Are you gearing up for an interview for a Tool Adjuster position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tool Adjuster and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

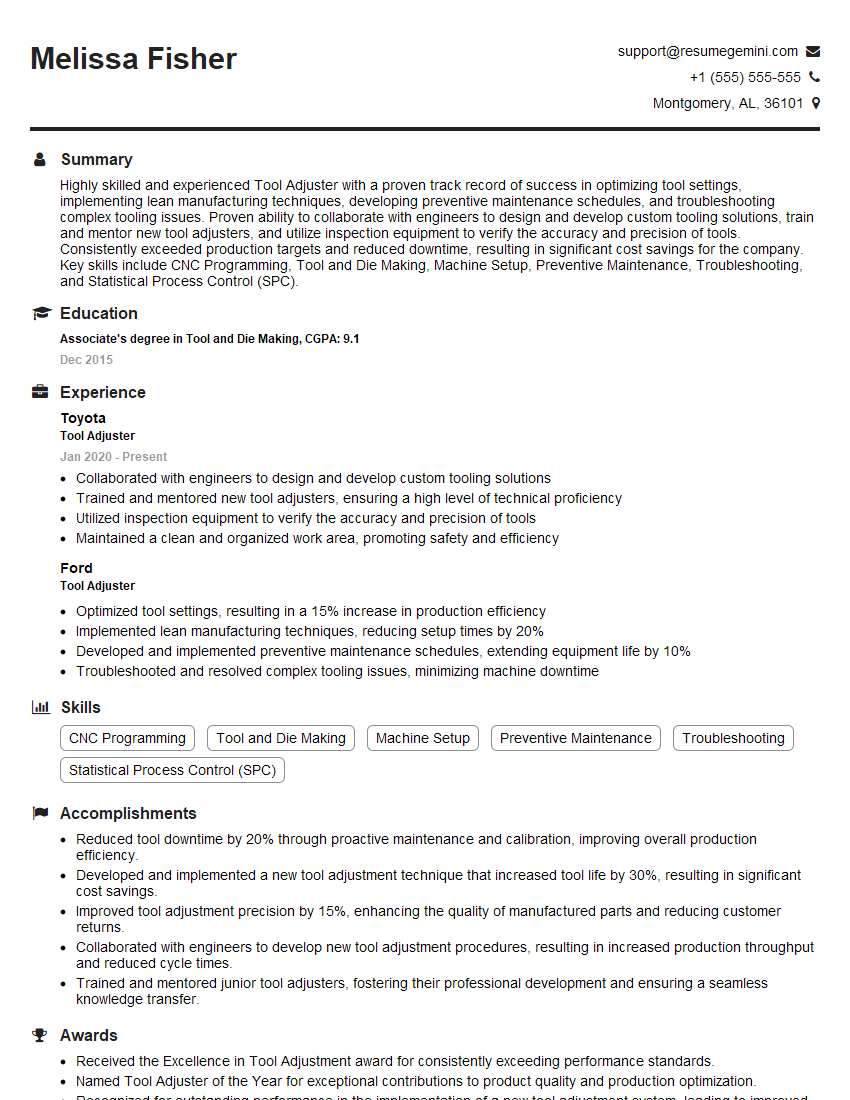

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Adjuster

1. Explain the process of tramming a milling machine?

Tramming a milling machine involves aligning the spindle axis with the table surface to ensure accurate machining operations. The process typically involves the following steps:

- Mount an indicator on the spindle: This is done by installing a dial indicator in the spindle holder or chuck.

- Lower the spindle: Lower the spindle until the indicator tip comes into contact with the table surface.

- Rotate the spindle by hand: Slowly rotate the spindle by hand while observing the indicator reading. The goal is to achieve zero runout, meaning the indicator needle should not move as the spindle rotates.

- Adjust the gibs: If there is runout, adjust the gibs on the table to bring the indicator reading to zero. The gibs control the movement of the table relative to the spindle.

- Repeat until zero runout is achieved: Continue rotating the spindle and adjusting the gibs until the indicator shows zero runout throughout the entire travel range of the table.

