Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dehydrogenation Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dehydrogenation Supervisor so you can tailor your answers to impress potential employers.

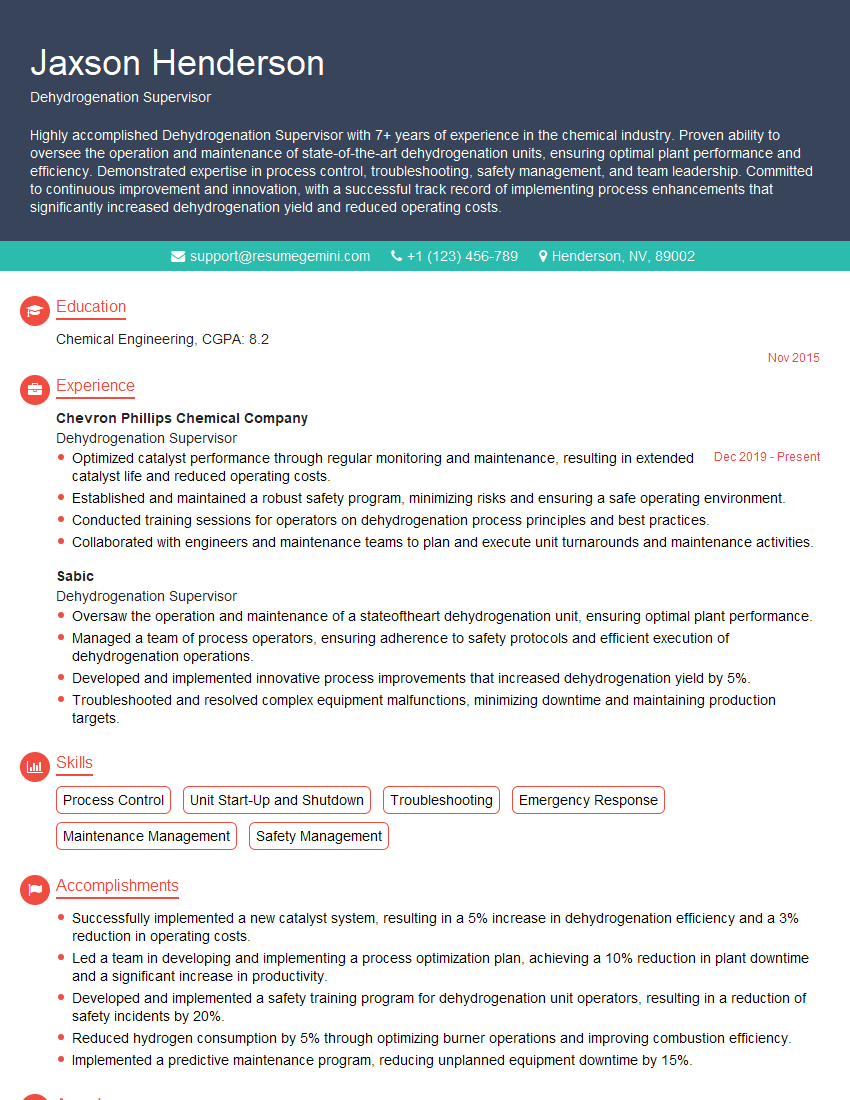

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dehydrogenation Supervisor

1. How do you ensure the purity of the final product in the dehydrogenation process?

- Monitor feedstock purity and implement strict impurity control measures.

- Optimize reaction conditions to minimize side reactions and byproduct formation.

- Employ advanced purification techniques, such as distillation and chromatography.

- Implement quality control protocols throughout the process to track and maintain product specifications.

2. Explain the role of catalyst selection and how it impacts the efficiency of the dehydrogenation process.

Catalyst Properties

- Activity: Ability to promote the desired reaction.

- Selectivity: Ability to minimize side reactions.

- Stability: Resistance to deactivation under reaction conditions.

Catalyst Selection Considerations

- Feedstock composition and reaction conditions.

- Desired product purity and yield.

- Catalyst availability, cost, and efficiency.

3. Describe the importance of temperature control in the dehydrogenation process, and discuss the consequences of deviations from the optimal temperature range.

- Optimal temperature range ensures high conversion rates and product selectivity.

- Higher temperatures promote unwanted side reactions and catalyst deactivation.

- Lower temperatures decrease reaction rates and yield.

- Temperature deviations can result in reduced product quality, increased energy consumption, and equipment damage.

4. Discuss the safety considerations and risk management strategies associated with the dehydrogenation process.

- Identify potential hazards, such as flammable gases, high temperatures, and pressure.

- Implement safety protocols and emergency response plans.

