Are you gearing up for an interview for a Beet End Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Beet End Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

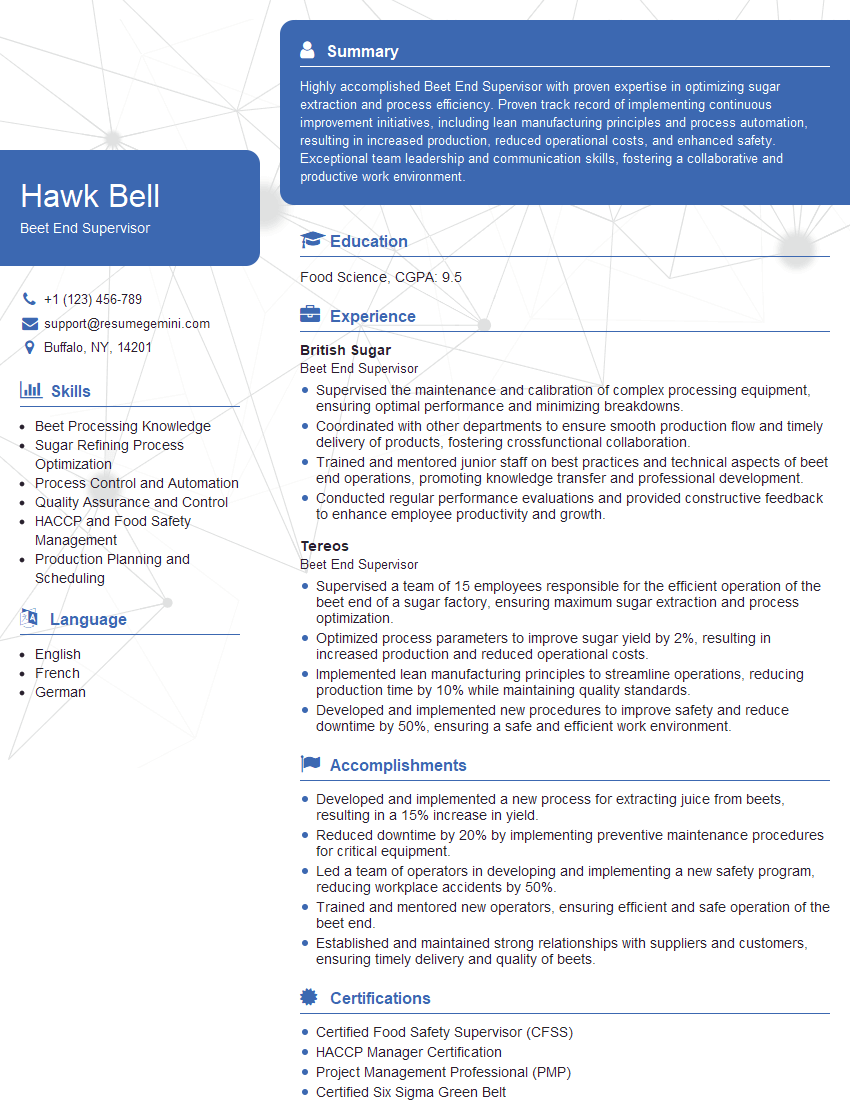

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Beet End Supervisor

1. What is the role of a Beet End Supervisor in a sugar factory?

As a Beet End Supervisor, my responsibilities in a sugar factory would include:

- Overseeing the unloading, weighing, and sampling of incoming beets.

- Monitoring and controlling the beet washing, slicing, and extraction processes.

- Ensuring the efficient operation and maintenance of beet end machinery.

- Collaborating with other departments to optimize beet utilization and sugar production.

- Implementing and maintaining quality control measures to ensure the production of high-quality sugar.

2. Describe the importance of maintaining optimal pH levels during beet extraction.

Impact on Sugar Yield

- Maintaining an optimal pH range between 10-11.5 is crucial for maximizing sugar yield.

- High pH levels lead to increased sugar degradation, while low pH levels reduce sugar solubility.

Prevention of Equipment Corrosion

- pH levels also affect the corrosion of equipment used in the extraction process.

- Extreme pH conditions can damage pipelines, tanks, and other components, leading to costly repairs and downtime.

3. How do you ensure that the beet pulp is properly dewatered before being sent to the pulp dryer?

To ensure proper dewatering of beet pulp before sending it to the pulp dryer, I implement the following measures:

- Utilizing efficient pulp presses to remove as much water as possible.

- Monitoring the moisture content of the pulp to ensure it meets the specifications for the pulp dryer.

- Regularly cleaning and maintaining the pulp presses to prevent blockages and ensure optimal performance.

- Implementing a system to recycle the press water for maximum water recovery.

4. What is the purpose of the thickener in the beet end process?

The thickener in the beet end process serves the following purpose:

- Separating solids (beet pulp) from the juice extracted from the beets.

- Increasing the concentration of solids in the pulp before sending it to the pulp dryer.

- Reducing the volume of the juice stream for more efficient processing in subsequent stages.

