Feeling lost in a sea of interview questions? Landed that dream interview for Defluorinated Phosphate Production Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Defluorinated Phosphate Production Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

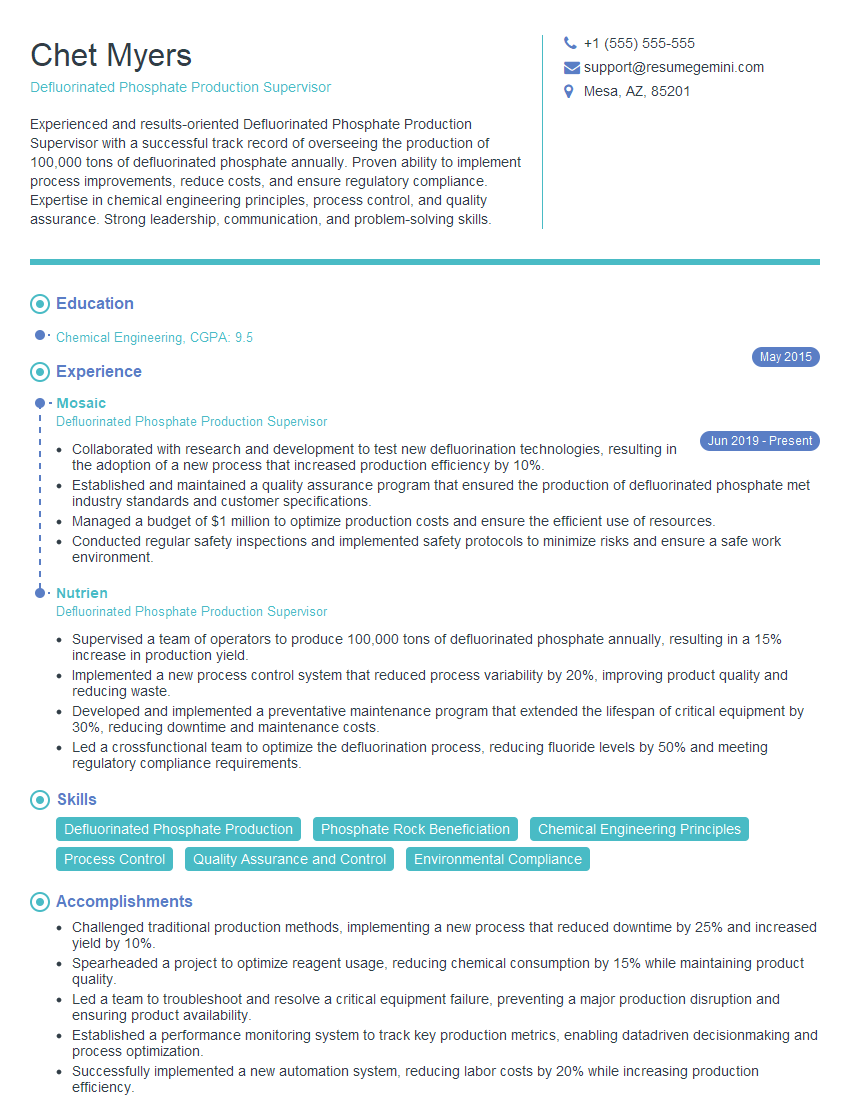

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Defluorinated Phosphate Production Supervisor

1. What are the key responsibilities of a Defluorinated Phosphate Production Supervisor?

The key responsibilities of a Defluorinated Phosphate Production Supervisor include:

- Supervising the production of defluorinated phosphate

- Ensuring that the production process meets all quality standards

- Monitoring the production equipment and making sure that it is running properly

- Troubleshooting any problems that may arise during the production process

- Training and supervising production staff

- Maintaining a safe and clean work environment

- Following all company policies and procedures

2. What are the different types of defluorinated phosphate production processes?

- The two main types of defluorinated phosphate production processes are the wet process and the dry process.

- The wet process involves reacting phosphate rock with sulfuric acid to produce phosphoric acid, which is then defluorinated using a solvent extraction process.

- The dry process involves reacting phosphate rock with a reducing agent, such as carbon, to produce elemental phosphorus, which is then defluorinated using a thermal process.