- Lock the gibs: Once zero runout is achieved, tighten the gib locks to maintain the alignment.

2. What are the key differences between manual and CNC tool adjustment?

Manual Tool Adjustment

- Requires skilled operators with a deep understanding of machine tools and cutting processes.

- Involves physically adjusting tools by hand using wrenches or other tools.

- Can be time-consuming, especially for complex setups.

- Relies heavily on the operator’s experience and expertise.

CNC Tool Adjustment

- Uses computer-aided technology to control tool adjustments.

- Involves programming the CNC machine with the necessary tool offsets and parameters.

- Automated and precise, reducing the risk of errors.

- Faster and more efficient for repetitive or complex tool adjustments.

3. Describe the different types of cutting tools used in milling operations and their applications?

- End mills: Used for a wide range of milling operations, including flat surfacing, slotting, and contouring.

- Face mills: Designed for high-speed machining of flat surfaces, providing high material removal rates.

- Side mills: Used for cutting slots, keyways, and other features with perpendicular sides.

- Ball mills: Used for contouring, 3D profiling, and creating complex shapes.

- Fly cutters: Used for machining large flat surfaces or irregular shapes.

4. How do you ensure the accuracy of tool offsets when adjusting tools?

- Use precision measuring tools: Utilize calipers, micrometers, or height gauges to accurately measure tool dimensions and offsets.

- Inspect and clean tools before use: Ensure that tools are clean and free of damage that could affect accuracy.

- Follow proper tool adjustment procedures: Adhere to established guidelines and protocols for setting tool offsets.

- Double-check measurements: Verify the accuracy of tool offsets by repeating measurements or using multiple measuring methods.

- Use tool presetting devices: Utilize specialized equipment designed to precisely set tool offsets before installation in the machine.

5. Explain the concept of tool life and how it relates to tool adjustment?

Tool life refers to the amount of time or number of operations a cutting tool can perform effectively before it needs to be replaced or resharpened. Tool adjustment plays a crucial role in extending tool life:

- Proper cutting conditions: Ensuring the correct tool offsets and cutting parameters helps optimize tool performance and reduce wear.

- Reduced tool stress: Precise tool alignment and adjustments minimize excessive forces on the tool, extending its service life.

- Prevention of premature failure: Regular tool adjustments help detect and correct tool wear or damage, preventing catastrophic failures that can damage the workpiece or machine.

6. How do you handle situations when tools break during machining operations?

- Immediately stop the machine: Ensure safety by powering down the machine as soon as a tool breaks.

- Inspect the tool and workpiece: Examine the broken tool and workpiece for damage or debris.

- Identify the cause of failure: Determine the potential causes of the tool breakage, such as excessive tool wear, incorrect settings, or material defects.

- Take corrective actions: Replace the broken tool, adjust cutting parameters or machine settings, or consult with supervisors if necessary.

- Maintain accurate records: Document the tool breakage incident, including the date, time, tool type, and suspected cause.

7. Describe how you would maintain and calibrate precision measuring tools used for tool adjustment?

- Regular cleaning: Clean tools regularly to remove dirt, debris, or cutting fluids that could affect accuracy.

- Calibration and verification: Calibrate tools periodically against certified standards or traceable references to ensure their accuracy and reliability.

- Proper storage: Store measuring tools in a clean, dry, and controlled environment to prevent damage or loss of calibration.

- Training and supervision: Provide training to operators on the proper use and maintenance of precision measuring tools.

- Recordkeeping: Maintain records of calibrations and inspections to track the status and history of measuring tools.

8. What are your experiences with using different types of tool presetters?

I have experience using various types of tool presetters, including mechanical, optical, and laser-based systems. Each type has its advantages and applications:

- Mechanical presetters: Accurate and reliable, suitable for general-purpose tool setting.

- Optical presetters: Provide highly precise tool measurement and alignment capabilities.

- Laser presetters: Offer non-contact measurement and can handle a wide range of tool geometries.

