Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blacksmith Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

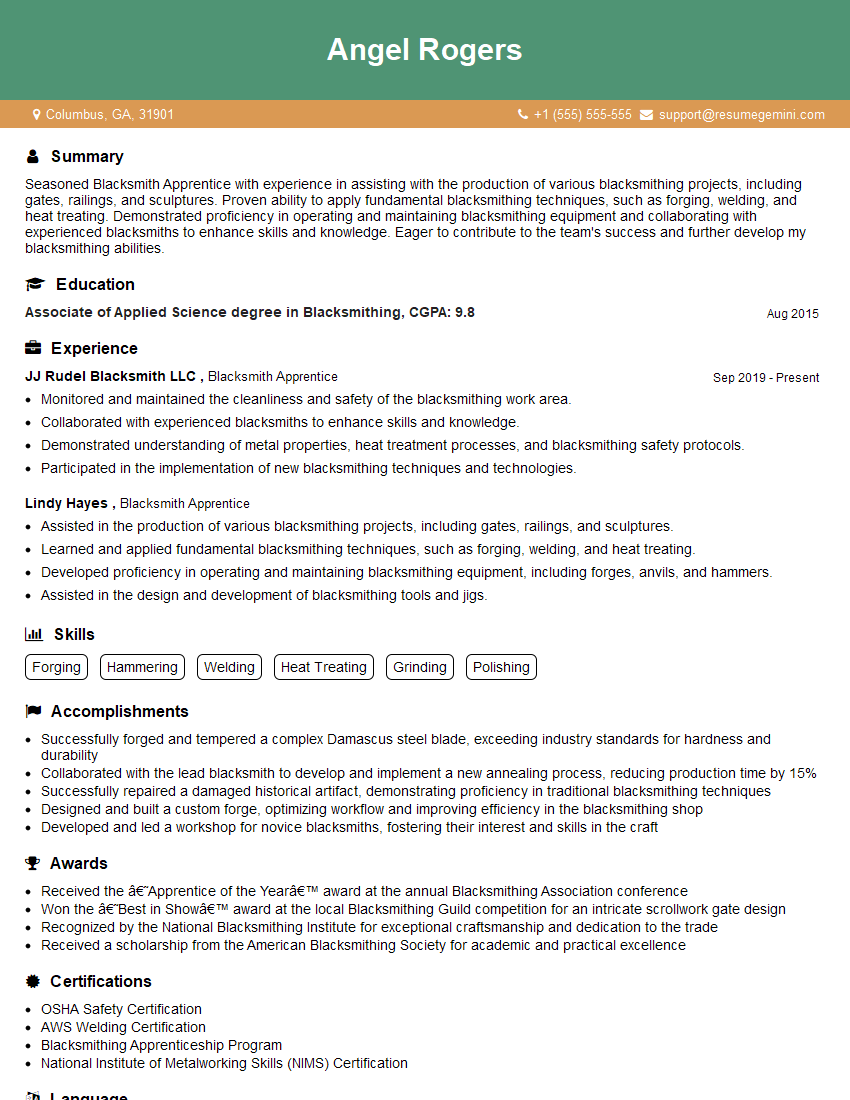

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blacksmith Apprentice

1. What are the different types of hammers used in blacksmithing?

There are several types of hammers used in blacksmithing, each designed for specific tasks:

- Hand Hammer: A versatile hammer used for general forging, shaping, and flattening.

- Cross Pein Hammer: One side is flat for flattening, while the other has a cross pein for shaping or punching.

- Ball Pein Hammer: A hammer with a rounded head used for riveting, texturing, or creating concave shapes.

- Sledgehammer: A large, heavy hammer used for heavy forging or splitting materials.

- Rounding Hammer: A hammer with a rounded head used for shaping and smoothing curves or edges.

2. How do you determine the correct temperature for forging different metals?

Color and Glow

- Steel: Non-luminous (dark red to yellow) for forging, luminous (white to yellow) for welding.

- Iron: Non-luminous (black to cherry red) for forging, luminous (orange to white) for welding.

Sparks

- Steel: Long, bright sparks when hot enough for forging.

- Iron: Short, dull sparks when hot enough for forging.

3. Describe the process of heat treating steel.

- Annealing: Heating the steel and slowly cooling it to soften and improve ductility.

- Hardening: Heating the steel to a critical temperature and rapidly cooling it (quenching) to increase hardness.

- Tempering: Reheating the hardened steel to a lower temperature and cooling it to reduce brittleness and improve toughness.

4. What are the safety hazards associated with blacksmithing?

- Heat: Burns from hot metal, forge, or anvil.

- Fire: Sparks and hot objects can ignite nearby materials.

- Eye Injuries: Sparks and flying metal chips.

- Hearing Loss: Loud noises from hammers and forging.

