Are you gearing up for a career in Chain Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Chain Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

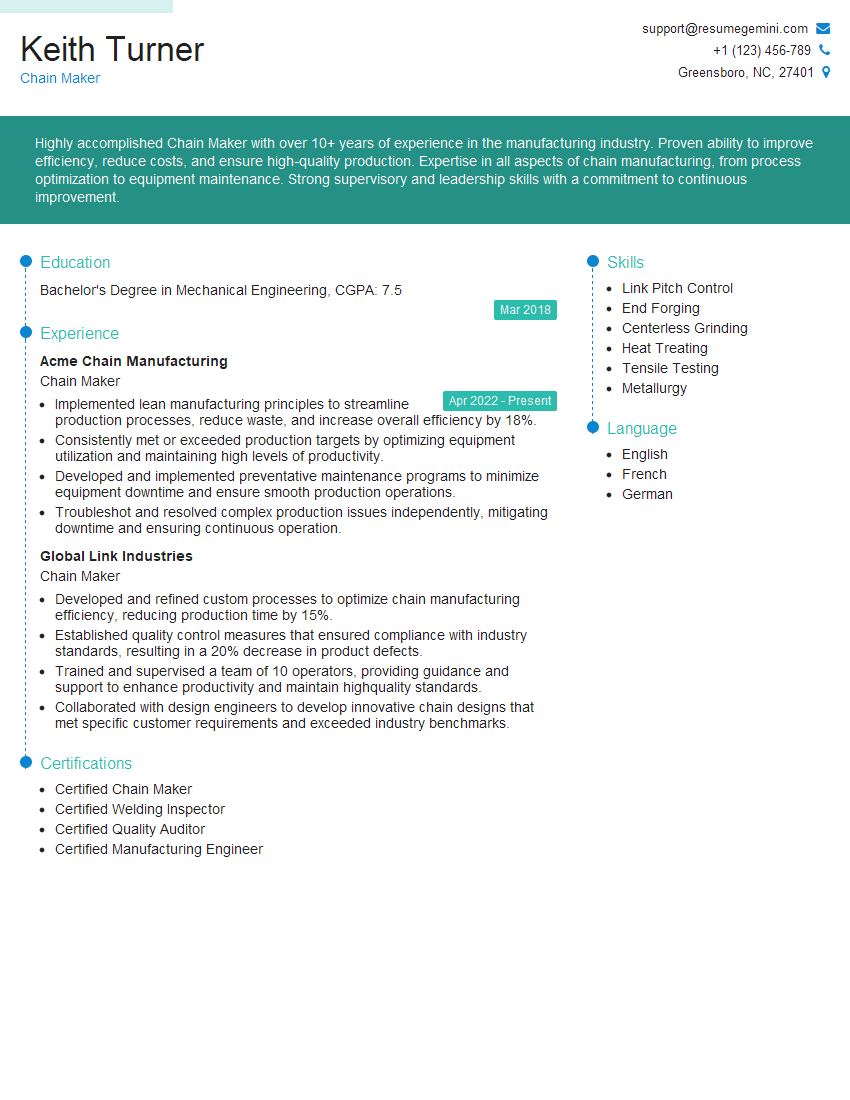

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chain Maker

1. What are the essential steps in the chain-making process?

The chain-making process involves several crucial steps to produce high-quality chains:

- Wire Drawing: Drawing metal rods into wires of desired thickness and diameter using specialized machinery.

- Annealing: Heating and cooling the wire to improve its ductility and workability.

- Forming: Shaping the wire into the desired chain link configuration using bending tools or dies.

- Welding: Joining the formed links together using welding techniques such as resistance welding or laser welding.

- Finishing: Applying surface treatments like plating, polishing, or coating to enhance the chain’s appearance and durability.

2. Describe the different types of chain drives and their applications.

Chain and Sprocket Drives

- Used for transmitting power between parallel shafts.

- Types: Roller chains, silent chains, timing chains.

- Applications: Industrial machinery, automotive engines.

Chain Hoists

- Used for lifting heavy objects.

- Types: Manual chain hoists, electric chain hoists.

- Applications: Construction sites, warehouses.

Bicycle Chains

- Used to transmit power from the pedals to the rear wheel.

- Types: Single-speed chains, multi-speed chains.

- Applications: Bicycles.

3. Which factors determine the strength and durability of a chain?

- Material Selection: Choosing the appropriate metal alloy for the chain’s intended application.

- Heat Treatment: Hardening and tempering processes to enhance the chain’s strength and wear resistance.

- Link Design: Optimizing the shape and dimensions of the links for maximum strength and flexibility.

- Welding Quality: Ensuring proper welding techniques and weld penetration to create strong joints.

- Surface Treatments: Applying corrosion-resistant coatings or plating to protect the chain from environmental factors.

4. What are the common problems encountered in chain-making and how do you resolve them?

- Chain Breakage: Inspect for weak links, excessive wear, or improper welding.

- Chain Stretch: Monitor chain tension regularly and adjust it if necessary to prevent elongation.

- Corrosion: Apply corrosion-resistant treatments or use chains made from corrosion-resistant materials.

- Link Misalignment: Ensure proper alignment of the links during assembly and welding.