- Selection and application: I consider the accuracy requirements, tool sizes, and production volume when selecting and applying the appropriate tool presetter.

9. How do you ensure that tools are properly balanced before installation in the machine?

- Visual inspection: Check for any obvious signs of imbalance, such as uneven weight distribution or bent tool shanks.

- Balancing machine: Utilize a dedicated balancing machine to measure and correct imbalances in rotating tools.

- Static balancing: Use a simple balancing stand to check for static imbalances and make adjustments by adding or removing weight.

- Dynamic balancing: Perform dynamic balancing at the operating speed of the machine to eliminate both static and dynamic imbalances.

- Maintenance records: Keep records of balancing operations and any corrective actions taken.

10. What software or systems do you use to manage tool data and offsets?

- CAM software: Utilize CAM software to generate tool paths and manage tool data, including offsets, cutting parameters, and tool life information.

- Tool management systems: Implement specialized software or systems to centralize and manage tool data, track tool usage, and optimize tool life.

- CNC machine controllers: Use the CNC machine controller to store and recall tool offsets, allowing for efficient tool changes and adjustments.

- Cloud-based platforms: Explore cloud-based tool management platforms that provide real-time data and remote access to tool information.

- Integration and automation: Integrate tool management systems with other software and equipment to automate tool data transfer and optimize production processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Adjusters are responsible for setting up, maintaining, and troubleshooting production equipment used in manufacturing processes.

1. Equipment Setup and Maintenance

Tool Adjusters collaborate with mechanical engineering and production planning teams to ensure the accuracy and efficiency of production processes. They assemble and install tools and equipment, making adjustments to achieve optimal performance and quality standards. They also maintain equipment, perform routine inspections, and identify and resolve any issues to maximize productivity and prevent breakdowns.

2. Quality Assurance

Tool Adjusters are responsible for ensuring that the tools and equipment they handle meet the required quality standards. They conduct inspections and tests, monitor production processes, and make adjustments to ensure that products meet specifications and customer requirements.

3. Troubleshooting and Problem-Solving

When production problems arise, Tool Adjusters are responsible for identifying the root cause and implementing solutions. They analyze issues, identify defective components, and determine the necessary actions to restore production efficiency. They work closely with other departments, such as maintenance and production, to resolve issues in a timely manner.

4. Continuous Improvement

Tool Adjusters play a role in continuous improvement efforts within the manufacturing organization. They observe and analyze production processes, identify areas for improvement, and suggest enhancements to increase efficiency, accuracy, and quality. They collaborate with other teams to find innovative solutions to improve the overall performance of the production system.

Interview Tips

To ace an interview for a Tool Adjuster position, candidates should prepare thoroughly and demonstrate their skills and experience.

1. Research the Company and Industry

Before the interview, candidates should thoroughly research the company and the industry to understand their business, products, and market position. This knowledge will enable them to ask informed questions, demonstrate their interest in the role, and show that they are well-prepared for the interview.

2. Highlight Relevant Skills and Experience

During the interview, candidates should emphasize their technical skills and experience in equipment setup, maintenance, troubleshooting, and quality assurance. They should provide specific examples of their work and the impact they have had on production processes. It is important to tailor their answers to the specific requirements of the job description.

3. Demonstrate Problem-Solving Abilities

Tool Adjusters should be able to think critically and solve problems effectively. Interviewers often ask questions about how candidates have handled challenging situations in the past. Candidates should be prepared to share examples where they identified and resolved production issues, improved efficiency, or found innovative solutions to enhance production processes.

4. Emphasize Attention to Detail

Attention to detail is crucial for Tool Adjusters. Candidates should highlight their ability to work precisely and pay attention to small details. They should provide examples of their meticulousness and accuracy, particularly in relation to setting up and maintaining equipment.

5. Showcase Communication and Teamwork Skills

Tool Adjusters often work as part of a team and collaborate with other departments. Interviewers will assess candidates’ communication skills and ability to work effectively in a team environment. Candidates should provide examples of how they have successfully communicated with colleagues, resolved conflicts, and contributed to team success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool Adjuster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!