Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metallurgical Engineering Teacher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

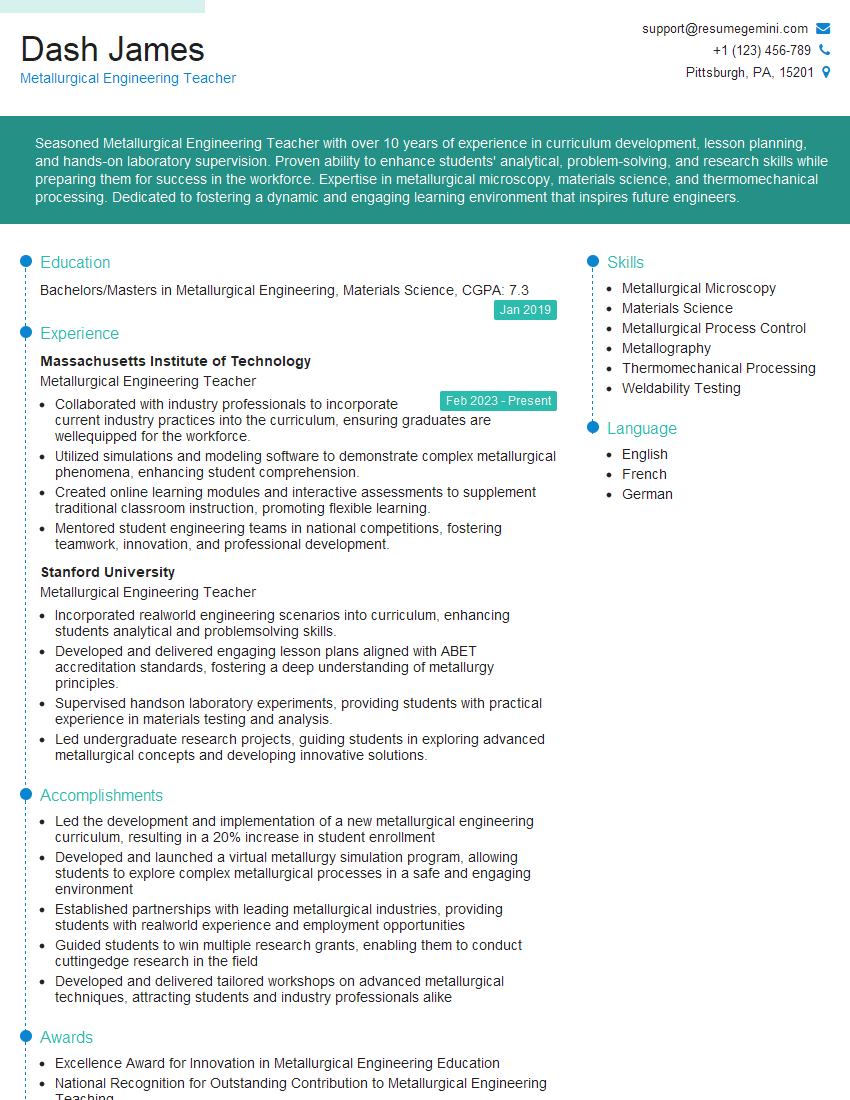

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metallurgical Engineering Teacher

1. Describe the steps involved in the heat treatment of steel?

The heat treatment of steel involves a series of controlled heating and cooling processes that alter the material’s properties:

- Annealing: Heating the steel to a high temperature, holding it for a period of time, and then cooling it slowly to soften it and relieve internal stresses.

- Normalizing: Heating the steel to a high temperature and then cooling it in air to refine the grain structure and improve strength and toughness.

- Hardening: Heating the steel to a critical temperature and then rapidly cooling it to increase hardness and wear resistance.

- Tempering: Heating the hardened steel to a lower temperature and then cooling it to reduce brittleness and improve toughness.

2. Explain the different types of phase transformations that occur in steels during heat treatment?

Austenite to Martensite Transformation

- Occurs during rapid cooling of austenite (FCC) to form martensite (BCT).

- Martensite is a very hard and brittle phase.

Austenite to Ferrite Transformation

- Occurs during slow cooling of austenite to form ferrite (BCC).

- Ferrite is a soft and ductile phase.

Austenite to Pearlite Transformation

- Occurs during intermediate cooling of austenite to form pearlite (a mixture of ferrite and cementite).

- Pearlite has a lamellar structure and is harder than ferrite but softer than martensite.

3. Discuss the factors that influence the mechanical properties of steel?

The mechanical properties of steel are influenced by various factors:

- Composition: The presence and amount of alloying elements, such as carbon, manganese, and chromium, can significantly alter the properties.

- Heat treatment: The specific heat treatment processes applied can modify the microstructure and thus the mechanical properties.

- Microstructure: The size, shape, and distribution of grains, phases, and defects within the steel can affect its strength, toughness, and other properties.

- Processing history: The methods used to produce the steel, such as casting, rolling, or forging, can influence its mechanical properties.

4. Describe the different types of steels and their applications?

There are various types of steels, each tailored for specific applications:

- Carbon steels: Contain varying amounts of carbon and are classified based on their carbon content. They are widely used in structural applications, automotive parts, and tools.

- Alloy steels: Contain additional alloying elements, such as chromium, nickel, or molybdenum, to enhance specific properties like strength, corrosion resistance, or wear resistance.

- Tool steels: Specially designed for cutting and forming tools, with high hardness and wear resistance due to the presence of alloying elements like tungsten or vanadium.

- Stainless steels: Contain a minimum of 10.5% chromium, providing excellent corrosion resistance and are used in food processing, chemical equipment, and medical applications.

5. Explain the principles of solidification in metals?

Solidification in metals involves the transition from a liquid to a solid state:

- Nucleation: Formation of solid crystal nuclei within the liquid metal.

- Growth: Atoms from the liquid metal diffuse towards the nuclei and attach to their crystal structure, causing them to grow.

- Phase transformation: As the temperature decreases, more nuclei form and grow, leading to the transformation of the entire liquid into a solid.

6. Describe the different strengthening mechanisms in metals?

Metals can be strengthened through various mechanisms:

- Grain refinement: Reducing the grain size increases the number of grain boundaries, which act as barriers to dislocation movement.

- Solid solution strengthening: Adding alloying elements to the metal creates a solid solution that hinders dislocation movement.

- Precipitation strengthening: Introducing a second phase that precipitates out of the matrix and acts as a barrier to dislocations.

- Work hardening: Plastic deformation introduces dislocations into the metal, which interact with each other and impede further deformation.

7. Explain the concept of the phase diagram for a binary alloy system?

A binary alloy system phase diagram shows the relationship between the composition, temperature, and phases present in an alloy:

- Solidus line: Temperature at which the last bit of solid forms during cooling.

- Liquidus line: Temperature at which the last bit of liquid solidifies during heating.

- Phase boundaries: Lines separating different phase regions on the diagram.

- Phase regions: Areas on the diagram where a specific phase (e.g., liquid, solid) is stable.

8. Discuss the different types of defects that can occur in metals?

Metal defects can be classified into various types:

- Point defects: Vacancies, interstitials, and substitutional atoms that disrupt the crystal structure.

- Line defects (dislocations): Disruptions in the crystal lattice that cause a localized distortion.

- Planar defects: Boundaries between different crystal grains or phases in the metal.

- Volume defects: Inclusions, pores, and cracks that occupy a volume within the metal.

9. Describe the principles of X-ray diffraction for analyzing crystal structure?

X-ray diffraction is a technique used to determine the crystal structure of materials:

- Bragg’s law: Relates the wavelength of X-rays, the angle of diffraction, and the spacing between crystal planes.

- Diffraction pattern: A pattern of spots or rings on a detector created by the constructive interference of X-rays scattered by the crystal.

- Unit cell: The smallest repeating unit of a crystal structure, which can be determined from the diffraction pattern.

10. Explain the different methods of metal forming?

Metal forming involves shaping metals through various processes:

- Rolling: Passing metal through rollers to reduce thickness.

- Extrusion: Forcing metal through a die to create a desired shape.

- Forging: Shaping metal by hammering or pressing.

- Casting: Pouring molten metal into a mold.

- Powder metallurgy: Compacting and sintering metal powders to create a desired shape.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metallurgical Engineering Teacher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metallurgical Engineering Teacher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metallurgical Engineering Teachers are responsible for instructing students in the principles and applications of metallurgical engineering. They typically work in university or college settings, and their responsibilities may include developing and delivering lectures, leading laboratory and studio sessions, and conducting research.

1. Develop and Deliver Lectures

Teachers in this role are expected to develop and deliver lectures that cover the fundamental principles of metallurgical engineering. This may include topics such as the properties of metals, the principles of metalworking, and the design and analysis of metallurgical processes.

- Create and deliver engaging lectures that effectively convey complex technical concepts.

- Use a variety of teaching methods, such as presentations, simulations, and hands-on activities, to cater to different learning styles.

2. Lead Laboratory and Studio Sessions

Teachers may also be responsible for leading laboratory and studio sessions, where students apply the principles learned in lectures to practical projects. This may involve overseeing students as they conduct experiments, operate equipment, and analyze data.

- Design and lead lab experiments and studio projects that reinforce theoretical concepts.

- Provide hands-on guidance and support to students, ensuring their safety and progress.

3. Conduct Research

In addition to teaching, Metallurgical Engineering Teachers may also be involved in research activities. This may involve conducting experiments, developing new materials or processes, or collaborating with industry partners.

- Conduct fundamental and applied research to advance the field of metallurgical engineering.

- Publish research findings in peer-reviewed journals and present at conferences.

4. Advise Students

Teachers in this role may also provide academic and career advice to students. This may involve helping students choose courses, develop research projects, and prepare for careers in metallurgical engineering.

- Provide academic guidance and mentorship to students, supporting their intellectual and professional development.

- Assist students with career exploration and preparation, connecting them with industry partners and alumni.

Interview Tips

Preparing for an interview for a Metallurgical Engineering Teacher position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace the interview:

1. Research the School and Position

Before the interview, take the time to research the school and the specific position you are applying for. This will help you understand the school’s mission, values, and curriculum, as well as the specific responsibilities and expectations of the role.

- Visit the school’s website to learn about its history, programs, and faculty.

- Review the course descriptions for the metallurgical engineering program to understand the curriculum and student learning outcomes.

2. Prepare for Common Interview Questions

There are a few common interview questions that you are likely to encounter in an interview for a Metallurgical Engineering Teacher position. These questions may include:

- Tell me about your experience teaching metallurgical engineering.

- What are your strengths and weaknesses as a teacher?

- How do you stay up-to-date on the latest developments in metallurgical engineering?

- What are your research interests?

- Why are you interested in teaching at this school?

It is important to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

3. Bring a Portfolio of Your Work

If you have any examples of your teaching materials, research publications, or other relevant work, consider bringing a portfolio to the interview. This will give the interviewers a tangible example of your skills and experience.

- Include samples of lesson plans, lecture notes, or lab exercises that you have developed.

- Provide copies of any research papers or publications that you have authored or co-authored.

4. Dress Professionally and Arrive on Time

First impressions matter, so be sure to dress professionally for the interview. Also, arrive on time to show that you are respectful of the interviewers’ time.

- Choose attire that is appropriate for an academic setting, such as a suit or business casual.

- Plan your route to the interview location in advance to avoid any delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metallurgical Engineering Teacher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.