions and prepare thoughtful responses

• Use the STAR method (Situation, Task, Action, Result) to structure your answers

3. Highlight Transferable Skills

• If you don’t have direct experience as an Industrial Gas Service Helper, emphasize transferable skills such as customer service, problem-solving, and teamwork

• Provide specific examples of how you have applied these skills in previous roles

4. Prepare Questions

• Prepare thoughtful questions to ask the interviewer about the company, the role, and the team

• Asking questions shows your interest and engagement

5. Dress Professionally

• Dress appropriately for the interview, typically business casual or formal attire

• Ensure your clothing is clean, pressed, and fits well

6. Be Punctual

• Punctuality shows respect for the interviewer’s time

• Plan your route and arrive a few minutes early

7. Follow Up

• Send a thank-you note to the interviewer within 24-48 hours

• In the note, reiterate your interest in the position and highlight any additional qualifications or experiences that you may not have had an opportunity to discuss during the interview

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Industrial Gas Service Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Industrial Gas Service Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.