Feeling lost in a sea of interview questions? Landed that dream interview for Pressure Sealer and Tester but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Pressure Sealer and Tester interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

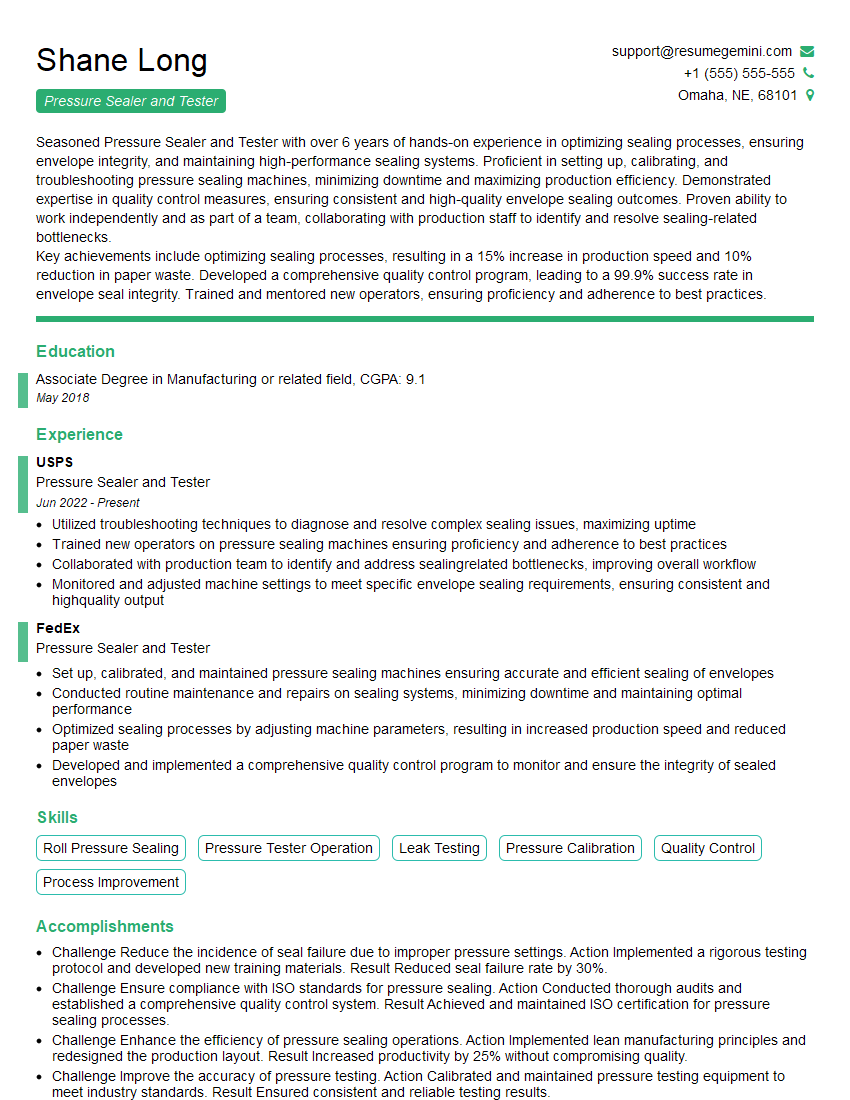

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pressure Sealer and Tester

1. Can you explain the key differences between hot melt and cold glue pressure sealers?

Answer:

- Hot melt sealers use heated glue, which cools and bonds when applied to the paper. They offer a strong and durable seal, but can be slower and require more maintenance.

- Cold glue sealers use a water-based adhesive that dries and bonds at room temperature. They are generally faster and easier to maintain, but may not provide as strong a seal as hot melt sealers.

2. What are the critical parameters to monitor and control when operating a pressure sealer?

Temperature and Pressure

- For hot melt sealers, it’s essential to maintain the correct temperature to ensure optimal glue flow and bonding.

- Pressure must be carefully controlled to prevent damage to the paper or envelopes and to ensure a consistent seal.

Feeder and Stacker Settings

- Proper feeder settings ensure smooth and accurate envelope feeding into the sealer.

- Stacker settings determine the quality of the sealed output, preventing jams or misalignments.

3. How do you troubleshoot a pressure sealer that is producing inconsistent or poorly sealed envelopes?

Answer:

- Check for any blockages or debris in the glue path.

- Verify the temperature and pressure settings are correct for the type of paper and glue being used.

- Inspect the feeder and stacker to ensure proper operation and alignment.

- Examine the paper for any damage or irregularities.

4. What are the common maintenance procedures for a pressure sealer?

Answer:

- Regular cleaning of the glue system to prevent buildup.

- Lubrication of moving parts to reduce wear and tear.

- Inspection and replacement of worn or damaged parts.

- Calibration of the machine to ensure accuracy and consistency.

5. How do you ensure the safety of operators when working with a pressure sealer?

Answer:

- Follow proper lockout/tagout procedures before servicing or repairing the sealer.

- Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Be aware of potential hazards such as hot glue or moving parts.

- Receive proper training and follow all safety guidelines provided.

6. What experience do you have with different types of pressure sealers and adhesives?

Answer:

- I have worked with both hot melt and cold glue pressure sealers.

- I am familiar with various types of adhesives, including water-based, solvent-based, and acrylic-based.

- I understand the strengths and limitations of each type and can select the appropriate adhesive for the job.

7. How do you stay up-to-date on the latest advancements in pressure sealing technology?

Answer:

- Attend industry conferences and trade shows.

- Read trade publications and online resources.

- Consult with industry experts and manufacturers.

- Continuously research and explore new technologies to improve efficiency and production.

8. Can you describe a time when you had to overcome a challenging situation related to pressure sealing?

Answer:

- Once, I encountered an issue with a pressure sealer that was producing inconsistent seals.

- I systematically troubleshoot the issue, checking the temperature, pressure, feeder settings, and paper quality.

- I identified a faulty sensor that was causing fluctuations in pressure, leading to inconsistent seals.

- I replaced the sensor, recalibrated the machine, and the problem was resolved.

9. What is your approach to quality control when it comes to pressure sealing?

Answer:

- Establish clear quality standards and specifications.

- Regularly inspect and test sealed envelopes to ensure they meet the required standards.

- Implement statistical process control techniques to monitor and improve quality.

- Train operators on quality control procedures and hold them accountable for maintaining high standards.

10. How do you handle high-volume pressure sealing operations efficiently?

Answer:

- Optimize the workflow to reduce bottlenecks.

- Utilize automated equipment and technology to streamline operations.

- Implement batch processing to increase efficiency.

- Provide comprehensive training to operators to ensure they can perform tasks quickly and accurately.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pressure Sealer and Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pressure Sealer and Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Pressure Sealer and Tester is responsible for ensuring the quality and accuracy of pressure-sealed mailings. They operate pressure sealing equipment to seal envelopes and other mail pieces, and they test the seals to make sure they meet the required standards.

1. Operate pressure sealing equipment

Pressure Sealer and Testers must be able to operate a variety of pressure sealing equipment, including high-speed machines that can seal thousands of envelopes per hour. They must be able to set up and adjust the equipment, and they must be able to troubleshoot any problems that may occur.

2. Test the seals

Pressure Sealer and Testers must be able to test the seals on envelopes and other mail pieces to make sure they meet the required standards. They may use a variety of methods to test the seals, including visual inspection, pressure testing, and leak testing.

3. Maintain records

Pressure Sealer and Testers must be able to maintain records of their work. These records may include information about the equipment they used, the materials they sealed, and the results of their tests.

4. Train new employees

Pressure Sealer and Testers may be responsible for training new employees on how to operate pressure sealing equipment and how to test seals. They must be able to explain the procedures clearly and they must be able to answer any questions that the new employees may have.

Interview Tips

Preparing for an interview for a Pressure Sealer and Tester position can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company

Before you go on an interview, it’s important to do your research on the company. This will help you understand the company’s culture and values, and it will also help you answer questions about the company’s products and services.

2. Practice your answers

Once you’ve done your research, you should practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or business casual attire.

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you’re running late, call the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during the interview. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just relax and be confident, and let the interviewer see the real you.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Pressure Sealer and Tester role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.