- Recovering valuable nutrients and proteins from the juice for further use.

5. How do you handle process upsets or deviations that occur in the beet end of the factory?

In the event of process upsets or deviations in the beet end, I follow a systematic approach:

- Quickly identifying the source of the upset using available instrumentation and observation.

- Taking immediate corrective action to stabilize the process and prevent further disruptions.

- Investigating the root cause of the upset to prevent future occurrences.

- Communicating with other departments and management to ensure a coordinated response.

- Documenting the event and implementing corrective measures to enhance process stability.

6. What is the importance of adhering to HACCP principles in the beet end operation?

Adhering to HACCP principles in the beet end operation is crucial for ensuring the safety and quality of the sugar produced:

- Identifying and controlling potential hazards that could contaminate the sugar.

- Establishing critical control points (CCPs) where hazards can be prevented, eliminated, or reduced to acceptable levels.

- Monitoring and verifying CCPs to ensure they are operating effectively.

- Taking corrective actions when deviations occur to prevent hazards from impacting the sugar.

- Maintaining documentation and records to demonstrate compliance with HACCP principles.

7. How do you manage the energy consumption of the beet end operation?

Managing energy consumption in the beet end operation is essential for cost optimization and sustainability:

- Monitoring energy usage through metering and data analysis.

- Identifying areas of high energy consumption and implementing energy-efficient practices.

- Optimizing equipment performance and maintenance schedules to reduce energy waste.

- Utilizing energy-efficient motors, pumps, and other equipment.

- Educating staff on energy conservation measures and encouraging their involvement.

8. What is the role of instrumentation and automation in the beet end process?

Instrumentation and automation play a vital role in the beet end process:

- Monitoring and controlling process parameters such as temperature, pH, and flow rates.

- Automating tasks such as valve control, pump operation, and data logging.

- Improving process stability and efficiency by reducing human error.

- Providing real-time data for process optimization and troubleshooting.

- Ensuring compliance with regulatory requirements and maintaining product quality.

9. How do you ensure the safety of personnel working in the beet end area?

Ensuring the safety of personnel in the beet end area is paramount:

- Enforcing the use of personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Implementing lockout/tagout procedures for equipment maintenance.

- Providing regular safety training to all personnel on potential hazards and safe work practices.

- Conducting regular safety inspections to identify and mitigate potential risks.

- Establishing emergency response plans and ensuring personnel are aware of evacuation procedures.

10. What are the key performance indicators (KPIs) that you monitor in the beet end operation?

I track the following KPIs to assess the performance of the beet end operation:

- Beet throughput and processing efficiency.

- Sugar extraction rate and yield.

- Pulp dewatering efficiency.

- Energy consumption.

- Equipment uptime and maintenance costs.

- Compliance with quality standards and regulatory requirements.

- Safety performance and incident rates.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Beet End Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Beet End Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Beet End Supervisor is responsible for overseeing and managing the production process of beet pulp and molasses at a sugar factory, ensuring the smooth and efficient operation of the beet end.

1. Production Management

Directs and coordinates the overall production process, including beet receiving, washing, slicing, maceration, and extraction.

2. Equipment Maintenance

Oversees the maintenance and repair of all production equipment, including conveyors, slicers, macerators, and extractors. Regularly inspects equipment to identify potential issues and implements preventive maintenance strategies.

3. Process Optimization

Monitors process data and analyzes key performance indicators (KPIs) to identify areas for improvement. Implements process modifications and adjustments to optimize production efficiency and maximize sugar yield.

4. Quality Control

Ensures the production of high-quality beet pulp and molasses by implementing and maintaining strict quality control standards. Monitors product quality throughout the process and takes corrective actions to maintain specifications.

5. Team Management

Leads and motivates a team of operators, technicians, and support staff. Assigns tasks, provides training, and establishes clear performance expectations.

6. Plant Safety

Ensures the health and safety of employees by adhering to established safety protocols. Monitors working conditions, conducts safety inspections, and implements risk assessment procedures.

Interview Tips

To ace an interview for the Beet End Supervisor position, candidates should:

1. Research the Company and Industry

Review the company’s website, industry publications, and news articles to gain insights into their operations, market position, and the specific role you are applying for.

2. Highlight Relevant Experience

Emphasize your previous experience in beet sugar production or other relevant industries. Quantify your accomplishments using specific metrics to demonstrate your impact on production efficiency, quality, or cost savings.

3. Showcase Problem-Solving Abilities

Describe experiences where you identified and resolved production issues or process bottlenecks. Explain your analytical approach, problem-solving techniques, and the positive outcomes you achieved.

4. Demonstrate Leadership Skills

Highlight your ability to lead and motivate teams. Provide examples of how you have successfully managed and developed staff, fostered teamwork, and created a positive work environment.

5. Prepare Industry-Specific Knowledge

Familiarize yourself with key industry terms, processes, and technological advancements. Be ready to discuss your understanding of beet handling, extraction methods, and quality control parameters.

Next Step:

Now that you’re armed with the knowledge of Beet End Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Beet End Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini