Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Alumina Plant Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

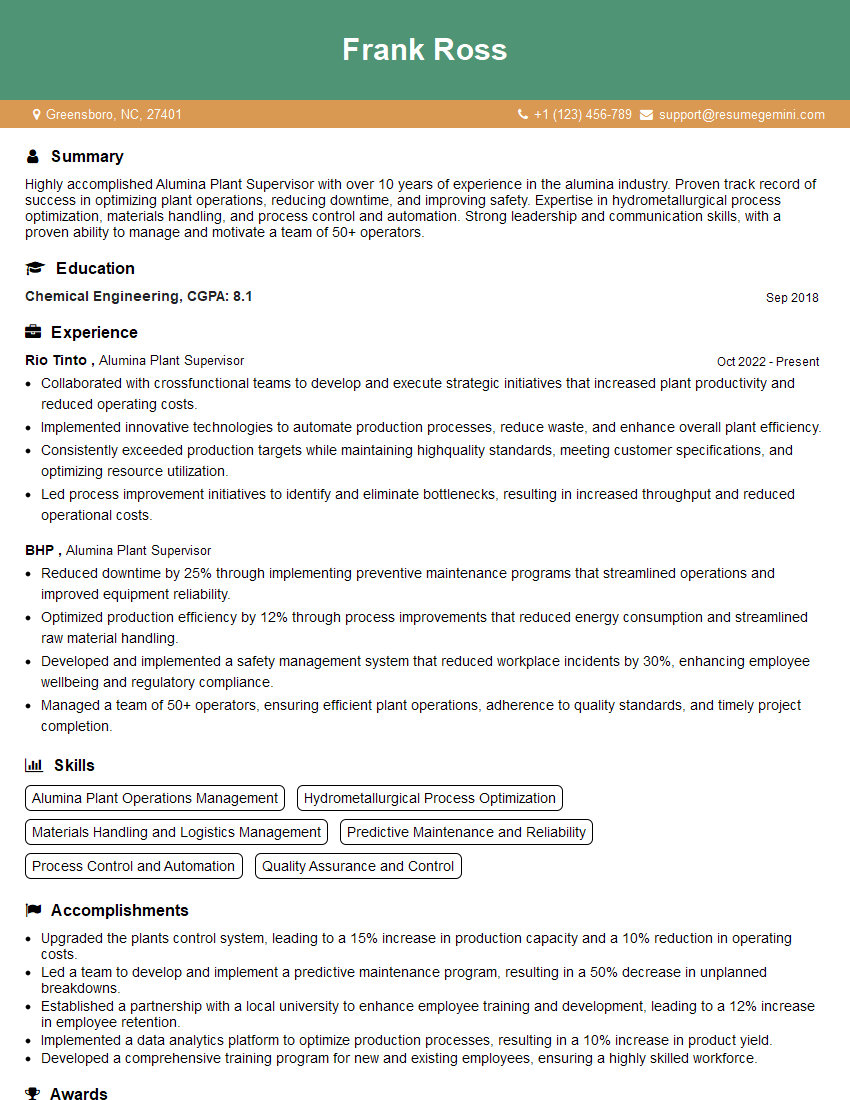

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Alumina Plant Supervisor

1. What are the critical process parameters involved in the alumina production process?

The critical process parameters involved in the alumina production process include:

- Feedstock quality and preparation

- Digestion temperature and pressure

- Precipitation conditions (temperature, pH, and seed addition)

- Filtration and washing efficiency

- Calcination temperature and duration

2. What are the different types of digestion processes used in the alumina industry?

Bayer Process

- High pressure and temperature to dissolve aluminium oxides from bauxite ore

- Most common process globally

Alcoa Process

- High temperature and atmospheric pressure

- Uses a mixture of sodium hydroxide and sodium carbonate

Modified Bayer Process

- Combination of Bayer and Alcoa processes

- Uses lower temperatures and pressures than Bayer process

3. What are the primary impurities found in alumina and how are they removed?

The primary impurities found in alumina include:

- Silica – Removed through digestion and precipitation

- Iron – Removed through digestion and magnetic separation

- Titanium – Removed through digestion and precipitation

- Sodium – Removed through washing and ion exchange

4. What is the Bayer liquor and what are its key characteristics?

Bayer liquor is a sodium hydroxide solution used in the Bayer process for digesting bauxite ore and precipitating alumina.

