Are you gearing up for a career in Continuous Weld Pipe Mill Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Continuous Weld Pipe Mill Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

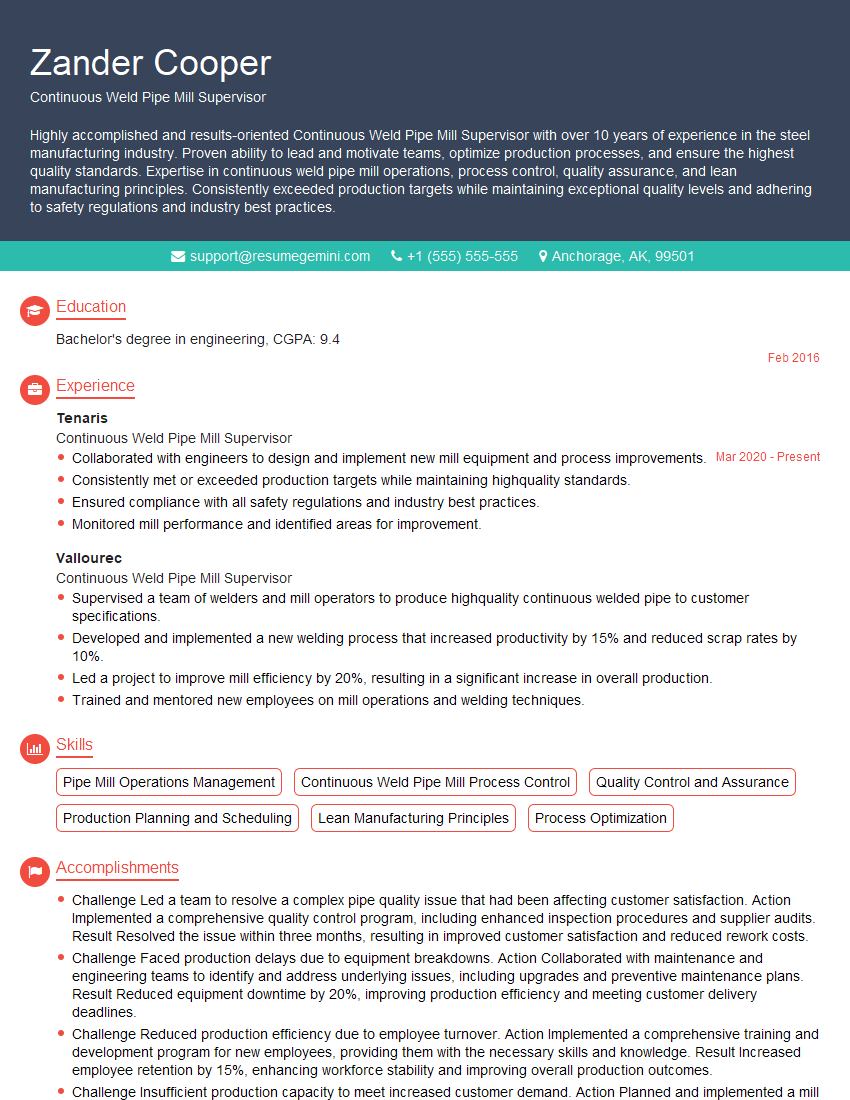

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Continuous Weld Pipe Mill Supervisor

1. Describe the steps involved in the continuous weld pipe mill process.

The steps involved in the continuous weld pipe mill process are as follows:

- Uncoiling the steel strip from the coil

- Leveling the steel strip to remove any imperfections

- Edge trimming the steel strip to remove any excess material

- Forming the steel strip into a cylindrical shape

- Joining the edges of the steel strip together using a welding process

- Cooling the pipe to a desired temperature

- Coating the pipe to protect it from corrosion

- Cutting the pipe to the desired length

- Inspecting the pipe to ensure it meets the required quality standards

2. What are the key quality control parameters in the continuous weld pipe mill process?

Steel strip quality

- Tensile strength

- Yield strength

- Elongation

- Thickness

- Width

Welding parameters

- Welding speed

- Welding current

- Welding voltage

- Welding torch position

Pipe dimensions

- Outside diameter

- Inside diameter

- Wall thickness

- Length

Pipe properties

- Tensile strength

- Yield strength

- Elongation

- Hardness

- Corrosion resistance

3. What are the common defects that can occur in the continuous weld pipe mill process and how can they be prevented?

Laps

- Cause: Misalignment of the steel strip edges during welding

- Prevention: Proper alignment of the steel strip edges

Scabs

- Cause: Inclusions or impurities in the steel strip

- Prevention: Use of high-quality steel strip and proper cleaning of the steel strip before welding

Laminations

- Cause: Defects in the steel strip

- Prevention: Use of high-quality steel strip and proper inspection of the steel strip before welding

Cracks

- Cause: Improper welding parameters

- Prevention: Optimization of welding parameters

4. What are the different welding processes that can be used in the continuous weld pipe mill process?

- Submerged arc welding (SAW)

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

- Plasma arc welding (PAW)

- Laser beam welding (LBW)

5. What are the advantages and disadvantages of using SAW in the continuous weld pipe mill process?

Advantages

- High welding speed

- High weld quality

- Low welding cost

Disadvantages

- Limited visibility of the weld pool

- High heat input

- Large amount of slag generated

6. What are the key factors that affect the productivity of a continuous weld pipe mill?

- Speed of the mill

- Quality of the steel strip

- Efficiency of the welding process

- Availability of the mill

- Skill of the operators

7. What are the safety hazards associated with the continuous weld pipe mill process and how can they be minimized?

Electrical hazards

- Cause: Contact with live electrical components

- Prevention: Use of proper electrical insulation and grounding

Mechanical hazards

- Cause: Contact with moving machinery

- Prevention: Use of machine guards and proper training of operators

Fire hazards

- Cause: Welding sparks and hot metal

- Prevention: Use of fire extinguishers and proper ventilation

Chemical hazards

- Cause: Exposure to welding fumes and gases

- Prevention: Use of proper ventilation and respiratory protection

8. What are the environmental impacts of the continuous weld pipe mill process and how can they be minimized?

Air pollution

- Cause: Welding fumes and gases

- Prevention: Use of proper ventilation and emission control systems

Water pollution

- Cause: Discharge of wastewater from the cooling process

- Prevention: Use of proper wastewater treatment systems

Solid waste

- Cause: Scrap metal and welding consumables

- Prevention: Use of proper recycling and waste management practices

9. What are the latest trends in the continuous weld pipe mill industry?

- Increased use of high-strength steel

- Development of new welding technologies

- Automation of the production process

- Implementation of lean manufacturing principles

10. What are the challenges facing the continuous weld pipe mill industry?

- Increasing competition from other pipe manufacturing technologies

- Fluctuating steel prices

- Environmental regulations

- Shortage of skilled workers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Continuous Weld Pipe Mill Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Continuous Weld Pipe Mill Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Continuous Weld Pipe Mill Supervisor is responsible for overseeing the safe and efficient operation of the pipe mill. This includes managing a team of operators, ensuring that the mill is running at peak efficiency, and producing high-quality pipe. This may include the following key job responsibilities.

1. Manage a team of operators

This includes hiring, training, and supervising a team of operators. The supervisor must also ensure that the operators are following safety procedures and working efficiently.

- Hire, train, and supervise a team of operators

- Ensure that the operators are following safety procedures

- Motivate and lead the team to achieve production goals

2. Ensure that the mill is running at peak efficiency

This includes monitoring the mill’s performance, identifying areas for improvement, and making necessary adjustments. The supervisor must have a strong understanding of the operation of the pipe mill and the ability to make sound decisions.

- Monitor the mill’s performance

- Identify areas for improvement

- Make necessary adjustments

- Ensure that the mill is operating at peak efficiency

3. Produce high-quality pipe

This includes inspecting the pipe for defects, ensuring that it meets customer specifications, and taking corrective action when necessary. The supervisor must have a strong quality assurance program in place.

- Inspect the pipe for defects

- Ensure that the pipe meets customer specifications

- Take corrective action when necessary

- Maintain a strong quality assurance program

4. Other responsibilities

In addition to the above, the Continuous Weld Pipe Mill Supervisor may also be responsible for the following:

- Budgeting and forecasting

- Purchasing and inventory management

- Customer service

- Safety and environmental compliance

Interview Tips

In order to ace the interview for a Continuous Weld Pipe Mill Supervisor position, take some time to prepare so you can perform your best during the interview. Here are some tips to help you prepare:

1. Research the company and the position

Before the interview, take time to research the company and the position you are applying for. This will help you understand the company’s culture, the industry, and the specific job duties you will be responsible for.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work in the industry

- Prepare questions to ask the interviewer

2. Practice your answers to common interview questions

There are many common interview questions that you may be asked. Take some time to practice your answers to these questions so that you can deliver confident and well-thought-out responses during the interview.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with continuous weld pipe mills?

- How do you motivate and lead a team?

3. Dress professionally and arrive on time

First impressions matter. Dress professionally for the interview and arrive on time. This will show the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Arrive for the interview on time

4. Be enthusiastic and positive

The interviewer wants to know that you are excited about the position and that you are confident in your abilities. Be enthusiastic and positive during the interview. This will make a good impression on the interviewer and will help you stand out from other candidates.

- Smile and make eye contact

- Be confident in your answers

- Show your passion for the industry

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Continuous Weld Pipe Mill Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Continuous Weld Pipe Mill Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.