Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wooden Barrel Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

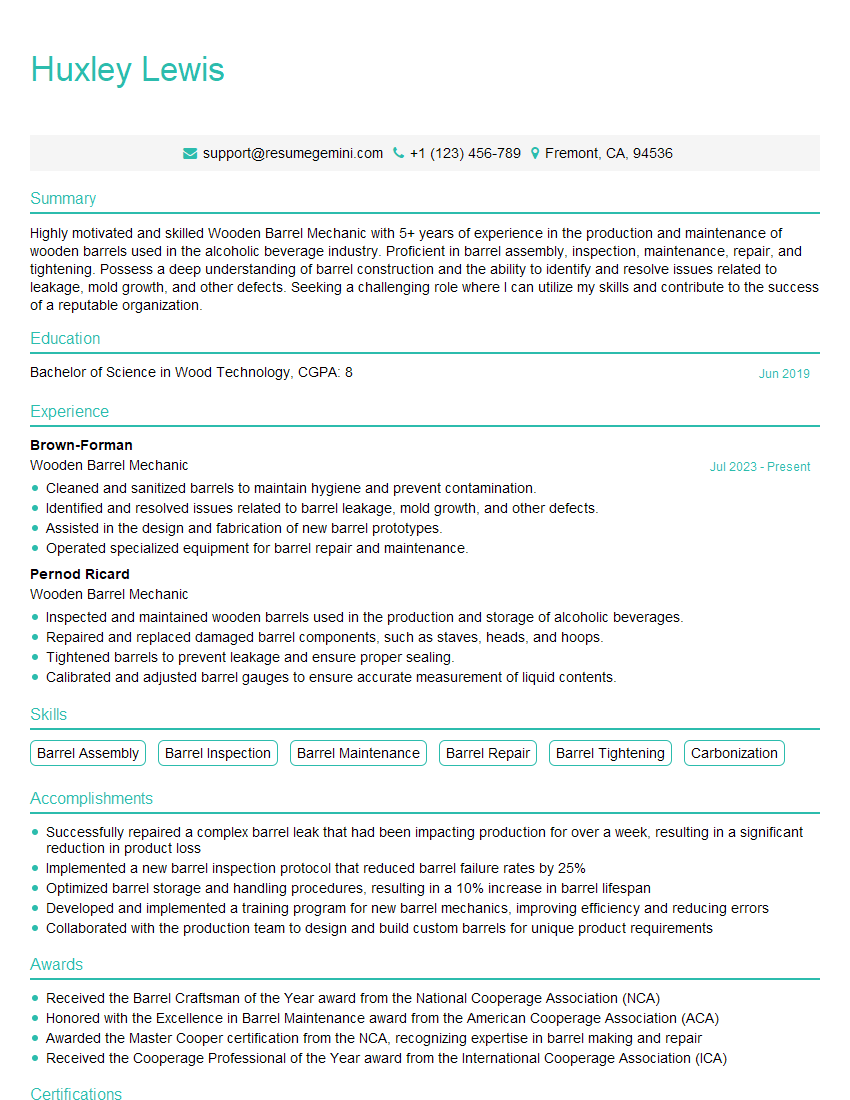

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wooden Barrel Mechanic

1. What are the different types of wooden barrels and what are their uses?

- Tight barrels: Used to store liquids, such as wine, beer, and spirits. They are made from high-quality wood and have a tight fit between the staves.

- Slack barrels: Used to store dry goods, such as flour, grain, and sugar. They are made from less expensive wood and have a looser fit between the staves.

- Half barrels: Used to store liquids or dry goods. They are made from half of a full-size barrel and have a capacity of about 30 gallons.

- Quarter barrels: Used to store liquids or dry goods. They are made from a quarter of a full-size barrel and have a capacity of about 15 gallons.

2. What are the different types of wood used to make wooden barrels and what are their advantages and disadvantages?

of the answer: Oak

- Advantages: Oak is a strong and durable wood that is resistant to rot and decay. It is also a relatively inexpensive wood.

- Disadvantages: Oak is a heavy wood and can be difficult to work with.

Subheading of the answer: Maple

- Advantages: Maple is a strong and durable wood that is resistant to wear and tear. It is also a relatively lightweight wood.

- Disadvantages: Maple is a more expensive wood than oak.

Subheading of the answer: Cherry

- Advantages: Cherry is a beautiful wood with a rich color. It is also a strong and durable wood.

- Disadvantages: Cherry is a more expensive wood than oak and maple.

3. What are the steps involved in making a wooden barrel?

- Select the wood and cut the staves.

- Shape the staves and fit them together.

- Insert the hoops and tighten them.

- Sand the barrel and finish it.

4. What are the different types of hoops used to make wooden barrels and what are their advantages and disadvantages?

- Steel hoops: Steel hoops are the most common type of hoop used to make wooden barrels. They are strong and durable, and they can be easily tightened and loosened.

- Wooden hoops: Wooden hoops are made from wood and are used to make traditional wooden barrels. They are less strong and durable than steel hoops, but they give the barrel a more rustic look.

- Plastic hoops: Plastic hoops are made from plastic and are used to make lightweight wooden barrels. They are not as strong and durable as steel hoops, but they are less expensive and easier to work with.

5. What are the different types of finishes that can be applied to wooden barrels and what are their advantages and disadvantages?

- Lacquer: Lacquer is a clear finish that is applied to wooden barrels to protect them from moisture and wear. It is a durable finish, but it can be difficult to apply.

- Polyurethane: Polyurethane is a clear finish that is applied to wooden barrels to protect them from moisture and wear. It is a more durable finish than lacquer, but it can be more expensive.

- Oil: Oil is a natural finish that is applied to wooden barrels to protect them from moisture and wear. It is a less durable finish than lacquer or polyurethane, but it gives the barrel a more natural look.

6. What are the different types of tools used to make wooden barrels and what are their uses?

- Drawknife: A drawknife is used to shape the staves of a wooden barrel.

- Adze: An adze is used to shape the inside of a wooden barrel.

- Cooper’s hammer: A cooper’s hammer is used to drive the hoops into place on a wooden barrel.

- Bung borer: A bung borer is used to create the hole for the bung.

- Sandpaper: Sandpaper is used to smooth the surface of a wooden barrel.

7. What are the safety precautions that must be taken when working with wooden barrels?

- Wear gloves when handling wooden barrels.

- Wear safety glasses when cutting or sanding wooden barrels.

- Use sharp tools when working with wooden barrels.

- Be aware of the weight of wooden barrels.

- Store wooden barrels in a dry place.

8. What are the different types of problems that can occur with wooden barrels and how can they be fixed?

- Leaks: Leaks can be caused by cracks in the staves, loose hoops, or a damaged bung. They can be fixed by repairing the cracks, tightening the hoops, or replacing the bung.

- Mold: Mold can grow on wooden barrels if they are not properly stored. It can be removed by cleaning the barrel with a bleach solution.

- Rot: Rot can occur if wooden barrels are exposed to moisture for an extended period of time. It can be prevented by storing the barrels in a dry place.

9. What are the different types of regulations that apply to the manufacture and sale of wooden barrels?

- The Food and Drug Administration (FDA) regulates the manufacture and sale of wooden barrels used for food and beverage storage.

- The Environmental Protection Agency (EPA) regulates the disposal of wooden barrels.

- The Occupational Safety and Health Administration (OSHA) regulates the safety of workers who manufacture and sell wooden barrels.

10. What are the latest trends in the wooden barrel industry?

- The use of sustainable wood sources.

- The development of new barrel designs.

- The use of new finishing techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wooden Barrel Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wooden Barrel Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wooden Barrel Mechanics are responsible for the maintenance and repair of wooden barrels used in the wine, whiskey, and other industries. They must have a strong understanding of the construction and materials used in wooden barrels, as well as the ability to use a variety of tools and techniques to repair and maintain them.

1. Inspect and assess barrels

Wooden Barrel Mechanics inspect and assess barrels to identify any damage or defects. They may use a variety of tools, such as gauges, calipers, and magnifying glasses, to examine the barrels for cracks, leaks, or other problems.

- Identify and assess the extent of damage to wooden barrels.

- Determine the cause of damage and recommend appropriate repair techniques.

2. Repair and maintain barrels

Wooden Barrel Mechanics repair and maintain barrels by using a variety of techniques, such as patching, gluing, and replacing damaged staves. They may also use specialized tools and equipment to clean and sterilize barrels.

- Repair leaks in barrels using traditional and modern techniques.

- Replace damaged staves and hoops to restore the structural integrity of barrels.

3. Build new barrels

In some cases, Wooden Barrel Mechanics may also be responsible for building new barrels. They must have a thorough understanding of the construction process and the materials used in wooden barrels.

- Construct new barrels from scratch, ensuring they meet industry standards and specifications.

- Use traditional and modern techniques to create barrels that are both functional and aesthetically pleasing.

4. Maintain a clean and organized workspace

Wooden Barrel Mechanics must maintain a clean and organized workspace to ensure the safety of themselves and others. They must also follow all applicable safety regulations.

- Keep work area clean and organized to minimize the risk of accidents and injuries.

- Adhere to all safety regulations and guidelines to ensure a safe work environment.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Wooden Barrel Mechanic position:

1. Research the company

Before your interview, take some time to research the company you’re applying to. This will help you understand their culture, values, and goals. You can also use this information to tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their history, products or services, and mission statement.

- Read articles and news stories about the company to get a sense of their current projects and initiatives.

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare a short, concise answer to the question “Tell me about yourself” that highlights your skills and experience.

- Practice answering the question “Why are you interested in this position?” by explaining how your skills and interests align with the job requirements.

3. Be prepared to talk about your experience

The interviewer will likely ask you about your experience as a Wooden Barrel Mechanic. Be prepared to discuss your skills and experience in detail, and be sure to highlight any relevant projects or accomplishments.

- Highlight your experience in inspecting, repairing, and maintaining wooden barrels.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

4. Be enthusiastic and professional

First impressions matter, so it’s important to be enthusiastic and professional throughout the interview. Dress appropriately, arrive on time, and be respectful of the interviewer’s time.

- Dress professionally and arrive on time for your interview.

- Be polite and respectful to the interviewer and answer their questions honestly and thoroughly.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wooden Barrel Mechanic, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wooden Barrel Mechanic positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.