- High concentration of sodium hydroxide (20-25%)

- High temperature (140-170°C)

- High pressure (5-8 atm)

5. What are the different types of precipitation methods used in the alumina industry?

Controlled Precipitation

- Precisely controlling temperature, pH, and seed addition to obtain desired crystal size and purity

Flash Precipitation

- Rapid cooling of supersaturated Bayer liquor to form fine, uniform crystals

Hydrolysis Precipitation

- Addition of carbon dioxide to Bayer liquor to form aluminium hydroxide, which is then calcined to produce alumina

6. What are the major challenges faced in the operation of an alumina plant?

- Maintaining process stability and efficiency

- Minimizing impurity levels

- Optimizing energy consumption

- Managing environmental impacts

- Ensuring safety and reliability

7. What strategies can be employed to reduce energy consumption in an alumina plant?

- Improving digestion efficiency

- Optimizing calcination process

- Utilizing waste heat recovery systems

- Implementing energy-efficient technologies

- Training and empowering operators for energy conservation

8. What measures can be taken to minimize environmental impacts from an alumina plant?

- Proper waste management and disposal

- Controlling emissions and effluents

- Implementing water conservation measures

- Minimizing land disturbance

- Engaging in community outreach and environmental stewardship programs

9. How do you ensure the safety and reliability of an alumina plant?

- Establishing and implementing comprehensive safety protocols

- Conducting regular risk assessments and inspections

- Providing proper training and certification to operators

- Maintaining equipment and infrastructure in optimal condition

- Developing and implementing emergency response plans

10. What are the key performance indicators (KPIs) for an alumina plant?

- Production output and quality

- Energy consumption

- Impurity levels

- Environmental performance

- Safety record

- Overall equipment effectiveness (OEE)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Alumina Plant Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Alumina Plant Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Alumina Plant Supervisor is a crucial role responsible for overseeing the safe, efficient, and productive operations of an alumina production plant. Key responsibilities include:

1. Production Management

Supervise production processes, including equipment maintenance, raw material handling, and product quality control.

- Monitor production schedules and ensure timely completion of orders

- Optimize production processes to maximize efficiency and minimize waste

2. Quality Control

Ensure the production of high-quality alumina compliant with industry standards and customer specifications.

- Establish and implement quality control procedures

- Oversee product testing and analysis to maintain product quality

3. Environmental Management

Comply with environmental regulations and minimize the plant’s environmental impact.

- Develop and implement environmental management systems

- Monitor emissions and waste disposal to ensure compliance with regulations

4. Health and Safety

Prioritize the health and safety of employees and ensure adherence to safety protocols.

- Establish and enforce safety policies and procedures

- Conduct safety inspections and training to prevent accidents

5. Team Management

Lead and motivate a team of operators, technicians, and engineers.

- Provide guidance, training, and support to team members

- Foster a positive and collaborative work environment

Interview Tips

To ace your interview for an Alumina Plant Supervisor position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, products, and industry trends. This demonstrates your interest in the role and the company.

2. Prepare for Technical Questions

Review your knowledge of alumina production processes, quality control, environmental regulations, and safety protocols. Be ready to discuss your technical expertise.

3. Highlight Your Management Skills

Emphasize your experience in leading and motivating teams, setting clear goals, and fostering a collaborative work environment.

4. Quantify Your Accomplishments

When discussing your previous experiences, provide specific examples and quantify your accomplishments using metrics whenever possible.

5. Showcase Your Safety Focus

Highlight your commitment to safety and your experience in implementing and enforcing safety protocols in a production environment.

6. Be Enthusiastic and Professional

Convey your enthusiasm for the role and demonstrate your professionalism throughout the interview. Be respectful of the interviewer’s time and follow up promptly after the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Alumina Plant Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!