Are you gearing up for a career in Casting Repairer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Casting Repairer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

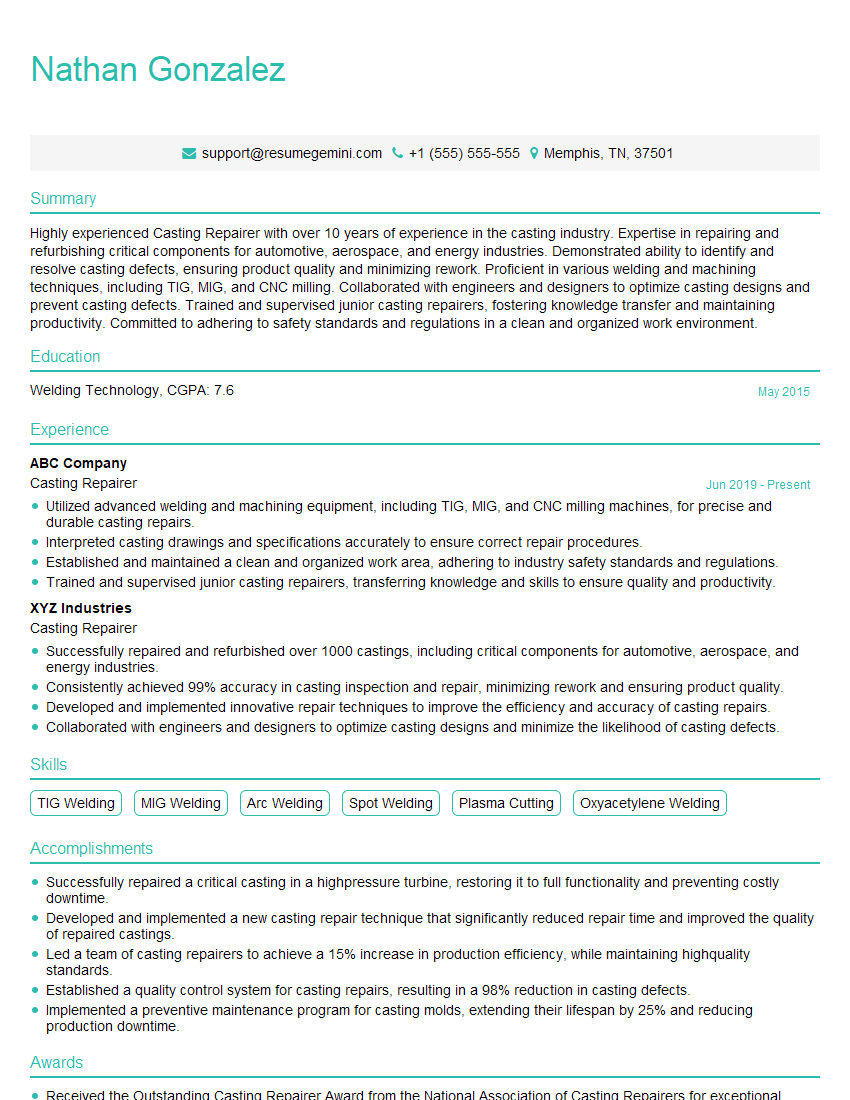

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casting Repairer

1. Describe the process of repairing a cracked casting?

The process of repairing a cracked casting involves several steps:

- Inspection: The casting is thoroughly inspected to determine the extent and location of the crack.

- Preparation: The area around the crack is cleaned and prepared to ensure proper adhesion of the repair material.

- Crack Repair: The crack is filled with a suitable material, such as epoxy or welding, to restore structural integrity.

- Grinding and Finishing: The repaired area is ground and finished to match the original casting surface.

2. What are the different types of welding techniques used in casting repair?

TIG (Tungsten Inert Gas) Welding:

- Produces high-quality welds with minimal distortion.

- Suitable for repairing small cracks and thin sections.

MIG (Metal Inert Gas) Welding:

- Faster and more efficient than TIG welding.

- Suitable for repairing larger cracks and thicker sections.

Arc Welding:

- Versatile and cost-effective technique.

- Suitable for repairing large cracks and heavy castings.

Electrode Welding:

- Relatively simple and portable technique.

- Suitable for repairing cracks in remote or inaccessible locations.

3. What are the key factors to consider when selecting a repair material for a cracked casting?

- Material Properties: Strength, hardness, and corrosion resistance of the material.

- Compatibility: Compatibility with the base material to ensure proper adhesion and performance.

- Weldability: Ability of the material to be welded or bonded to the casting.

- Application Environment: Temperature, humidity, and other environmental factors that may affect the repair’s longevity.