3. What are the key quality standards for defluorinated phosphate?

- The key quality standards for defluorinated phosphate include:

- Fluoride content

- Phosphorus content

- Moisture content

- Particle size

- pH

4. What are the most common problems that can occur during the production of defluorinated phosphate?

- The most common problems that can occur during the production of defluorinated phosphate include:

- Equipment malfunctions

- Raw material quality issues

- Process upsets

- Product contamination

5. How do you troubleshoot a problem that occurs during the production of defluorinated phosphate?

To troubleshoot a problem that occurs during the production of defluorinated phosphate, I would:

- First, I would try to identify the source of the problem.

- Once I have identified the source of the problem, I would then try to find a solution.

- If I am unable to find a solution, I would then escalate the problem to my supervisor.

6. What are the safety precautions that must be taken when working with defluorinated phosphate?

- The safety precautions that must be taken when working with defluorinated phosphate include:

- Wearing personal protective equipment, such as gloves, goggles, and a respirator

- Working in a well-ventilated area

- Avoiding contact with skin and eyes

- Following all company safety procedures

7. What are the environmental regulations that apply to the production of defluorinated phosphate?

- The environmental regulations that apply to the production of defluorinated phosphate include:

- The Clean Air Act

- The Clean Water Act

- The Resource Conservation and Recovery Act

8. What are the future trends in the defluorinated phosphate industry?

- The future trends in the defluorinated phosphate industry include:

- An increasing demand for defluorinated phosphate

- The development of new and more efficient production processes

- The adoption of more stringent environmental regulations

9. What are your strengths and weaknesses as a Defluorinated Phosphate Production Supervisor?

My strengths as a Defluorinated Phosphate Production Supervisor include:

- My technical expertise in the production of defluorinated phosphate

- My strong leadership and communication skills

- My ability to troubleshoot problems and find solutions

- My commitment to safety and environmental compliance

My weaknesses as a Defluorinated Phosphate Production Supervisor include:

- My lack of experience in managing a large production team

- My limited knowledge of the environmental regulations that apply to the production of defluorinated phosphate

10. What are your salary expectations?

My salary expectations for this position are $75,000 to $90,000 per year.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Defluorinated Phosphate Production Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Defluorinated Phosphate Production Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Defluorinated phosphate production supervisors are responsible for all aspects of a defluorinated phosphate production facility. The primary role is to monitor production and ensure that quality standards are maintained. They also supervise a team of operators and maintain a safe and efficient work environment. Some key responsibilities include:

1. Production Management

Supervises and manages the production of defluorinated phosphate according to established quality standards and production schedules

- Monitors and adjusts process parameters to optimize production efficiency and product quality

- Troubleshoots and resolves production issues to minimize downtime and maintain operational efficiency

2. Quality Control

Conducts quality checks on incoming raw materials and finished products to ensure compliance with specifications

- Maintains and calibrates production equipment and instruments to ensure accuracy and reliability

- Implements quality control procedures and maintains records to ensure traceability and compliance

3. Team Management

Supervises and manages a team of operators, providing guidance, training, and performance evaluations

- Communicates effectively with team members to ensure clear understanding of roles and responsibilities

- Provides training and development opportunities to enhance team skills and knowledge

4. Safety and Environment

Ensures compliance with safety regulations and environmental standards throughout the production facility

- Conducts regular safety inspections and implements corrective actions to minimize risks

- Manages waste disposal and environmental monitoring programs to minimize environmental impact

Interview Tips

Preparing for an interview for a defluorinated phosphate production supervisor position requires a combination of technical knowledge and an understanding of leadership and management principles. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. This will give you a good understanding of the company’s culture, values, and expectations. It will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages to learn about their products, services, and recent news.

- Read industry publications and articles to stay up-to-date on the latest trends and developments.

2. Practice Your Answers

Once you have a good understanding of the company and position, practice answering common interview questions. This will help you feel more confident and prepared during the actual interview.

- Prepare responses to questions about your experience, skills, and qualifications.

- Practice answering questions about your leadership style and how you handle challenging situations.

3. Be Enthusiastic and Professional

First impressions matter, so it is important to be enthusiastic and professional during the interview. Dress appropriately, arrive on time, and make eye contact with the interviewer.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Maintain a positive attitude throughout the interview and show that you are eager to learn and contribute.

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to clarify any information that you may have missed during the interview.

- Ask questions about the company’s culture, values, and long-term goals.

- Inquire about the specific responsibilities of the role and how you can contribute to the team.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Defluorinated Phosphate Production Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Defluorinated Phosphate Production Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.