- Train operators on safe operating procedures and hazard recognition.

- Monitor process parameters closely to minimize risks.

5. Explain the principles of process optimization in the dehydrogenation process, and describe the key performance indicators (KPIs) used to measure improvement.

- Identify bottlenecks and areas for improvement.

- Monitor and analyze process data to optimize feedstock composition, temperature, and catalyst parameters.

- KPIs: Conversion rate, product yield, purity, energy consumption, and maintenance costs.

6. Describe the maintenance and troubleshooting procedures for the dehydrogenation unit, including preventative maintenance strategies.

Preventative Maintenance

- Scheduled inspections and cleaning.

- Monitoring equipment performance and identifying potential issues.

- Routine calibration and replacement of critical components.

Troubleshooting

- Analyze process data and identify deviations from normal operation.

- Determine the root cause of problems and implement corrective actions.

- Collaborate with engineers and maintenance personnel to resolve issues efficiently.

7. Discuss the challenges and complexities of managing a team of operators in the dehydrogenation unit, and describe your approach to promoting collaboration and productivity.

- Establish clear expectations and roles.

- Foster a supportive and collaborative work environment.

- Provide regular training and development opportunities.

- Recognize and reward individual and team achievements.

8. Explain the importance of environmental compliance in the dehydrogenation process, and describe the measures you have taken to minimize the environmental impact of your operations.

- Monitor and reduce wastewater, air emissions, and waste generation.

- Employ energy-efficient technologies and processes.

- Train operators on environmental best practices.

- Collaborate with regulatory agencies and stakeholders.

9. Discuss the emerging trends and advancements in the dehydrogenation industry, and explain how you stay up-to-date with these developments.

- Attend industry conferences and workshops.

- Read technical literature and research papers.

- Network with peers and experts in the field.

- Explore new technologies and innovations.

10. Explain your understanding of the role of the Dehydrogenation Supervisor, and describe your qualifications and experience that align with the responsibilities of this position.

- Responsible for overseeing all aspects of the dehydrogenation unit.

- Qualifications: Advanced degree in chemical engineering or related field, several years of experience in dehydrogenation operations.

- Experience: Managing teams, implementing process optimizations, ensuring safety and compliance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dehydrogenation Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dehydrogenation Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Dehydrogenation Supervisor is responsible for leading and overseeing the operation of the dehydrogenation unit to produce high-quality products in a safe, efficient, and environmentally compliant manner.

1. Manage and Supervise the Dehydrogenation Unit

Ensure that the unit is operated in a safe and efficient manner according to established procedures and guidelines

- Monitor and control process variables to optimize production and maintain product quality

- Identify and troubleshoot operational issues and take corrective actions to minimize downtime and product losses

2. Ensure Safety and Compliance

Establish and maintain a safe working environment by adhering to all safety protocols and procedures

- Conduct regular safety inspections and audits to identify potential hazards and implement corrective measures

- Train and supervise operators on safe work practices and emergency response procedures

3. Optimize Production and Efficiency

Analyze production data and identify areas for improvement in efficiency and yield

- Develop and implement strategies to reduce operating costs and maximize production output

- Evaluate new technologies and equipment to enhance the unit’s performance

4. Manage Personnel and Communication

Lead and motivate a team of operators and maintenance personnel to achieve unit objectives

- Provide clear instructions, training, and feedback to ensure effective communication and coordination

- Communicate regularly with management and other departments to provide updates on unit performance and address any concerns

Interview Tips

Preparing for an interview for the role of Dehydrogenation Supervisor requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company’s background, mission, and values to demonstrate your interest and understanding of the organization.

- Review the job description to identify specific requirements and expectations for the role.

- Explore the company’s website and social media pages to gather insights into their culture and industry standing.

2. Highlight Your Technical Expertise

Showcase your in-depth knowledge of dehydrogenation processes, unit operations, and optimization strategies.

- Provide specific examples of your experience in managing and troubleshooting dehydrogenation units.

- Discuss your knowledge of process control systems, instrumentation, and automation.

3. Emphasize Safety and Compliance

Demonstrate your commitment to safety and environmental compliance by sharing your experience in implementing and maintaining safety protocols.

- Highlight your understanding of industry regulations and standards.

- Discuss your experience in conducting safety inspections, training, and emergency response planning.

4. Showcase Your Leadership and Communication Skills

Effectively convey your ability to lead and motivate a team, and communicate clearly with management and colleagues.

- Provide examples of your experience in managing and developing a team in a similar industry setting.

- Emphasize your ability to communicate complex technical information to both technical and non-technical audiences.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dehydrogenation Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!