- Chemical Hazards: Fumes from welding and grinding.

5. What is the difference between forging and welding?

- Forging: Shaping metal by heating and hammering it, without melting it.

- Welding: Joining pieces of metal by heating them to the melting point and fusing them together.

6. How do you select the appropriate annealing temperature for steel?

- Consider the type of steel: Different types of steel have different critical temperatures.

- Check manufacturer’s recommendations: Refer to the data sheets for the specific steel you are using.

- Use a pyrometer or color chart: Measure or estimate the temperature of the steel.

7. Describe the process of tempering hardened steel.

- Reheat the hardened steel to a predetermined temperature: This reduces brittleness and improves toughness.

- Hold the steel at that temperature: The length of time depends on the desired hardness.

- Quench the steel: Rapidly cooling the steel in oil, water, or air to lock in the desired hardness.

8. What are the different types of welding joints used in blacksmithing?

- Butt Joint: Two pieces of metal are joined directly together, often with a filler material.

- Edge Joint: Two pieces of metal are overlapped and joined along their edges.

- T-Joint: One piece of metal is placed perpendicular to another and joined along their edges.

- Lap Joint: One piece of metal is overlapped on top of another and joined along their overlapping edges.

- Scarf Joint: Two pieces of metal are beveled at their edges and joined together.

9. How do you prevent oxidation on forged metal surfaces?

- Apply a protective coating: Wax, oil, or paint can seal out moisture and oxygen.

- Keep the metal dry: Store it in a moisture-free environment.

- Use a rust inhibitor: Apply a chemical treatment to prevent corrosion.

10. What is the role of a flux in blacksmithing?

- Clears oxides and impurities: A flux removes oxidation from metal surfaces, allowing for better welding and forging.

- Reduces surface tension: Flux helps the molten metal flow more easily.

- Prevents voids and flaws: Flux fills in gaps and prevents air pockets from forming during welding or forging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blacksmith Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blacksmith Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blacksmith Apprentice plays a crucial role in the blacksmithing process, serving as an assistant to experienced blacksmiths and performing various tasks. Their primary responsibilities include:

1. Assisting Blacksmiths

Assisting blacksmiths in forging, shaping, and finishing metal objects.

- Stoking the fire and regulating its temperature.

- Holding and moving heated metal while the blacksmith works on it.

- Using basic blacksmithing tools and equipment following instructions.

2. Operating and Maintaining Equipment

Operating and maintaining blacksmithing equipment, such as forge, anvil, hammers, and other tools.

- Cleaning and maintaining the workspace, equipment, and tools.

- Performing basic repairs and troubleshooting equipment malfunctions.

- Understanding the functionality and safety protocols of blacksmithing machinery.

3. Material Handling

Handling and managing different types of metal materials used in blacksmithing.

- Identifying and selecting metals based on specifications.

- Preparing and mixing alloys and fluxes as per instructions.

- Minimizing waste and optimizing material usage.

4. Safety and Compliance

Adhering to safety regulations and maintaining a clean and organized work environment.

- Wearing appropriate protective gear, including gloves, safety glasses, and fire-resistant clothing.

- Following established safety procedures for handling hot metal and equipment.

- Maintaining a clean and organized work area to prevent accidents and ensure efficiency.

Interview Tips

To ace the interview for a Blacksmith Apprentice position, candidates should prepare thoroughly and demonstrate their understanding of the trade, eagerness to learn, and passion for craftsmanship. Here are some key interview preparation tips:

1. Research the Trade and Company

Research the basics of blacksmithing, including common techniques, materials, and safety protocols.

- Explore the company’s website, social media, and industry publications to gain insights into their work, values, and culture.

- Familiarize yourself with the specific products or services offered by the company to demonstrate your interest in their business.

2. Highlight Relevant Skills and Experience

Emphasize your practical skills, such as metalworking, welding, or forging experience, even if it’s not directly in blacksmithing.

- Showcase your ability to work safely with tools and equipment, especially in a workshop or industrial setting.

- Highlight your attention to detail, precision, and commitment to producing quality work.

3. Showcase Your Passion and Eagerness to Learn

Express your passion for metalworking and craftsmanship, and demonstrate your willingness to learn new techniques and skills.

- Share examples of personal projects or hobbies that demonstrate your interest in blacksmithing or related crafts.

- Ask thoughtful questions about the apprenticeship program, training opportunities, and career advancement within the company.

4. Prepare Questions for the Interviewer

Preparing questions for the interviewer shows your engagement and enthusiasm for the role.

- Inquire about the day-to-day responsibilities of the apprentice and the typical career path.

- Ask about the company’s commitment to training and development for apprentices.

Next Step:

Now that you’re armed with the knowledge of Blacksmith Apprentice interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Blacksmith Apprentice positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini