Are you gearing up for a career in Cutting Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cutting Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

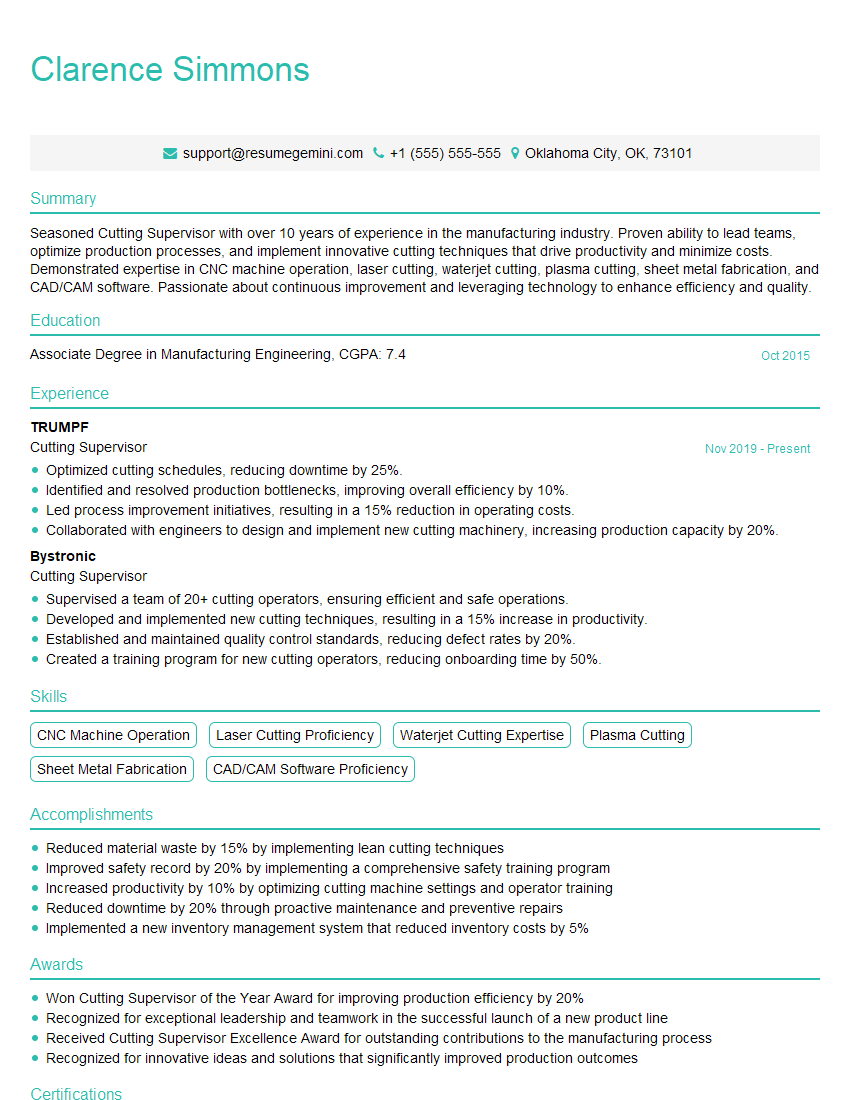

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutting Supervisor

1. How do you ensure the accuracy and efficiency of cutting operations?

To ensure accuracy and efficiency in cutting operations, I employ various strategies:

- Meticulous planning: I thoroughly review designs, assess material properties, and establish precise cutting parameters before initiating any cuts.

- Advanced cutting technologies: I utilize state-of-the-art cutting equipment, such as CNC (Computer Numerical Control) machines, to achieve precise and consistent cuts.

- Rigorous quality control: I implement comprehensive quality control measures, including regular equipment calibration, material inspections, and post-cut verification, to guarantee the accuracy of every cut.

- Operator training and development: I invest in training and development programs for cutting operators to enhance their skills and knowledge, ensuring they possess the necessary expertise to operate cutting equipment effectively.

2. What techniques do you use to minimize material waste and optimize yield?

Minimizing material waste and optimizing yield are crucial aspects of my approach as a Cutting Supervisor:

- Efficient nesting: I utilize advanced nesting software to optimize material placement on cutting platforms, minimizing waste and maximizing yield.

- Remnant management: I establish a comprehensive system for managing cutting remnants, ensuring their efficient utilization in future operations or for secondary products.

- Scrap analysis: I conduct regular scrap analysis to identify areas for improvement in cutting processes, reducing waste and enhancing overall efficiency.

- Collaboration with design team: I work closely with the design team to optimize product designs, considering factors such as material utilization and cutting efficiency, to minimize waste from the outset.

3. How do you manage cutting schedules and prioritize production orders?

Effective production scheduling is essential for smooth and efficient cutting operations:

- Advanced scheduling software: I leverage scheduling software to create and manage production schedules, considering factors such as material availability, machine capacity, and customer deadlines.

- Prioritization strategies: I establish clear and objective prioritization criteria, such as order urgency, customer importance, and production capacity, to determine the sequence of production orders.

- Communication and coordination: I maintain open communication with production teams, sales representatives, and customers to ensure timely updates and adjustments to the production schedule as needed.

- Contingency planning: I develop contingency plans to address unexpected events, such as equipment breakdowns or material delays, to minimize disruptions to production schedules.

4. What quality control measures do you implement to ensure the quality of cut products?

Maintaining high product quality is paramount in my role as a Cutting Supervisor:

- Visual inspection: I implement thorough visual inspection procedures at various stages of the cutting process to identify any defects or inconsistencies.

- Dimensional verification: I utilize precision measuring tools and gauges to verify the dimensions and specifications of cut products, ensuring they meet established tolerances.

- Material testing: I conduct material testing, such as tensile strength and hardness tests, to validate the quality of cut materials and ensure their suitability for intended applications.

- Feedback and continuous improvement: I encourage feedback from customers and quality control teams to identify areas for improvement in cutting processes and product quality.

5. How do you ensure the safety of cutting operations and maintain a safe work environment?

Safety is an utmost priority in cutting operations, and I take the following measures to ensure a safe work environment:

- Comprehensive safety training: I provide comprehensive safety training to all cutting operators, covering topics such as proper machine operation, hazard identification, and emergency response procedures.

- Regular safety inspections: I conduct regular safety inspections of cutting equipment, work areas, and personal protective equipment (PPE) to identify and eliminate potential hazards.

- Safety protocols and guidelines: I establish clear safety protocols and guidelines for cutting operations, including machine operation procedures, material handling practices, and emergency response plans.

- Enforcement of safety regulations: I strictly enforce safety regulations and hold cutting operators accountable for adhering to established safety standards.

6. How do you monitor cutting equipment performance and implement maintenance strategies?

Effective equipment monitoring and maintenance are crucial for optimizing cutting operations:

- Regular equipment inspections: I establish a schedule for regular equipment inspections to identify potential issues and address them proactively.

- Performance monitoring: I monitor key performance indicators (KPIs) such as machine utilization, cutting speed, and accuracy to assess equipment performance and identify areas for improvement.

- Predictive maintenance: I employ predictive maintenance techniques, such as vibration analysis and temperature monitoring, to anticipate potential equipment failures and schedule maintenance accordingly.

- Collaboration with maintenance team: I work closely with the maintenance team to ensure timely and effective repairs, minimizing downtime and maintaining equipment efficiency.

7. How do you manage a team of cutting operators and motivate them to achieve high levels of performance?

Team management and motivation are essential for a successful cutting operation:

- Clear communication: I establish open and transparent communication channels to ensure that cutting operators are well-informed about their tasks, goals, and expectations.

- Performance feedback: I provide regular performance feedback to cutting operators, recognizing their achievements and offering guidance for improvement.

- Training and development: I invest in training and development opportunities for cutting operators to enhance their skills and knowledge, empowering them to perform at their best.

- Recognition and rewards: I implement recognition and reward programs to acknowledge and celebrate the contributions of cutting operators, fostering a positive and motivated work environment.

8. How do you stay up-to-date with the latest advancements in cutting technologies and best practices?

Continuous professional development is essential in my role:

- Industry conferences and exhibitions: I attend industry conferences and exhibitions to learn about the latest advancements in cutting technologies and best practices.

- Technical journals and publications: I subscribe to technical journals and publications to stay abreast of new cutting techniques, materials, and equipment.

- Online learning platforms: I utilize online learning platforms to access courses and tutorials on cutting-edge technologies and industry trends.

- Collaboration with experts: I connect with experts in the cutting industry to exchange knowledge, best practices, and industry insights.

9. How do you handle unexpected challenges or problems that arise during cutting operations?

Unexpected challenges are an inherent part of cutting operations:

- Problem identification: I quickly identify and assess the nature of the challenge or problem.

- Root cause analysis: I conduct a thorough root cause analysis to determine the underlying factors contributing to the issue.

- Solution development: I brainstorm potential solutions, considering technical constraints, safety implications, and operational feasibility.

- Implementation and evaluation: I implement the most appropriate solution and monitor its effectiveness, making necessary adjustments as needed.

10. What strategies do you employ to optimize cutting processes and improve overall efficiency?

Continuous process optimization is a key focus area for me:

- Process mapping and analysis: I map and analyze cutting processes to identify bottlenecks and areas for improvement.

- Lean manufacturing principles: I implement lean manufacturing principles, such as 5S and Kaizen, to eliminate waste, reduce lead times, and enhance overall efficiency.

- Collaboration with other departments: I collaborate with other departments, such as engineering and quality control, to optimize material specifications, cutting parameters, and inspection procedures.

- Benchmarking and best practices: I benchmark our cutting processes against industry best practices and implement proven techniques to improve efficiency and productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutting Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutting Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cutting Supervisor plays a pivotal role in overseeing the production of high-quality cut materials, ensuring efficient operations, and maintaining safety within the cutting department.

1. Production Management

Supervises and coordinates cutting operations to achieve production targets, adhering to quality standards and deadlines.

- Plans and schedules production, allocates resources, and assigns tasks to operators.

- Monitors progress, identifies bottlenecks, and implements corrective actions to optimize workflow.

2. Quality Control

Ensures compliance with quality specifications by inspecting cut materials, verifying dimensions, and checking for defects.

- Conducts regular quality audits to identify areas for improvement and maintain high standards.

- Provides training and guidance to operators on proper cutting techniques and quality control measures.

3. Safety and Compliance

Maintains a safe working environment by enforcing safety protocols, conducting risk assessments, and providing safety training.

- Complies with all applicable safety regulations and industry standards.

- Conducts regular safety inspections, identifies potential hazards, and implements preventive measures.

4. Team Management

Leads and motivates a team of cutting operators, fostering a positive and productive work environment.

- Provides training, coaching, and performance evaluations to enhance operator skills and productivity.

- Communicates effectively with team members, clearly conveying instructions and addressing concerns.

Interview Tips

To ace an interview for a Cutting Supervisor position, it is crucial to prepare thoroughly and showcase your relevant skills and experience. Here are some effective tips:

1. Research the Company and the Role

Thoroughly research the company’s website, industry reputation, and specific cutting operations to gain insights into their business and the role you are applying for.

- Identify the company’s products, services, and market position.

- Understand the cutting techniques and equipment used in the industry and specific to the company.

2. Highlight Your Experience and Skills

Tailor your resume and cover letter to emphasize your cutting supervision experience, including specific examples of your accomplishments.

- Quantify your results whenever possible, using metrics such as production targets met, quality improvement initiatives implemented, or safety incident reduction.

- Demonstrate your knowledge of cutting techniques, quality control procedures, and safety regulations.

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that showcase your skills and experience.

- “Tell me about your experience in supervising cutting operations.”

- “Describe a time when you successfully implemented quality control measures in a cutting department.”

- “How do you ensure safety in the workplace and comply with industry regulations?”

4. Practice Your Answers

Rehearse your answers to common interview questions out loud to improve your delivery and confidence.

- Seek feedback from a friend, family member, or career counselor.

- Time yourself to ensure concise and well-structured responses.

5. Dress Professionally and Be Punctual

First impressions matter, so dress professionally and arrive at the interview on time.

- Choose attire that is business casual or formal, depending on the company culture.

- Be respectful of the interviewer’s time and schedule.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cutting Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!