- Lubrication Issues: Lubricate the chain regularly to reduce friction and wear.

5. How do you maintain and inspect chains to ensure their longevity?

- Regular Inspection: Visually inspect chains for wear, damage, or corrosion.

- Cleaning: Remove dirt, grease, and other contaminants using appropriate cleaning agents.

- Lubrication: Apply lubricant to reduce friction and wear.

- Tension Adjustment: Monitor chain tension and adjust it as necessary to prevent stretch or breakage.

- Replacement: Replace worn or damaged chains promptly to maintain optimal performance.

6. What are the different types of materials used in chain manufacturing and their advantages?

- Carbon Steel: Strong, durable, and cost-effective.

- Alloy Steel: Higher strength and wear resistance than carbon steel.

- Stainless Steel: Corrosion-resistant and ideal for applications where hygiene is crucial.

- Nickel-Plated Steel: Enhanced corrosion resistance and aesthetics.

- Plastic: Lightweight, low-maintenance, and suitable for non-critical applications.

7. How do you calculate the appropriate chain size and length for a specific application?

- Load Capacity: Determine the maximum load the chain will carry.

- Speed: Consider the operating speed of the chain.

- Pitch: The distance between the centers of adjacent pins.

- Length: Measure the distance between the sprocket centers or the desired length of the chain.

- Environmental Conditions: Account for factors like temperature, humidity, and corrosion.

8. Describe the principles of heat treatment applied to chains.

- Annealing: Heating and slowly cooling the chain to soften it.

- Hardening: Heating the chain to a high temperature and then rapidly cooling it to increase its hardness.

- Tempering: Reheating the chain to a specific temperature below the hardening temperature to improve its toughness.

- Carburizing: Adding carbon to the chain’s surface to enhance its hardness and wear resistance.

9. How do you ensure quality control in chain manufacturing?

- Raw Material Inspection: Inspecting incoming materials for compliance with specifications.

- Process Monitoring: Regularly checking critical parameters during the manufacturing process.

- Non-Destructive Testing: Using methods like magnetic particle inspection and ultrasonic testing to detect defects.

- Dimensional Inspection: Ensuring that chains meet the specified dimensions.

- Tensile Strength Testing: Testing chains to verify their strength and load-bearing capacity.

10. What are the ethical considerations in the chain-making industry?

- Environmental Sustainability: Adhering to regulations and practices that minimize environmental impact.

- Worker Safety: Ensuring proper safety measures and equipment for employees.

- Fair Labor Practices: Complying with labor laws and promoting fair working conditions.

- Product Responsibility: Manufacturing chains that meet safety and performance standards.

- Customer Satisfaction: Prioritizing customer satisfaction and addressing any concerns promptly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chain Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chain Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chain makers are skilled workers who create chains for a variety of purposes, including jewelry, hardware, and industrial applications.

1. Manufacturing Chains

Chain makers operate machines that produce chains of different sizes, shapes, and materials. They ensure that the chains are made to the required specifications and quality standards.

- Set up and operate chain-making machines

- Monitor the production process to ensure that the chains are made to the correct specifications

- Adjust the machines as needed to maintain optimal performance

2. Inspecting Chains

Chain makers inspect the finished chains to ensure that they meet the required quality standards. They check for defects, such as broken links or uneven spacing, and make any necessary repairs.

- Inspect the chains for defects

- Repair any defects that are found

- Make sure that the chains meet the required quality standards

3. Maintaining Equipment

Chain makers perform routine maintenance on their machines to ensure that they are operating properly and safely. They also clean and lubricate the machines as needed.

- Perform routine maintenance on chain-making machines

- Clean and lubricate the machines

- Inspect the machines for any signs of wear or damage

4. Quality Assurance

Chain makers are involved in all aspects of quality assurance, from inspecting the raw materials to testing the finished chains. They work to ensure that the chains meet the highest standards of quality.

- Inspect the raw materials to ensure that they meet the required specifications

- Test the finished chains to ensure that they meet the required quality standards

Interview Tips

Preparing for a chain maker interview can help you make a positive impression on the hiring manager and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the Company

Before your interview, take some time to research the company you’re applying to. This will help you understand their business, values, and culture. It will also help you answer questions about the company in a more informed way.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people you know who work for the company

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?” Practice answering these questions in a clear and concise way.

- Use the STAR method to answer behavioral questions

- Be prepared to talk about your experience and skills

- Practice answering questions about your goals and aspirations

3. Be Prepared to Show Your Skills

If you have any relevant skills, such as machine operation or chain inspection, be prepared to demonstrate them during your interview. This could involve bringing a portfolio of your work or giving a presentation about your experience.

- Bring a portfolio of your work to the interview

- Be prepared to give a presentation about your experience

- Practice your skills so that you can demonstrate them confidently

4. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Avoid wearing revealing or distracting clothing

5. Be Punctual

Punctuality shows that you’re respectful of the interviewer’s time. Arrive for your interview on time, or even a few minutes early.

- Leave yourself plenty of time to get to the interview

- If you’re running late, call the interviewer and let them know

- Don’t be late

By following these tips, you can prepare for your chain maker interview and increase your chances of getting the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chain Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.