4. How do you ensure the quality of a casting repair?

- Proper Inspection: Thorough inspection before and after repair to identify any defects.

- Skilled Craftsmanship: Experienced and qualified technicians perform the repairs.

- Quality Control Standards: Adherence to established quality control standards and industry best practices.

- Testing: Non-destructive testing (NDT) methods, such as radiography or ultrasound, to verify the integrity of the repair.

5. Describe the importance of heat treatment in the casting repair process.

- Stress Relief: Heat treatment helps relieve stresses introduced during the welding process, preventing future cracking.

- Hardness Control: Controlled heat treatment can adjust the hardness of the repaired area to match the original casting.

- Structural Integrity: Proper heat treatment ensures the repaired casting maintains its structural integrity and performance.

6. What are the potential risks associated with casting repair?

- Incomplete Penetration: Inadequate penetration of the weld into the casting, leading to weak bonds and potential failure.

- Gas Entrapment: Trapped gases during welding can create voids and weaken the repair.

- Heat Distortion: Excessive heat during welding can cause warping or distortion of the casting.

- Corrosion: Improper surface preparation or choice of repair material can lead to corrosion around the repaired area.

7. How do you handle complex casting repair jobs involving multiple cracks or damaged areas?

- Prioritize Repairs: Determine the most critical cracks and repair them first to prevent further damage.

- Plan the Sequence: Establish a systematic approach to repairing cracks in a logical order to avoid additional stresses.

- Use Specialized Techniques: Employ advanced techniques, such as plasma welding or laser repair, for challenging repairs.

- Collaboration: Involve skilled fabricators or engineers as needed to address any complex design modifications.

8. What is the role of ultrasonic testing in the casting repair process?

- Crack Detection: Ultrasonic testing (UT) uses sound waves to detect cracks and other internal defects.

- Bond Evaluation: UT can evaluate the bond between the casting and the repair material, ensuring its integrity.

- Quality Control: UT provides a non-destructive method to assess the quality of the repair and monitor its performance over time.

9. Describe the importance of proper documentation in casting repair.

- Tracking Repairs: Detailed documentation records the repair process, including methods used, materials applied, and inspection results.

- Quality Assurance: Documentation provides evidence of quality control and compliance with industry standards.

- Historical Reference: Maintained records allow for easy reference and analysis of previous repairs, aiding in future troubleshooting and predictive maintenance.

10. How do you stay up-to-date with the latest advancements in casting repair techniques?

- Industry Conferences: Attend industry events and conferences to learn about new technologies and best practices.

- Professional Development: Participate in training programs, workshops, and certification courses to enhance skills and knowledge.

- Technical Publications: Read industry publications, technical articles, and case studies to stay informed about emerging trends.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casting Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casting Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casting Repairers play a critical role in the manufacturing process. They use specialized techniques to repair and restore damaged castings, ensuring that they meet the required quality standards. Their primary responsibilities include:

1. Repairing Defects

Identifying and repairing defects in castings, such as cracks, voids, or inclusions. This involves using various repair methods, including welding, grinding, and machining.

2. Restoring Functionality

Restoring the functionality of repaired castings by ensuring that they meet the original design specifications. This may involve replacing damaged components, adjusting tolerances, or performing other necessary modifications.

3. Quality Control

Inspecting and testing repaired castings to ensure they meet the required quality standards. This includes conducting non-destructive testing, dimensional inspection, and functional testing.

4. Documentation

Maintaining accurate records of repair operations, including the nature of the defect, the repair method used, and the results of quality control tests.

Interview Preparation Tips

To ace the interview for a Casting Repairer position, candidates should thoroughly prepare and highlight their skills and experience. Here are some tips to help them succeed:

1. Research the Company and Position

Gather information about the company’s industry, products, and culture. Review the job description carefully and identify the key requirements and responsibilities of the Casting Repairer role.

2. Highlight Relevant Skills and Experience

Emphasize their practical experience in casting repair techniques, such as welding, grinding, and machining. Showcase their ability to identify and repair defects, as well as their knowledge of quality control standards and testing procedures.

3. Showcase Problem-Solving Abilities

Provide examples of how they approached and solved complex casting repair challenges. Highlight their analytical and decision-making skills, and demonstrate their ability to work independently and as part of a team.

4. Prepare for Technical Questions

Study basic metallurgy and casting principles. Be prepared to answer questions about common defects in castings, repair methods, and quality control techniques. Review industry standards and best practices to demonstrate their technical proficiency.

5. Practice Interview Questions

Rehearse answering common interview questions related to their skills, experience, and career goals. Prepare specific examples and quantifiable results to support their answers and demonstrate their value to the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Casting Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.